Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Properties

- Extremely high modulus

- High abrasion resistance

- Excellent shrinkage behavior

- High UV resistance

- High chemical resistance

- Superior thermal-aging performance

- No brittleness at cryogenic temperatures

- Superb strength-to-weight capabilities

- Extremely high modulus

- High abrasion resistance

- High impact resistance

- High UV resistance

- High chemical resistance

- Superior thermal-aging performance

- No brittleness at cryogenic temperatures

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

- Often located far away from replacement nets or maintenance operatives, aquaculture nets need to be built to last and offer total reliability to fish farmers. Netting durability can directly impact on the netting operation quality for aquaculture farmers.

- Protective composites made from Endumax® are used in insert plates, protective panels and helmets, and offer a very high energy absorption capability, giving them a remarkably high stopping power for bullets and fragments.

- The excellent impact resistance of Endumax® in ballistic applications, combined with its stiffness and low weight, can easily be translated into other fields. For instance, air cargo containers need to be as light, strong and as impact resistant as possible, to protect cargoes, save fuel and reduce maintenance costs.

- Endumax® film offers a very high modulus, good UV resistance, and good flex fatigue, making it very suitable for use in laminated sails. Sails made of Endumax® keep their shape even under severe forces, they are not damaged by ultra-violet light, and they can be endlessly folded and unfolded.

- Endumax® has excellent sound-damping properties, so in combination with its high modulus and low density, it is ideal for use in loudspeakers. Endumax® speakers will reach higher frequencies than similar sized speakers of other materials.

- With its unique weight-for-weight strength and areal weight (0.97 g/cm²), Endumax® is an excellent choice for manufacturers of ropes and cables. Because of the f ilm shape Endumax® is intrinsically more durable than any UHMWPE fiber.

Properties

- Typical Properties

- Extremely High Modulus

For a material of low density, Endumax® has an unparalleled high modulus, enabling performance that is above and beyond other reinforcement materials.

- Chemical and Fire Resistance

The unique chemical and physical structure of Endumax® enables performance even under challenging conditions that include exposure to fire and chemicals.

- Superior Weathering

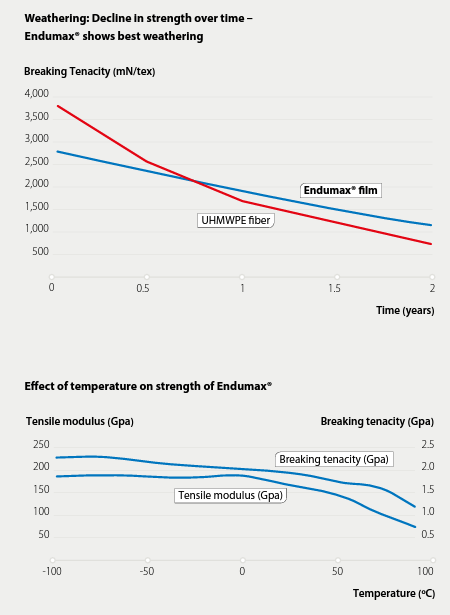

In every weather condition, Endumax® will keep on performing from start to finish. Unlike other reinforcement yarns, Endumax® demonstrates much lower performance loss when exposed to ultraviolet light. Endumax® ensures the lifetime of its end product.

| Value | Units | Test Method / Conditions | |

| Breaking Strength | 225.0 | N lbs | — |

| Breaking Tenacity | 2.4 | N/tex | — |

| Density | 0.97 | g/cm3 | — |

| Elongation at Break | 1.8 | % | — |

| Linear Density | 950.0 | dtex | — |

| Modulus | 170.0 | GPa | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

Performance at extreme temperatures.

Packaging & Availability

- Availability

Endumax® film TA23 is available with a standard thickness of approximately 50 - 60 µm and in three main widths: 2 mm, 4 mm and 133 mm.