Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Polymer Name

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Background

Advantages:

- Weight savings of up to 80% compared to monolithic material possible

- Major cost reduction

- High bending stiffness

- High compressive and shear strength

- Energy absorbent

- Resistant to moisture, acids and bases

- Easy resource-friendly converting

The Organosandwich is a semi-finished panel that consists of two thin skin layers of fiber reinforced thermoplastic composites (organosheet) spaced by a thermoplastic honeycomb core to provide high stiffness at minimal weight, without the need of incorporating additional stiffening ribs as often required for parts based on monolithic organosheet.

The Organosandwich is particularly cost efficient as it is made in a continuous process: the skin layers are applied in-line and welded to the honeycomb core as it is produced.

In further production steps, especially with regards to the automotive industry, the Organosandwich can be further processed into final parts and functionalized within very short cycle times. A typical conversion method is compression molding whereas the functionalization can be realized by integrated injection over-molding.

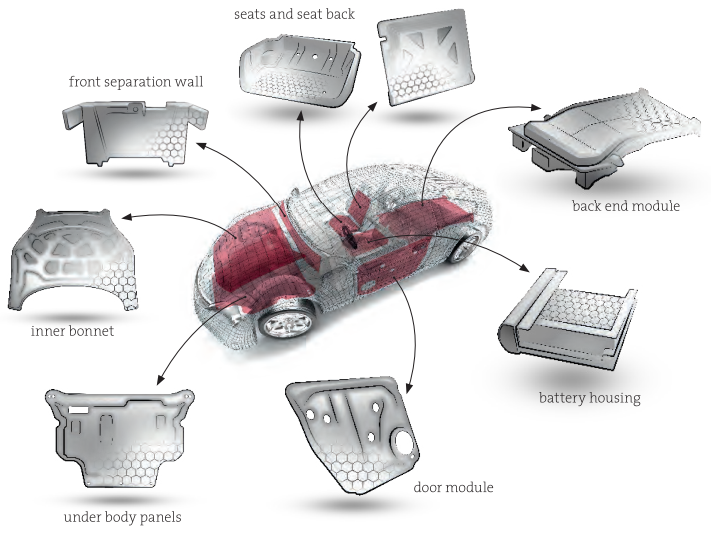

The Organosandwich is ideal for large series production of components for the automotive industry, where the performance, light-weighting and cost-efficiency need to meet together.

Applications & Uses

- Applications

- Compatible Reinforcements

- Composites End Use

- Composites Processing Methods

Properties

- Physical Form

- Typical Properties

- Product Information

- Temperature range: - 30 °C to + 80 °C; short term up to + 140 °C

- Fire-resistance: Normally inflammable, higher grades of fire-resistance can be obtained in sandwich elements when using specialized surface modification.

- Chemical resistance: Excellent resistance to water, most acids, bases and salt solutions.

- Standard dimension: 1200 mm x 2500 mm

| Value | Units | Test Method / Conditions | |

| Sandwich Thickness | 6 - 20 | mm | — |

| Skin Layer Thickness | 0.25 | mm | — |

| Core Thickness | 5.5 - 19.5 | mm | — |

| Cell Size | 4 - 5 | mm | — |

| Weight per Unit Area | 1170 - 2530 | g/m² | — |

| Sandwich Density | 195 - 210 | kg/m³ | — |

| Core Density | 80 - 90 | kg/m³ | — |

| Bending Stiffness (CD, L - MD, W, At 400 mm Span Length in 3PB Test) | 18 - 320 | Nm | — |

| Compressive Strength (Z-direction) | 1.2 | MPa | ASTM C365-57 |

| Compressive Modulus (Z-direction) | 25 - 40 | MPa | ASTM C365-57 |

| Shear Strength (CD, L - MD, W) | 0.3 - 0.5 | MPa | ASTM C273-61 |

| Shear Modulus (CD, L - MD, W) | 6 - 15 | MPa | ASTM C273-61 |

| Thermal Conductivity | 0.045 - 0.075 | W/m*K | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- ThermHex Organosandwich - The New Sandwich Material

The Organosandwich production is based on the patented ThermHex process. The process enables the continuous inline production of thermoplastic honeycomb cores in a fully automatic production line.

By using our lightweight Organosandwich weight savings of over 80 % are possible compared to a monolithic construction. In comparison to a monolithic organosheet laminate, a sandwich of the same stiffness requires less number of layers, which means considerable cost savings when using the Organosandwich.

The Organosandwich consists of glass fiber reinforced polypropylene face sheets (GF/PP). Cross ply (0 °/ 90 °) skin layers (CP) containing continuous glass fibers or skin layers with long fiber reinforcement (GC) can be applied. The folded honeycomb core material consists of a polypropylene as well. This allows an optimal bonding between core and skin layers in the lamination process by thermoplastic welding. The sandwich can be pressed locally to a monolithic laminate which allows the thermoforming of multi-curved shell structures and the pressing of pressure stable monolithic joining surfaces in one step. The pressed areas offer the possibility of functional integration by means of injection molding. Hence, complex lightweight parts can be produced very cost-efficient in short cycle-times which is essential for many automotive applications.