Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Product Families

- Chemical Component

Organic polymer

Features & Benefits

- Labeling Claims

- Characteristics

- Silicone and mineral oil free;

- Without hydrophobic particles;

- Good foam break effect;

- Lasting antifoaming effect;

- Without causing surface problems as pinhole and shrinkage;

- Specially suitable to eliminate difficult foam caused by anion matters;

- APEO free

Applications & Uses

- Applications

- Applicable Processes

- Fluids & Lubricants Type

- Coating Type

- Fluids & Lubricants End Use

- Industrial Additives End Use

- Recommended Applications

- Water-based coatings

- Printing chemicals

- Adhesives and sealants

- Emulsion polymerization

- Textile finishing

- Metal working fluids

- Water treatment

- Operation Proposals

- Add in each stage in production of water-based products;

- Do not dilute defoamers to avoid influencing defoaming property;

- If defoamer appears freezing or layering, it should be melted or mix even at first;

- After adding defoamer, it should be stirred completely to make sure good dispersion of defoamer;

- Suggested dosage is 0.2-1%;

- Advise gradient test;

Properties

- Physical Form

- Appearance

- Yellow To dark Yellow Liquid

- Sparingly soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Active Matter Content | 100.0 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Performance Evaluation

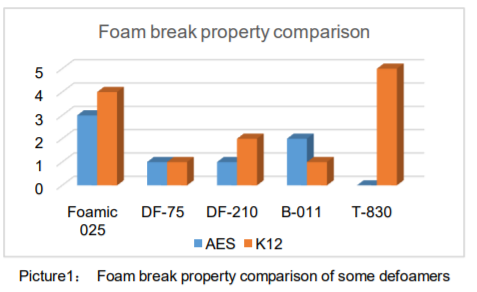

- Foam break experiment

- Take 100ml 0.1% foaming solution into 1000ml measuring cylinder,then open air pump to bubble to 1000ml and turn off air pump;

- Take 100 ul defoamer into measuring cylinder and record time of foam elimination.

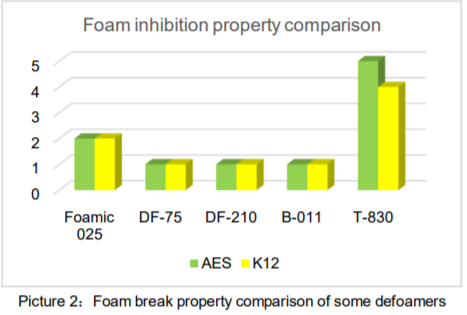

- Antifoaming experiment

- Operate as foam break experiment;

- After foam disappearing, bubble once more, record the time the foam increases up to 1000ml;

- Operate (2) repeatedly and take the average time.

Scoring standard of foam break: 5 point, <30s is 5 point; 30-60s is 4 point; 60-90s is 3 point;1.5-3 mins is 2 point; 3-5 minutes is 1 point; other time is 0 point;

Standard Score <30s 5 30-60s 4 60-90s 3 90-180s 2 180-300s 1 Other time 0 Scoring standard of foam inhibition: 5 point, >30 mins is 5 point; 10-30 mins is 4 point; 5-10 mins is 3 point;1-5 mins is 2 point;; < 1 min is 1 point;

Standard Score >1800s 5 600-1800s 4 300-600s 3 60-300s 2 <60s 1 - Foam break experiment

- Foaming Agent Preparation

Take 1g foaming agent into 1000ml breaker, then add water to dilute and prepare foaming agent solution with 1% active content; Stir10 min and then add water to dilute as 0.1% solution for reservation.

- Property Comparison

Packaging & Availability

- Packaging Type

- Packaging

- 25L/plastic drum

- 220L/iron drum

Storage & Handling

- Storage

As liquid material, this product should be sealed and placed in a dry, cool, well-ventilated place at room temperature away from fire source.