Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

High tensile strength, high modulus and excellent resistance to heat and chemicals, especially acids and alkalis, Technora® filament yarn can offer added value to ropes and cables, hoses, protective workwear, civil engineering products and sails, as well as in rubber reinforcement.

- Excellent resistance to heat degradation

- Excellent tensile strength and fatigue resistance

- Superior resistance to chemicals

- Adjustable to different applications

- Long-term dimensional stability

- High strength-to-weight ratio

- High modulus

- High dimensional stability: low creep, small negative thermal expansion coefficient

- Excellent thermal stability: effective over an extremely wide temperature range, no melting point, high heat stability, low heat conductivity

- Good abrasion and fatigue resistance

- High cut resistance

- Excellent chemical resistance

- Low flammability

- Electrically non-conductive

- Long, well-defined lifetime

Applications & Uses

- Markets

- Applications

- Composites End Use

- Applications

Technora® filament yarn adds value to numerous applications – including power-transmission belts for automotive, industrial and agricultural applications, as well as hoses, ropes and cables, flexible pipes, rubber products, protective clothing and composites – and is available in a wide range of linear densities and surface treatments.

- Applications

- Technora® provides short-cut fiber compound reinforcement, as well as twisted cords and fabrics, in a wide range of power-transmission belts for automotive, industrial and agricultural applications. Specifically, Technora® enhances a number of key rubber compound characteristics, such as resistance against abrasion, fatigue, puncture and tears, while also improving strength and hardness.

- Technora® is used as a hose-reinforcing yarn in a wide range of automotive hose applications, including radiator hoses, transmission-oil-coolant hoses, air-conditioning hoses and fuel hoses.

- With its unique combination of properties, Technora® yarn has a proven track record in challenging and demanding fields – including the mining, offshore and leisure industries – reinforcing and strengthening ropes and cables and making them safer and easier to use.

- The superior hydrolysis of Technora®, combined with its excellent thermal, chemical and fatigue resistance, is increasingly valued in the offshore oil & gas industry

Properties

- Physical Form

- Typical Properties

- Properties

All Technora® filament yarns offer several high-performance properties, including exceptional strength and a thermal decomposition threshold of up to 500ºC.

- Properties

Unlike other high-performance aramids, Technora® offers both excellent primary properties, such as tenacity and strength, and secondary properties, such as heat and abrasion resistance.

- Mechanical Properties

- Technora® yarns have a very high strength, offering a tensile strength that is three to four times higher than polyester and polyamide yarns and eight times higher than steel on a weight-for-weight basis.

- Technora® yarns not only offer excellent fatigue resistance, with the ability to absorb dynamic loads for long periods of time, they also deliver very good abrasion resistance compared with many fibers, including other aramid solutions.

- The effects of temperature on the lifetime of Technora® yarn are relatively limited.

- Dimensional Stability

The dimensional stability of the reinforcing material is often key in many applications. The high modulus of Technora® ensures that the end-use product shows minimal deformation under a wide range of loading conditions.

- Thermal Properties

The unique mechanical properties of Technora® make it suitable for use in applications over a very wide temperature range. In particular, Technora® has no melting point, and only starts to decompose once the ambient temperature reaches 500 °C (932 °F). For heat-resistant applications, exposure to temperatures above 250 °C (482 °F) is not recommended, to ensure fit-for-use strength retention.

- Chemical Resistance

The unique molecular and crystalline structure of Technora®, in conjunction with the closed morphology of its filaments, prevents chemicals from penetrating the polymer structure of the material. Resistance to organic chemicals is therefore excellent, while resistance to inorganic chemicals varies according to pH value.

| Value | Units | Test Method / Conditions | |

| Density | 3.2 -3.5 | g/cm | — |

| Tensile Strength | 2.3-2.5 | GP | — |

| Tenacity | 65-85 | N/tex | — |

| Modulus | 3.9-45 | GPa | — |

| Elongation at Break | 1.9 | — | — |

| Moisture Content | 500.0 | % | — |

| Decomposition or Melting Temperature | 932.0 | °C | — |

| Limiting Oxygen Index (LOI) | 25 - 40 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

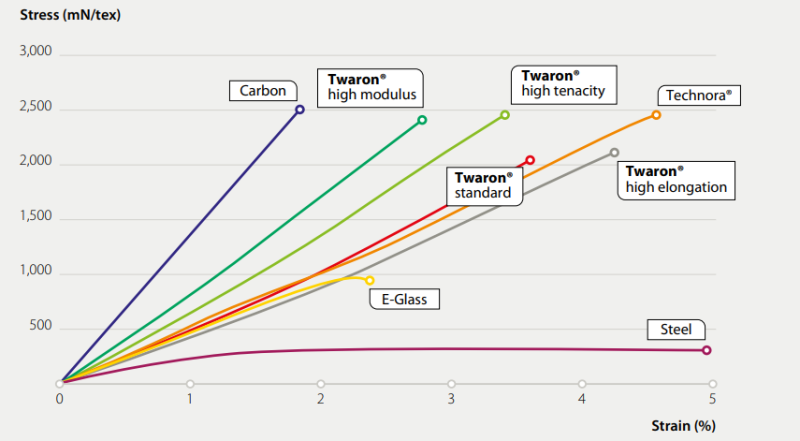

N.B. As the data in the figure above originate from a variety of sources, they may be subject to deviations resulting from different test methods and/or conditions.

Stress/strain curve of various materials

Packaging & Availability

- Availability

- Technora® filament yarn is supplied in yarn counts from 220dtex to 2500dtex in its natural golden color and also comes in dope-dyed black and gray.

- Technora® filament yarn is available with either its natural, dark-yellow coloring or in black.

- Black Technora® is used in applications where special requirements exist regarding the appearance of the yarns.