Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Polymer Name

- Reinforcement Material

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Ready-to-Use Product Features

- Advantages

- Major cost reduction

- Signifi cant weight saving

- High bending stiff ness

- Energy absorbent

- Resistant to moisture, acids and bases

- Easy resource-friendly converting

- 100 % recyclable

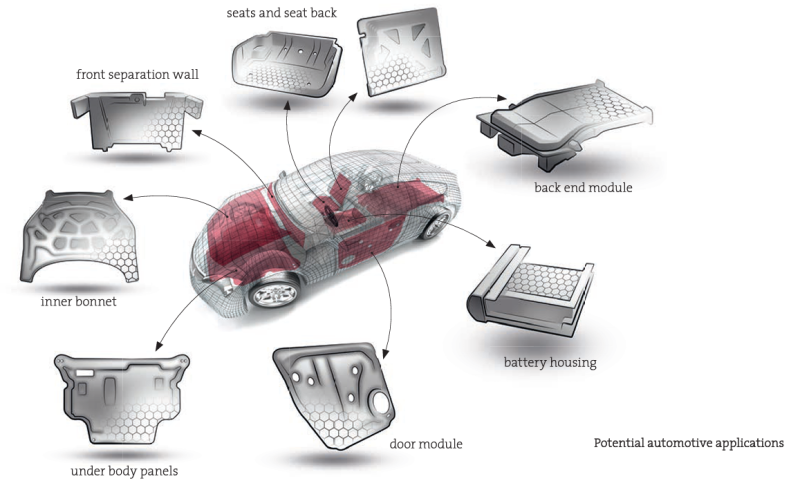

Applications & Uses

- Markets

- Composites End Use

- Applications

Vehicles & Automobiles

Properties

- Physical Form

- Physical Properties

- Typical Properties

- Fire Resistance

Normally inflammable, higher grades of fire-resistance can be obtained in sandwich elements when using specialized surface modification.

- Chemical Resistance

Excellent resistance to water, most acids, bases and salt solutions.

| Value | Units | Test Method / Conditions | |

| Bending Stiffness (at 400 mm Span Length in 3PB Test, CD (L), MD (W)) | 590/475 | Nm | — |

| Compressive Strength (Z-direction) | 2 (290) | Mpa (Psi) | ASTM C365–57 |

| Compressive Modulus (Z-direction) | 25 - 45 (3626 - 6527) | Mpa (Psi) | ASTM C365–57 |

| Shear Strength (CD, L/MD, W) | 0.7/0.4 (101/58) | Mpa (Psi) | ASTM C273–61 |

| Shear Modulus (CD, L/MD, W) | 21/6 (3.045/870) | Mpa (Psi) | ASTM C273–61 |

| Temperature Range for Processing | -30 to +80 | °C | — |

| Temperature Range for Application | Short term to +140 | °C | — |

| Thermal Conductivity | 0.065 | W/mk | — |

| Value | Units | Test Method / Conditions | |

| Standard Dimensions (CD, L x MD, W) | 1.200 x 2.500 | mm | — |

| Sandwich Thickness | 6 - 12 | mm | — |

| Skin Layer Thickness | 0.5 | mm | — |

| Core Thickness | 5 - 11 | mm | — |

| Cell Size | 4 - 5 | mm | — |

| Weight Per Unit Area | 2.400 - 3.240 | g/m² | — |

| Sandwich Density | 260 - 410 | kg/m³ | — |

| Core Density | 120 - 130 | kg/m³ | — |

| Tolerances MD (Machine Direction, W) | +10/-1 | mm | — |

| Tolerances CD (Cross Direction, L) | +2/-1 | mm | — |

| Tolerances Sandwich Thickness | +/-0.3 | mm | — |

| Tolerances Squareness | +/-0.2 | ° | — |

Regulatory & Compliance

- Certifications & Compliance

- Liability For Defects

All information provided herein is based on our current knowledge and experience. Due to the high number of possible infl uences during processing and application, the information does not release the processor from the necessity of carrying out his own investigations and tests. Information contained herein and explanations provided by ThermHex Waben GmbH In connection with this printed matter does not represent acceptance of a guarantee. Guarantee statements require special explicit written declarations on behalf of ThermHex Waben GmbH to be eff ective. The constitutions stated in this datasheet determine the properties of the delivery item extensively and conclusively. Application suggestions do not establish assurance of suitability for the recommended application.

We reserve the right to adapt the product to satisfy technical progress and new developments. We would be pleased to help with any enquiries including those related to special application issues. If the application for which our products are used is subject to statutory approval, the user is responsible for the procurement of such approval. Our recommendations do not release the user from the obligation of taking the possibility of impairments to third-party rights into account and of clarifying these if necessary. Furthermore we refer to our General Terms and Conditions, especially with regard to any possible liability for defects. If you are not in possession of our General Terms and Conditions we would be pleased to supply these on request.

Technical Details & Test Data

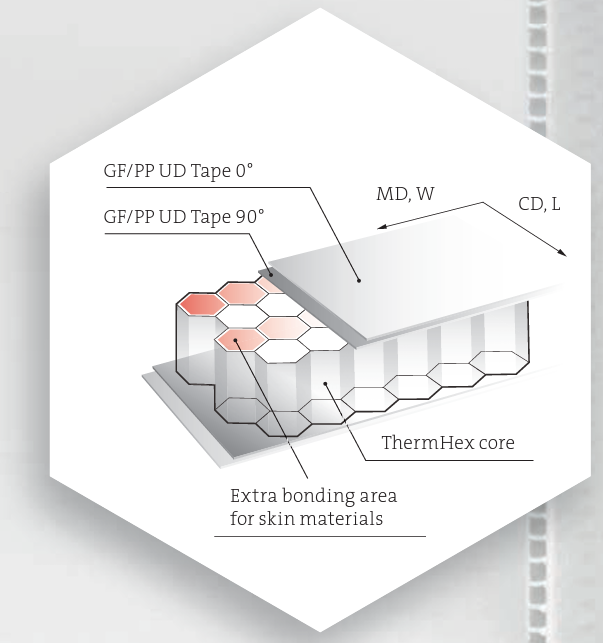

- Thermhex Organosandwich – The New Sandwich Material

The Organosandwich production is based on the patented ThermHex process. The process enables the continuous inline production of thermoplastic honeycomb cores in a fully automatic production line.

By using our lightweight Organosandwich weight savings of over 80 % are possible compared to a monolithic construction. In comparison to a monolithic organosheet laminate, a sandwich of the same stiff ness requires less number of layers, which means considerable cost savings when using the Organosandwich.

The Organosandwich consist of 0°/90° cross ply laminate skin layers made of continuous glass fi ber reinforced polypropylene (GF/PP). The folded honeycomb core material consists of a polypropylene as well. This allows an optimal bonding between core and skin layers in the lamination process by thermoplastic welding. The sandwich can be pressed locally to a monolithic laminate which allows the thermoforming of multi-curved shell structures and the pressing of pressure stable monolithic joining surfaces in one step. The pressed areas off er the possibility of functional integration by means of injection molding. Hence, complex lightweight parts can be produced very cost-effi cient in short cycletimes which is essential for many automotive applications.