Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

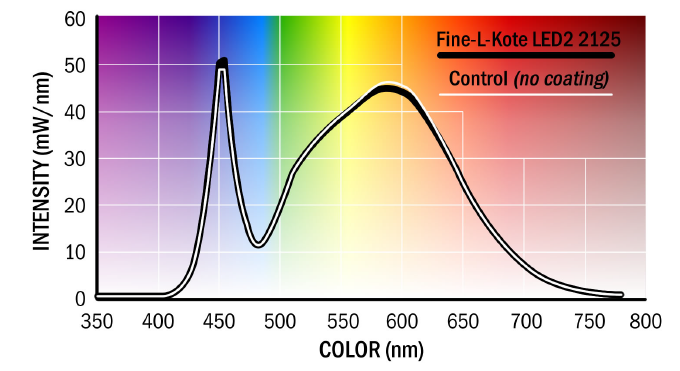

• Transparent to visible wavelengths, will not block or change light intensity or wavelength

• Exceptional dirt, dust, and soil repellency; surfaces remain clean longer

• Extends component life by protecting against adverse environments

• Good insulation properties help with circuit insulation characteristics, excellent flexibility minimizes thermal stress

• Resists moisture, salt, fungus, corrosive vapors, and severe environments

• Engineered to withstand heat generated by electronic circuitry as well as climatic temperature extremes

• Meets IPC-CC-830B, Type SR without UV traceability

• UL94 V0 flammability rating

• Room temperature moisture cure, can be heat accelerated

• RoHS compliant

Applications & Uses

- Markets

- Application Area

- Application Method

- Cure Method

- Applications

• LED Displays and controls

• Data Communications

• Instrumentation

• Automotive Manufacturing

• Marine Manufacturing

• Process Control- Usage Instructions

Spray Application: Apply top to bottom, allowing coating to flow evenly around components. Rotate PCB 90º and repeat application. Rotate and apply coating two additional times, then allow board to cure. If additional thickness is desired, apply additional coatings. When using liquid spray with automatic dispensing equipment, adjustments may be required in application rate and viscosity.

Dip Application: Using automatic equipment or hand immersion technique, slowly immerse PCB into the coating and remove slowly. Use an average rate of approximately 1 foot per minute. After allowing the board to cure, process may be repeated to achieve desired thickness.

Brush Application: Evenly apply coating to areas desired at thickness required. Allow time for curing before reapplying to achieve a thick coating. Use WonderMASK to protect components during conformal coating process. After application, cured Fine-L-KoteTM may be removed using Techspray Conformal Coating Removal Pen (2510-N or 2510-P).Moisture Resistance Excellent Soil resistance Excellent Removability Excellent Ease of Repair Excellent Flexibility Excellent Adhesion Excellent Abrasion Resistance Fair Solvent Resistance Good

Properties

- Physical Properties

- Typical Properties

- Notes

*Properties for cured resin only.

†Full physical and electrical properties obtained after 7 days.

| Value | Units | Test Method / Conditions | |

| Flash Point (Closed Cup) | 26ºF (-3.3ºC) | — | — |

| Specific Gravity (water = 1, 68ºF) | 0.83 | — | — |

| VOC (Carb) | 11.7 | % | — |

| VOC (SCAQMD) | 108.0 | g/L | — |

| VOC ( Federal) | 11.7 | % | — |

| Value | Units | Test Method / Conditions | |

| Coverage (1 mil dry film, 1 gal liquid, 67 m²) | 723.0 | ft² | — |

| Tack Free Time | 30.0 | minutes | — |

| Full Cure† Time (Accelerated , 170ºF / 77ºC) | 8.0 | Hrs | — |

| Full Cure† Time (2-step, 90°F / 32°C) | 30.0 | minutes | — |

| Full Cure† Time (2-step, 199°F / 93°C) | 100.0 | minutes | — |

| Full Cure† Time (Ambient, 77ºF / 25ºC, 30-60% RH) | 72.0 | Hrs | — |

| Viscosity | 66-76 | cps | — |

| Solids | 43.0 | % | — |

| Hardness | 86.0 | shore A | — |

| UV Indicator | No | — | — |

| Operating Temperature Range* | -60 to 200 | °C | — |

| Volume Resistivity* | min. 1.4 x 10¹² | ohm – cm | — |

| Dielectric Strength | min. 720 | volts/mil | — |

| Dielectric Constant (100 Hz to 100 kHz) | 3.75, 3.85 | — | ASTM D150 |

| Dissipation Factor (100 Hz to 100 kHz)* | 1.017, 0.719 | — | ASTM D150 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Specifications

• IPC-CC-830B (w/o UV)

• UL94 flammability rating V-0

• MIL-STD 810G salt spray test

• IESNA LM-79-2008

• ANSI NEMA ANSLG C78.377:2015- Compatibility

Fine-L-KoteTM LED2 is generally compatible with most materials found on printed circuit boards. As with any chemical product, product/component compatibility must be determined on a non- critical area prior to use.

- Optical Clarity Validation

3rd party testing by Intertek, standards IESNA LM-79-2008 and ANSI NEMA ANSLG C78.377:2015.

Safety & Health

- Environmental Data

CFC 0.00% HCFC 0.00% Cl. Solv. 0.00% VOC 11.70% HFC 0.00% ODP 0 CFC, HCFC, CL. SOLV., VOC, and HFC numbers shown are the content by weight. Ozone depletion potential (ODP) is determined in accordance with the Montreal Protocol and U.S. Clean Air Act of 1990. The ODP of this product is 0.0. It is the sum of the ODP of the substances that may contribute to the depletion of stratospheric ozone, based upon the weight of each substance in the product’s formulation.

Environmental Policy

Techspray® is committed to developing products to ensure a safer and cleaner environment. We will continue to meet and sustain the regulations of all federal, state and local government agencies.

Packaging & Availability

- Packaging and Availability

2125-5G 5 Gallon Liquid

Storage & Handling

- Shelf Life

- 9 months. From Production Date