Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Advantages

- Major cost reduction

- Significant weight saving

- High compression and shear strength

- Energy absorbent

- Resistant to moisture, acids and bases

- Easy resource-friendly converting

- 100% recyclable

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Markets & Applications

- Vehicle & Automobile

- Boat, Yacht & Ship

- Wind & Solar Energy

- Interior & Furniture

- Building & Construction

Properties

- Physical Form

- Typical Properties

- Material, Surface Finish & Standard Dimensions

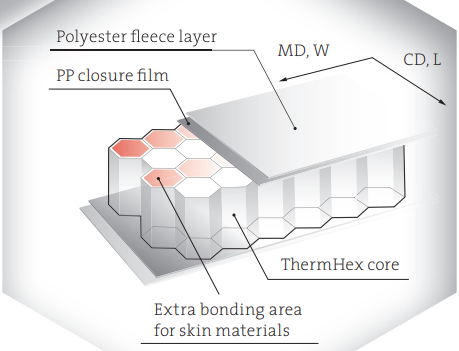

Core material Polypropylen Core thickness (in) 0,20 0,32 0,39 0,47 0,59 0,79 0,91 1,10 Cell size (in) 0,16 0,32 0,32 0,20 0,20 0,20 0,38 0,38 Surface finish -F Polypropylene barrier film

-N Polyester NonwovenStandard dimensions (in) 98.5 (MD, W) x 47.3 (CD, L)

or 96 (MD, W) x 48 (CD, L)

| Value | Units | Test Method / Conditions | |

| Density | 3.74 - 4.37 | lb / ft3 | — |

| Compressive Strength | 87 | psi | ASTM C365-57 |

| Compressive Modulus | 2.2 | ksi | ASTM C365-57 |

| Shear Strength (CD, L/MD, W) | 58/29 | psi | ASTM C273-61 |

| Thermal Conductivity | 0.06 | W/mK | — |

| Temperature Range Production | -198 | °F | — |

| Temperature Range in Operation | Short term to 284 | °F | — |

| Shear Modulus (CD, L/MD, W) | 2.1/0.7 | ksi | ASTM C273-61 |

Regulatory & Compliance

- Certifications & Compliance

- Liability For Defects

All information provided herein is based on our current knowledge and experience. Due to the high number of possible infl uences during processing and application, the information does not release the processor from the necessity of carrying out his own investigations and tests. Information contained herein and explanations provided by ThermHex Waben GmbH In connection with this printed matter does not represent acceptance of a guarantee. Guarantee statements require special explicit written declarations on behalf of ThermHex Waben GmbH to be eff ective. The constitutions stated in this datasheet determine the properties of the delivery item extensively and conclusively. Application suggestions do not establish assurance of suitability for the recommended application.

We reserve the right to adapt the product to satisfy technical progress and new developments. We would be pleased to help with any enquiries including those related to special application issues. If the application for which our products are used is subject to statutory approval, the user is responsible for the procurement of such approval. Our recommendations do not release the user from the obligation of taking the possibility of impairments to third-party rights into account and of clarifying these if necessary. Furthermore we refer to our General Terms and Conditions, especially with regard to any possible liability for defects. If you are not in possession of our General Terms and Conditions we would be pleased to supply these on request.

Technical Details & Test Data

- Thermhex PP Honeycomb Cores Offer to Producers of Sandwich Elements a New Generation of the Approved Core Material

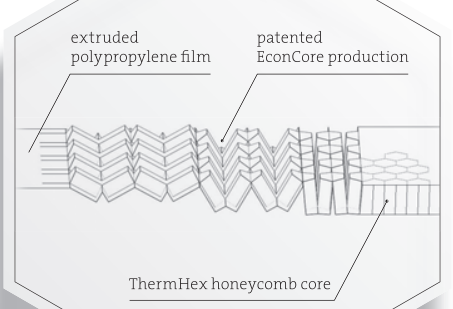

The innovative ThermHex technology for the continuous production of PP honeycomb cores supports the production of highly cost-efficient sandwich structures. Different from traditional production processes, the patented EconCore process allows for the production of PP honeycomb sheets in theoretically endless lengths. The low consumption of raw materials helps to save on resources and to reduce the carbon footprint.

ThermHex honeycomb cores are first finished with a polypropylene barrier film. This film prevents the resins to ingress into the open cells during converting and in this way assures stable mechanical properties in the finished part. At the same time, the quantity of resin needed for processing is reduced to a minimum. The second standard surface finish is a PET non-woven material, which enables an easy bonding of various types of skin materials with all common adhesives.