Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Inherent resistance to heat and flame

- Excellent cut resistance

- Superior strength-to-weight

- Exceptional flexibility

Applications & Uses

- Markets

- Applications

- Applications

Twaron® staple fiber is suitable for the most common spinning processes, such as the cotton-spinning system or the Dref system, as well as non-woven processes, such as needle-felt or hydro entanglement.

- Uses

Twaron® staple fibers are used in textile applications for gloves, and for apparel that protects against heat and cuts.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.44-145 | g/cm | — |

| Tensile Strength | 27-3.6 | GP | — |

| Tenacity | 1.9-25 | N/tex | — |

| Modulus | 60-145 | GPa | — |

| Elongation at Break | 23-42 | — | — |

| Moisture Content | 2 - 7 | % | — |

| Decomposition or Melting Temperature | 500.0 | °C | — |

| Limiting Oxygen Index (LOI) | 29-40 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- A Unique Combination of Properties

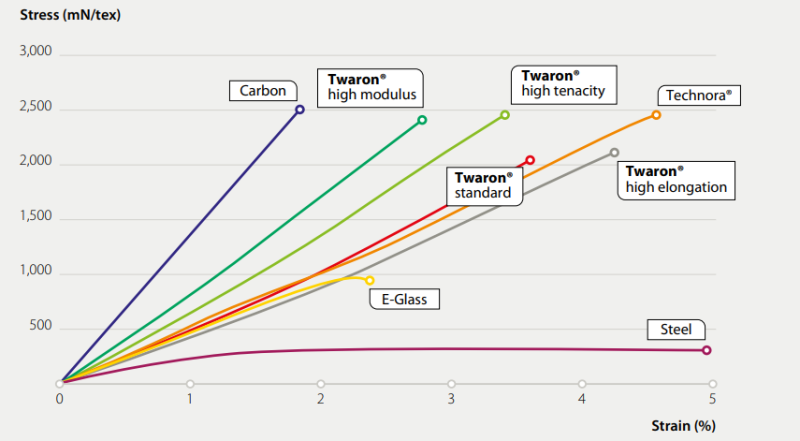

Mechanical properties: Twaron® yarns have high strength, offering a tensile strength that is two to three times higher than polyester and polyamide yarns, and up to seven times higher than steel on a weight for weight basis. The table illustrates the main mechanical properties in comparison with a selection of other high-performance materials as reported under standard conditions. Twaron® retains its core mechanical properties across a wide temperature range. These properties are available for reinforcement purposes for a well-defined lifetime of Twaron® yarn. This lifetime is determined by the specific combination of load and temperature. In general, the higher the load and/or the operating temperature, the shorter the lifetime of Twaron® yarn. Using accepted safety factors in the applications, Twaron® enables a long economic life for the end product. However, long-term exposure to UV light should be avoided, since this will result in discoloration and negatively influence the mechanical properties of the yarn.

Dimensional stability: The dimensional stability of reinforcing material is often a key factor in many applications. The high modulus of Twaron® ensures that the end product shows minimal deformation under a wide range of loading conditions. What’s more, the end product retains its required dimensions over a long period of time due to the very low and quickly diminishing creep behavior of Twaron®. In addition, Twaron® has a low, negative thermal expansion coefficient of a few ppm/°C, which contributes to the material’s high dimensional stability. Finally, Twaron® does not shrink when exposed to hot air.

Thermal properties: Twaron® has no melting point and will only start to decompose at temperatures of 500 °C (932 °F) and above. For heat-resistant applications, the recommended ambient temperature should not exceed 250 °C (482 °F) in order to ensure fit-for-use strength retention. Twaron® also largely maintains its mechanical properties at very low temperatures of -200 °C (-328 °F) or below. This makes Twaron® usable in applications across a very wide temperature range. Furthermore, the thermal isolation behavior of Twaron® products is excellent due to the very low heat conductivity of the yarn. In addition, Twaron® has a high limiting oxygen index (LOI). This means that it ceases to burn as soon as it is removed from the flame, limiting the spread of fire when Twaron® reinforcement is in use.

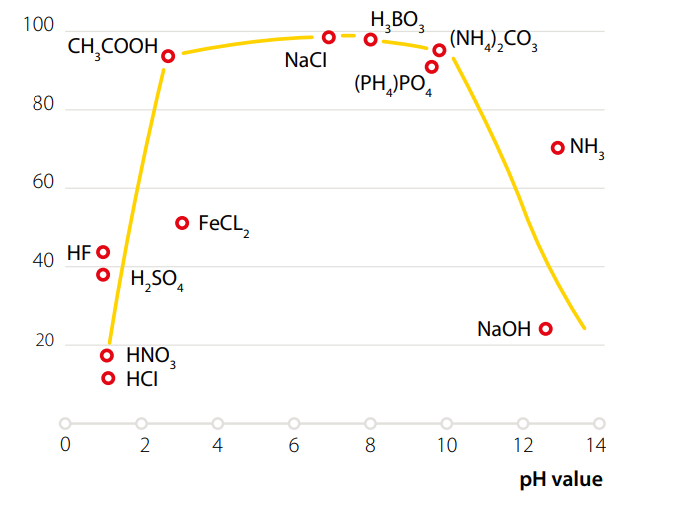

Chemical resistance: The high crystallinity and strong intermolecular interactions of Twaron® prevent chemicals from penetrating the polymer structure. Resistance to organic chemicals is good to excellent, while resistance to inorganic chemicals varies according to the pH value. Highly acidic or alkaline chemicals may cause hydrolytic degradation. Concentrated solutions of strong acids and strong bases will result in hydrolytic degradation.- Technical Details

Twaron® resistance to chemical attack, exposure time: three months in water at room temperature.

N.B. As the data in the figure above originate from a variety of sources, they may be subject to deviations resulting from different test methods and/or conditions.

Packaging & Availability

- Availability

- Twaron® staple fiber is available in natural yellow and black, as well as in various fiber lengths and linear densities. As a specialty product, Twaron® staple fiber is also available as Microdenier, which allows manufacturers to offer added comfort to users.

- Several specified staple fiber lengths can be supplied (40, 50, 60 mm). In addition, a various-cut staple fiber product is available with fiber lengths of between 76 mm and 100 mm. The linear density of the staple fibers can be selected from 0.9, 1.7 and 2.5 dtex products.

- For black staple fibers, linear densities of 1.7 and 2.5 dtex are available.