Knowde Enhanced TDS

Identification & Functionality

- Carrier

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Component

Mixture of high molecular weight block copolymers with pigment affinic groups and surfactants.

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Characteristics

- Good wetting effect to pigment and fillings

- Outstanding controlling flocculation effect

- Provide powerful charge repulsion property;

- Suitable for various powder;

- Reduce viscosity of grinding system, improve color development of millbase;

- Specially suitable for organic pigment dispersion;

- APEO free

Applications & Uses

- Markets

- Applications

- Ink & Toner Type

- Highly Recommended Applications

- Inorganic powder materials

- Carbon blacks

- Phthalocyanine pigments

- Alumina powder

- Recommended Applications

- Water-based inks

- Architectural coating

- Wood and furniture coatings

- Automotive coatings

- Can coatings

- Anticorrosive paint

- Leather coatings

- Operation Proposals

- Suggested dosage of inorganic pigment(Based on pigment, Toynol® dispersants calculate solid content SOP):8-15%.

- Suggested dosage of neutral color carbon black (Based on pigment, Toynol® dispersants calculate solid content SOP):50-100%;

- Do not add wetting agents separately;

- Toynol® wetting agents can accelerate original powder wetting;

- Adding Toynol® defoamers can quickly eliminate grinding foam;

- To obtain optimal performance, Toynol® additives must be added in water before resin and pigment;

- Advise gradient test;

Properties

- Physical Form

- Appearance

- Yellow Semi-Transparent Liquid

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Content | 35.0 | % | - |

| Defoamer | 0.1-0.3 | - | - |

| Dispersant Dosage (SOP) | 10.0 | % | - |

| Dispersion Fineness | max. 2.5 | μm | - |

| Millbase Viscosity | Excellent | - | - |

| pH (1% Aqueous Solution) | 8 - 9 | - | - |

| Pigment Content | 20.0 | - | - |

| Water | Add To 100% | - | - |

| Wetting Agent | 0-0.3 | - | - |

| Wetting Of Original Powder | Quick | - | - |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Grinding Operation

Dispersing sand mill;Glass bead(0.8-1.2mm):

Filling rate 70%

3000rmp/min 60min- Performance Evaluation

- Fineness measure:Scraper fineness meter;

- Shelf stability: Take a certain amount of Cerium oxide slurry into measuring cylinder with stopper, place 5 days at 40℃ constant temperature and observe layering of conductive black slurry after a period.

- Centrifugal stability: take 20ml millbase into centrifuge tube, centrifuge 10 min under condition of 3000r/min, then take out to observe the layering of millbase. Pour out liquid and calculate amount and percentage of precipitate.

- Viscosity evaluation:Use Brookfield rotational viscometer

- Viscosity stability:Store millbase in 100ml wild-mouth bottle at 40℃ for 24 hours, measure viscosity change, ±50% change is regarded qualified.

- Experimental Pigment

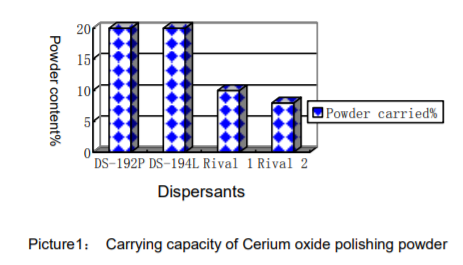

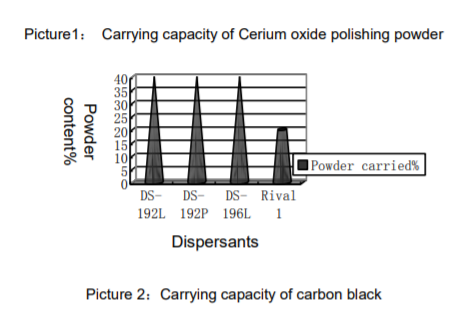

Cerium oxide polishing powder , powder content 20%

- Carrying Capacity

Packaging & Availability

- Packaging Type

- Packaging

- 25L/plastic drum

- 220L/iron drum

Storage & Handling

- Shelf Stability

- Excellent

- Storage

As liquid material, this product should be sealed and placedmin a dry, cool, well-ventilated place at room temperature away from fire source.