Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

• Fastest Cure - Dry to Touch in 3 Minutes!

• Faster Throughput without Capital Investment

• Thick Coating - One-Pass Application

• Fast & Easy Rework & Repair

• IPC-CC-830 Tested

• UL94 V-0 Rated

• Crystal Clear & Glossy Finish

• UV Indicator for Black Light QC Inspection

• MEK, Toluene & Xylene Free

• Adjustable spray head (Aerosol)

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Applications

Electronic Assemblies for...

• Automotive

• Aviation

• Consumer Electronics

• Appliances • Industrial Meters & Control- Usage Instructions

Spray Application: Apply top to bottom, allowing coating to flow evenly around components. Repeat application 3 additional times from varying directions to prevent component shadowing. Then allow board to cure. If additional thickness is desired, apply additional coatings. When using liquid spray with automatic dispensing equipment, adjustments may be required in application rate and viscosity.

Dip Application: Using automatic equipment or hand immersion technique, slowly immerse PCB into the coating and remove slowly. Use an average rate of approximately 1 foot per minute. After allowing the board to cure, process may be repeated to achieve desired thickness.

Brush Application: Evenly apply coating to areas desired at thickness required. Allow time for curing before reapplying to achieve a thick coating. Use WonderMASK to protect components during conformal coating process. After application, cured Fine-L-KoteTM may be removed using Techspray Conformal Coating Removal Pen (2510-N or 2510-P).

Properties

- Physical Form

- Appearance

- Pass

- Typical Properties

- Cured Properties

- Chemical Components

- Acrylic Polymer (non-hazardous)

n-Propyl acetate CAS#109-60-4 Acetone CAS#67-64-1 n-Heptane CAS#142-82-5

| Value | Units | Test Method / Conditions | |

| Coating Flammability | V-0 | - | UL94/746E |

| Fluorescence | Pass | - | IPC-CC-830B 3.5.3 |

| Flammability | Pass | - | IPC-CC-830B 3.5.6 |

| Fungus Resistance | Pass | - | IPC-TM-650 2.6.1.1 |

| Flexibility | Pass | - | IPC-TM-650 2.4.5.1 |

| Dielectric Withstand Voltage | Pass | - | IPC-TM-650 2.5.7.1 |

| Moisture & insulation resistance | Pass | - | IPC-TM-650 2.6.3.4 |

| Thermal shock | Pass | - | IPC-TM-650 2.6.7.1 |

| Temperature Humidity Ageing | Pass | - | IPC-TM-650 2.6.11.1 |

| Value | Units | Test Method / Conditions | |

| Dielectric Strength | 1000.0 | volts | ASTM D-149, IPC-TM-650 2.5.6.1, Rev. A |

| Adhesion | 5B | - | ASTM D-3359 |

| Film Hardness | 2B | - | ASTM D-3363 |

| Film Thickness (1 dip, 0.001”) | 1.0 | mil | ASTM D-1005 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Coverage

- (1mil dry film)1 aerosol can = 14ft2 (1.3M2)1 gal. lquid = 272ft2 (25.3M2)

- Cure Profile

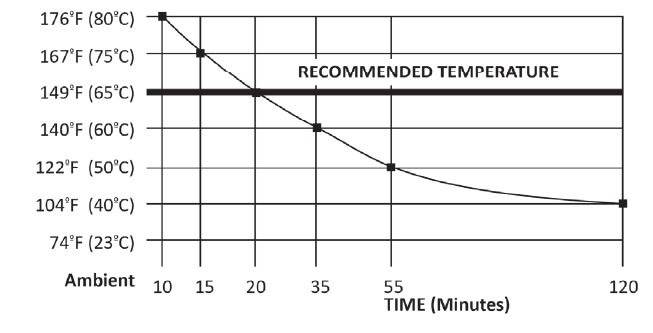

Accelerated Cure: 20 minutes @ 149°F / 65°C

Ambient Cure: 15 hours @ 74°F / 23°C (ambient temp)

Tack-Time (dry to touch): 3 minutes @ 74°F / 23°C (ambient temp)

Cure time depends on a number of factors, including the method and thickness of application. Dilution will also change the cure profile. 149°F / 65°C is recommended as the best accelerated temperature to optimize leveling, providing the smoothest possible finish. A faster cure may be achieved, but should be thoroughly tested first.

adf- Competitive Comparison

Chemtronics CTAR-12 MG 419B Loctite 3900 Humiseal 1B73 Humiseal 1B31 Techspray 2108-12S Techspray 2103-12S YES NO NO YES YES YES YES MIL-I-46058C/IPC-CC-830 YES NO NO YES NO NO YES UL94 Tested V-0 Rated 33 10 6 33 9 17 3 Tack-Free Time (minutes) MEK Toluene, Xylene Toluene MEK, Toluene MEK, Toluene NO NO Contains MEK, Toluene, Xylene50 50 50 50 50 200 200 Threshold Limit Value (TLV) - Lower is more hazardous4B 6B 4B 2B 4B 4B 2B Hardness (Gardner Pencil) - Lower is harder4B 4B 5B 4B 4B 5B 5B Adhesion (ASTM D3359) - Higher is betterHigh gloss, uneven spray pattern, large amount of material Uneven gloss, orange peel texture, very soft spray pattern Good gloss, good level, med cone pattern Good gloss, good level, very wide pattern Good gloss, patchy level, good pattern Med gloss, even level, soft/med spray pattern High gloss, fast/even level, soft/med spray pattern Observations - Chemical Compatibility - Industrial Chemicals

INDUSTRIAL CHEMICALS EFFECT CAS # Methanol Soften 67-56-1 Ethanol Dissolution 64-17-5 IPA Dissolution 67-63-0 70% IPA Dissolution 67-63-0 50% Ethanol No effect 64-17-5 DPM Dissolution 34590-94-8 Glycol ether EB Dissolution 111-76-2 THF Dissolution 109-99-9 Acetone Dissolution 67-64-1 n-propyl acetate Dissolution 109-60-4 t-butyl acetate Dissolution 540-88-5 Hexane Dissolution 110-54-3 Heptane Soften 142-82-5 Cyclopentane Dissolution 287-92-3 Cyclohexane Dissolution 110-82-7 T oluene Dissolution 108-88-3 Trans-dce Dissolution - Chemical Compatibility - Household Chemicals

HOUSEHOLD CHEMICALS EFFECT EXAMPLE OF US BRAND NAME 5% Acetic acid No effect Heinz Vinegar 0.1N Hydrochloric acid No effect Lime-A-Way Toilet Bowl Cleaner 50% Nitric acid No effect Parson's solution No effect Windex 0.1N Potassium hydroxide No effect 10% Liquid Plumber 45% Potassium hydroxide No effect Liquid Plumber d-limonene Dissolution Orange Glo Chlorox neat No effect Chlorox Chlorox 1:1 No effect 50% Chlorox Chlorox 1:4 No effect 20% Chlorox Pine-Sol Lemon No effect Pine-Sol Lemon Pro 409 No effect 409 Professional In most cases, Techspray® corporate test methods (TS designation) correspond to standard ASTM Copies of Techspray® corporate test methods are available upon request.

Packaging & Availability

- Thinning/Removal

Techspray® coatings can be thinned to meet production requirements using Conformal Coating Thinner (2105). Conformal Coating Remover (2510) is also available for rework and repair, although coating is often just burnt through in the soldering process for spot repairs. Techspray® coatings contain Opti/Scan to allow quality control inspection of coverage and evenness of the coating on a PCB. A coated board can passed under a standard, low-cost UV (black) light, and the coated areas glow. The brighter the glow, the thicker the coating.