Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Technologies

- Product Families

- Elements

Glass fibers, functional fillers and NBR (Nitrile Butadiene Rubber)

Features & Benefits

- Labeling Claims

- Materials Features

- Features

- Ideal for use in medium to high temperatures and pressures

- Outstanding mechanical strength

- Leakage less than limits specified in DIN 3535-6

- Exceptionally good resistance to steam and fluids such as oils, fuels and hydrocarbons WRAS approved for use in hot and cold potable water

- Anti-stick coating on one side • Approvals: BS7531, DVGW, KTW*, BAM*, TA Luft, WRAS*, EC 1935/2004

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

- Aircraft gear boxes, pumps, hydraulic systems and actuators

- Instrumentation

- Pumps, valves, compressors, drives and engines

- Gas and water supply including heating (sanitary engineering)

- Pipeline construction

- Plant construction and maintenance

- Machine manufacturing

- Typical Healthcare & Medical Applications

Wheelchair hub bearings, actuators, valve seats, reciprocating and oscillating applications.

Properties

- Color

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.8 | g/cm3 | DIN 28 090-2 |

| Tensile strength (longitudinal) | 21 | N/mm2 | — |

| Tensile strength (transverse) | 9 | N/mm2 | — |

| Residual stress (σdE/16, 175°C) | 38 | N/mm2 | DIN 52 913 |

| Residual stress (σdE/16, 300°C) | 28 | N/mm2 | DIN 52 913 |

| Compressibility | 7 | % | ASTM F 36 J |

| Recovery | 62 | % | ASTM F 36 J |

| Cold Compressibility (εKSW) | 5.5 | % | DIN 28 090-2 |

| Cold Recovery (εKRW) | 3 | % | DIN 28 090-2 |

| Hot Creep (εWSW/200) | 12 | % | DIN 28 090-2 |

| Hot Recovery (εWRW/200) | 15 | % | DIN 28 090-2 |

| Specific Leakage Rate | max. 0.100 | mg/(s·m) | DIN 3535-6 |

| Weight Change (5h/150°C) | 7 | % | ASTM IRM 903 |

| Thickness Increase (5h/150°C) | 2 | % | ASTM IRM 903 |

| Weight Change (5h/23°C) | 9 | % | ASTM Fuel B |

| Thickness Increase (5h/23°C) | 4 | % | ASTM Fuel B |

| Leachable Chloride content | max. 150 | ppm | FZT PV-001- 1330 |

Regulatory & Compliance

- Certifications & Compliance

- Good for People and the Environment

HiMod® FlatSeal 15 is manufactured in facilities that comply with ISO/TS 16949 and ISO 14001. This means complete transparency in all areas of production and a high degree of security for our customers.

- Approvals

BS7531, DVGW, KTW*, BAM*, TA Luft, WRAS*, EC 1935/2004

Technical Details & Test Data

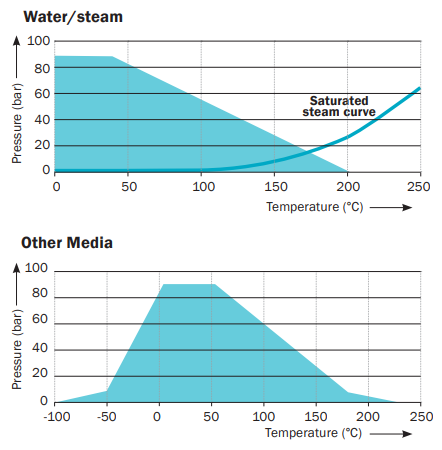

- Recommendations for Use (according to pressure and temperature)

The temperature and pressure recommendations in the graphs apply to gaskets with a thickness of 2.0 mm and smooth flanges. Higher stresses are possible when thinner gaskets are used. Example for the most commonly used other media. Exact data for specific, individual cases are available on demand.

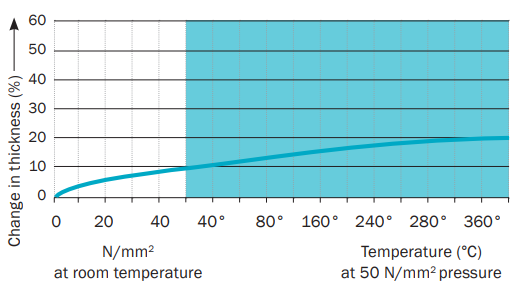

- Deformation under temperature 2.0 mm

Packaging & Availability

- Products Available

Bearings, Flatseal™, Slydring®, Wear Rings, Back-up Rings, Custom Shapes.

- 10

Thickness in mm 0.5/ 1.0/ 1.5/ 3.0 Further thicknesses are available on request

Thickness tolerance According to DIN 28 091-1