Knowde Enhanced TDS

Identification & Functionality

- Flavor

- Flavor Family

- Ingredient Name

- Ingredient Origin

- Food Ingredients Functions

- Ingredients

- Barley Malt

- Technologies

Features & Benefits

- Food Ingredients Features

- Grain History

This malt was made from Copeland two-row barley that was grown by Stober Farms. Stober Farms is a 5th generation family farm located near Goodrich, ND and has been producing the highest quality grains for over 100 years.

Two Track Malting uses grain grown without irrigation by producers practicing regenerative agriculture. This results in the highest quality grain with the least environmental impact.

Applications & Uses

- Markets

- Applications

Properties

- Malt Analysis

| Value | Units | Test Method / Conditions | |

| Fine Grind - Coarse Grind, Dry Basis | 11.4 | % | — |

| pH Value | 5.6 | — | — |

| Clarity | Hazy | — | — |

| Coarse Grind, Dry Basis | 67.6 | % | — |

| Color | 11.4 | °SRM | — |

| Diastatic Power | 43 | °L | — |

| Filtration | Normal | time | — |

| Fine Grind, Dry Basis | 79 | % | — |

| Free Amino Nitrogen Content | 102 | mg/L | — |

| Friability | 61 | % | — |

| Moisture Content | 4.2 | % | — |

| S/T | 33.7 | % | — |

| Soluble Protein Content | 3.81 | % | — |

| Total Protein Content | 11.3 | % | — |

| α-amylase Content | 25.9 | D.U. | — |

| β-glucan Content | 741 | mg/L | — |

Technical Details & Test Data

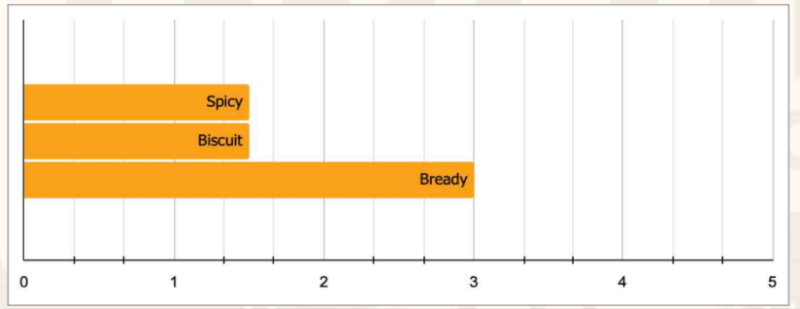

- Malt Sensory Profile

- Technical Information

Hot Steep Method

Items needed to perform the Hot Steep Method:

- Malt to be tested

- 24-ounce Thermos

- Funnel

- Cone coffee filter

- Coffee grinder

- Scale capable of weighing 50.0 g (± 0.1 g)

- Glass beaker, tall, 600 mL volume

- Thermometer, standard, 0-200°C

- Quart sized large or small mouth canning jars

- Heating apparatus, capable of heating water to 65°C

1. Grind 50 g. of malt in coffee grinder (grind for 10-15 seconds)

2. Add 400 ml of 65°C (149°F) water to Thermos

3. Add malt grist to water, cap thermos and shake for 20 seconds

4. Let rest for 15minutes

5. When timer is up, swirl for a few seconds then pour into filter

in funnel over large jar

6. Collect 100ml of wort and add it back into filter

7. Collect and tasteCheck Your Malt Grind

Take 100g of milled malt grist and place in a #14 sieve stacked over a #30 sieve over a #60 sieve over a pan. Slide 18" back and forth on a smooth surface for 3 minutes, stopping to tap stacked sieves sharply on surface every minute. Record Grist

retained in each sieve. Chart below gives percentage of what should be retained in each sieve for each grind.100 gram sample #14 sieve #30 sieve #60 sieve Pan Coarse grind 78 grams 14 grams 4 grams 4 grams Medium grind 53 grams 28 grams 11 grams 8 grams Fine grind 25 grams 25 grams 30 grams 20 grams Calculating PPG and OG

PPG (Specific gravity of 1 lb of fermentable in 1 gal of water) / PPG=46.214 x (DBCG/100-MC%/100-0.002)

Original Gravity Calculation / OG=1+(EF%/100) x (PPG x MW/BV)

MW = Malt weight in pounds

BV = Batch volume in gallons

EF% = Mashing efficiency

OG = Original gravity

PPG = Pounds per gallon

MC = Moisture content

DBCG = Dry basis coarse grind extract