Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Identification & Functionality

Points To Note

- Top coating with a clear exterior grade powder coating over an interior grade powder coating does not result into a weather resistant coating system.

- Post-bending properties of any part must be verified prior to application. Minor cracks in the coated surface may lead to corrosion.

- Joint sealants and any other auxiliary products, such as glazing aids, gliding waxes, drilling and cutting lubricants, which come in contact with the coated surface, must be pH-neutral and free of substances that may damage the finish. Therefore, a suitability test at the applicator’s end, prior to coating, is highly recommended.

- In general, colors in the red, orange and yellow range may require an increased film thickness to achieve full hiding.

- Any post-mechanical processing of already coated parts, such as sawing, drilling, milling, cutting and bending will result in damage of the coated surface and will subsequently weaken the corrosion protection.

Chemical resistance

The required chemical resistance of a powder coating depends, among other things, on its formulation. Chemical resistance requirements must be considered according to processing conditions and final use of the finished product. This is best established during the product specification process. Agreement between all parties involved must be reached about the requirements for such chemical resistance as well as the test method, which may be performed in accordance with PCI test method “Solvent Cure Test”. Furthermore, the test duration and concentration of the test media need to be agreed upon.

Features & Benefits

- Ready-to-Use Product Features

- Features

- excellent weather resistance

- excellent UV-light resistance

- AAMA 2604* compliant

- 5 years South Florida exposure

- very smooth flow

- good storage stability

- good yellowing stability

* AAMA 2604 compliance dependent upon the color and/or effect

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Applications & Uses

Typical Applications

- metal facades

- steel constructions

- stadium seating and railings

- residential windows and doors

- patio furniture and garden equipment

- railings

- playground equipment

- agriculture equipment

- external ship components, communication towers, doors and railings

- military camouflage

Special Applications

Objects directly exposed to salt/fog conditions in a marine environment or need heavy corrosion protection must be coated with TIGER Shield system.

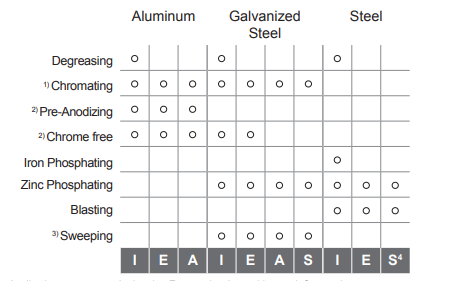

Pretreatment

The following table reflects the common methods of pre-treatment with regards to various substrates and applications. In selecting the proper type of pretreatment, the suitability of the type of powder coating for a desired application according to the guidelines on this page should be observed.

I = interior; E = exterior; A = architectural; S = steel

Application

- According to ASTM B 449.

- According to GSB quality and test regulations. The suitability of this type of pretreatment needs to be established through a boiling water test and subsequent cross-hatch adhesion and adhesive tape removal test.

- Only for zinc coated parts >45 μm (>1.8 mils) 4) for a two-coat process/TIGER Shield.

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 1.2 - 1.8 | g/cm³ | ASTM D792 |

| Theoretical Coverage (60 µm Film Thickness) | 9.8 | m²/kg | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Data

Test results

Checked under laboratory conditions on 0.7 mm (1/64 inch) thick yellow chromated aluminum test panel. Actual product performance may vary due to product-specific properties such as gloss, color, effect and finish as well as application-related and environmental influences. When used as a two-coat system, the increase in film thickness will result in a decrease of mechanical properties.

Test Method Test Series 38 Smooth Glossy

ISO 2360 Recommended film thickness 60-80 um (2.5 - 3.5 mils)

ASTM D523 Gloss-60 80 - 95+ ASTM D3359 method B Cross cut tape test 1mm cutting distance 5B ASTM D522 Mandrel bending test cracking of coating 3 mm ASTM D2794 Ball impact test cracking of coating up to 40 in.lb., cracking at the perimeter of the concave area but no cracking pick off

ASTM D3363 Pencil hardness 2H minimum ASTM D2247 Determination of resistance to humidity 3,000 hours maximum undercutting 1 mm (1/32 inch)

ASTM B117 5% salt spray solution 3,000 hours maximum undercutting 1 mm (1/32 inch)

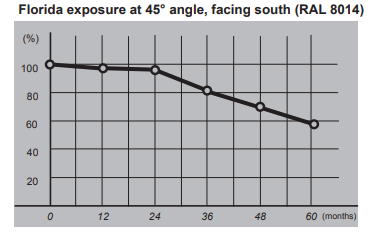

ASTM D2244 Natural weathering in Florida 5 years color change max. 5.0 (Hunter)

ASTM D523 Natural weathering in Florida 5 years gloss retention min. 30%

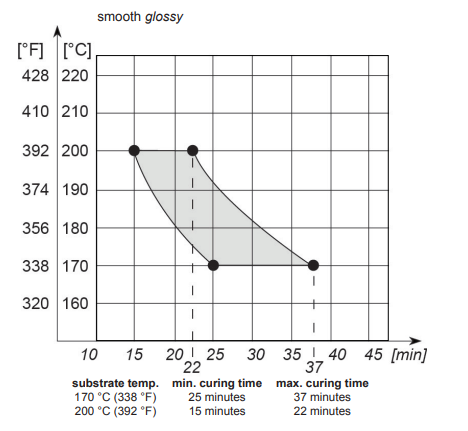

Cure parameters (substrate temperature versus curing time)

Cure parameters must be closely observed since mechanical properties will develop before full cross-linking.

Weather resistance

Remaining gloss versus months: The remaining gloss values that can be expected may vary depending on the original gloss level and color. A reasonable degree of gloss loss and color variation owing to long term UV exposure should be expected.

Finish

Finish Gloss smooth glossy 80 - 95+* smooth semi-gloss 60+/-5* smooth matte 20+/-5* - * Gloss level according to ASTM 523 at 60° angle (doesn‘t apply to metallic effect powder coatings). The measured gloss level of effect powder coatings can diverge from the details given in this Product Data Sheet. The creation of tolerance samples is recommended.

- Available as stock-product in smooth glossy, semi-gloss and matte in 70 colors. It can be custom-matched in limited colors (minimum order quantity and color limitation apply).

Packaging & Availability

- Packaging Type

- Standard Packaging

In original 20 kg (44 lb) box and 2.5 kg (5 lb) minipack.

Storage & Handling

- Storage Stability

12 months at no more than 25°C (77°F) avoid direct and extended exposure to heat.