Knowde Enhanced TDS

Identification & Functionality

- Vehicle Type

- Acrylic

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

- Excellent adhesion to bare steel and aluminum.

- Single component water-based primer.

- Fast dry technology.

- Prevents corrosion.

- Exceptionally easy component primer.

- Chemical and UV resistant.

- Use under non-sumbserisble and submersible Tuff Coat.

Applications & Uses

- Markets

- Product Application

- Stir thoroughly before use.

- Tuff Coat may be applied by Tuff Coat roller or spray.

- Applying excessively heavy films will lead to insufficient through-drying and mud cracking of the paint and will yield soft paint films.

- Do not apply Tuff Coat on extremely humid days 75% RH or when rain is threatening.

- Do not apply in the late afternoon when working outdoors as the wet film may be adversely affected by dew.

- When working in cooler temperatures be sure the air and surface temperatures will remain at or above 45°F for at least 8 hours after application and the surface temperature will remain 5°F above the dew point during the application.

- Surface Preparation

- Coating performance, in general, is proportional to the degree of surface preparation.

- Follow recommendations carefully, avoiding shortcuts.

- Inadequate preparation of surfaces will virtually assure inadequate coating performance.

- Surface must be free of dirt, loose paint, rust, oil, grease, wax, soap and any other foreign matter.

- Prep painted areas well.

- Remove existing mildew with household bleach instead of ammonia.

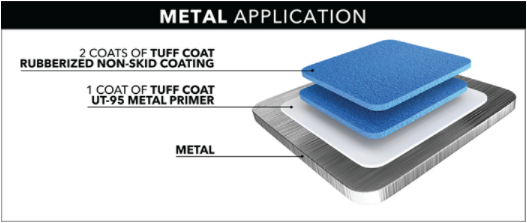

- Product Application - Metals

- Sand surface with 80 grit sandpaper, then solvent clean with thinner to remove residue.

- Apply a coat of Tuff Coat UT-95 Metal Primer following overcoat instructions, apply 2 coats of Tuff Coat.

- Mixing

- Due to the high solid’s nature of this product, there will be significant settling that occurs in the can or pail.

- Stir or shake contents thoroughly to remix any settled material.

- While applying the product, make sure to mix the product remaining in the can or pail often to ensure proper suspension of the non-skid additive into the paint film.

- Product Application

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Components | 1.0 | — | — |

| Solids (Weight) | 58.0 | % | — |

| Solids (Volume) | 48.0 | % | — |

| Coverage (2 Coats) | 200.0 | ft²/gal | — |

| VOC | 35.0 | g/L | — |

| Flash Point | 200.0 | °F | — |

| Thinner | Do Not Thin | — | — |

| Maximum Roller Thickness | 0.375 | inch | — |

| Number Of Coats | 1.0 | — | — |

| Wet Film Thickness Per Coat | 6.0 | mils | — |

| Dry Film Thickness Per Coat | 4.0 | mils | — |

| Application Temperature | 45 - 95 | °F | — |

| Dry Time (90°F) | 30.0 | min | — |

| Dry Time (70°F) | min. 1 | hours | — |

| Dry Time (50°F) | min. 2 | hours | — |

| Dry Time (90°F, Recoat) | min. 1 | hours | — |

| Dry Time (70°F, Recoat) | min. 1.0 - 2.0 | hours | — |

| Dry Time (50°F, Recoat) | min. 2.0 - 4.0 | hours | — |

| Dry Time (90°F, Max Recoat) | min. 24 | hours | — |

| Dry Time (70°F, Max Recoat) | min. 48 | hours | — |

| Dry Time (50°F, Max Recoat) | min. 96 | hours | — |

Packaging & Availability

- Availability

Availbale in quarts and gallons.