Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

- Ingredients

Ingredients are 100% natural, nonhazardous, nontoxic and biodegradable

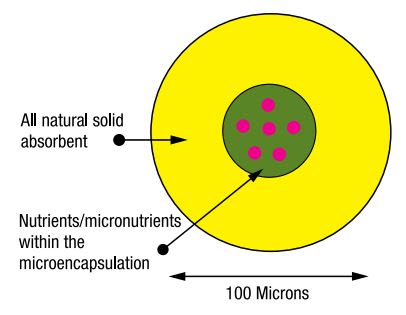

Naturally Occuring microorganisms Nutrients and micronutrients which are required for metabolic activity of microorganisms

Features & Benefits

- Labeling Claims

- Product Highlights

Methods of applying PRP® range from a simple hand sprinkle to portable, mechanized hydro seeders.

PRP® consists of tiny spheres of treated wax, which contain nutrients. When a wax sphere comes in contact with spilled oil, it “binds” with the hydrocarbons. Nutrients in the sphere help microorganisms from the immediate environment flourish until they eat every droplet of oil. PRP® will absorb and remediate, over time, more than 20 times its weight.

Petroleum Remediation Product (PRP®) can be used for various oil, fuel and other liquid petroleum hydrocarbon cleanup applications such as fuel or oil spilled on land or ground, oil spills on shorelines, waterways or marinas, hydraulic fluid spilled in industrial plants, vehicle leaks, gasoline or fuels flowing into stormwater runoff, heating oil in home storage tanks, railroad ballasts, oil wells & oil fields, transformer vaults, maintenance facilities, vehicle rollovers, marsh and wetlands, car wash or parking garage washing usage or areas where oil, diesel fuel, gasoline, liquid petroleum or other hydrocarbon cleanup and natural bioremediation requirements.

Applications & Uses

- Markets

- Applications

- Application Area

- Directions for use

- Bulk : apply dry , bynd or dispense by agitation in water using a hydroseeder fire cannon or other venturi apparatus. An application ratio of 1:2 by weight of PRP to oil is recommended for control and containment of the spill

- Bio-sok: after removing the sok from the plastic bag, tie it securely with the cord provided to a fixture in the bilge of the boat. Be certain to place the sok where it will not get caught up in moveable parts. Then drop it into the water in the bilge tank where it will float, absorbing and biodegrading the leaking Oil/fuel.

- Bio-boom: remove plastic sleeve, position bio boom, and tie securely with the cords on each end. Do not stretch tightly. Leave Some slack. Should the area exceed the length of a single bio boom, link as follows: lay the bio boom end to end, Overlapping so that the end of each boom is adjacent to the loop of the other boom (8" from end). Draw cord around Opposite boom and tie to loop. Attach both overlapping ends. Biobooms must fit together snugly. Avoid indenting boom With cord.

Properties

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- PRP Hydrocarbon Spill Response Product

PRP can be applied to most tracts of land and clings to most surfaces. It is effective in fresh

and salt water to control the spreading of oil spills in a one step application. It significantly

enhances the biodegradation of the spill. The product then ultimately biodegrades itself.

- Hydrophobic and oleophilic

- Nontoxic and nonhazardous

- Stimulates indigenous microorganisms

- Bioaugments the degradation of the spill

- Minimizes volatilization

- NCP product schedule listed*

Because it will not sink and repels water even after oil absorption, the benefits of PRP®

application are significant:- ORapid clean-up is facilitated.

- Hard to reach areas such as sensitive marshlands can be treated remotely. If left in place, the PRP and oil will biodegrade, minimizing any toxic effects of the oil.

- PRP reduces potential for the coating of mammals, wildlife, and plants which typically results in severe damage.

- Damage to beaches is minimized because the contamination is prevented from getting below the surface.

- If removal of the PRP/oil matrix is preferred, total recovered volumes are minimal, unlike vacuum

- systems which generate large volumes of contaminated water and minimal amounts of oil. The recovered matrix can then be landformed and bioremediated.

Apply PRP on transfer areas, marshlands, drainage ditches, wetlands, holding ponds, lagoons, shores, marinas, and harbors. Reduce disposal costs of oil contaminated water at industrial sites or spill clean-up operations by Using PRP to separate the oil from the water.

- Control spill

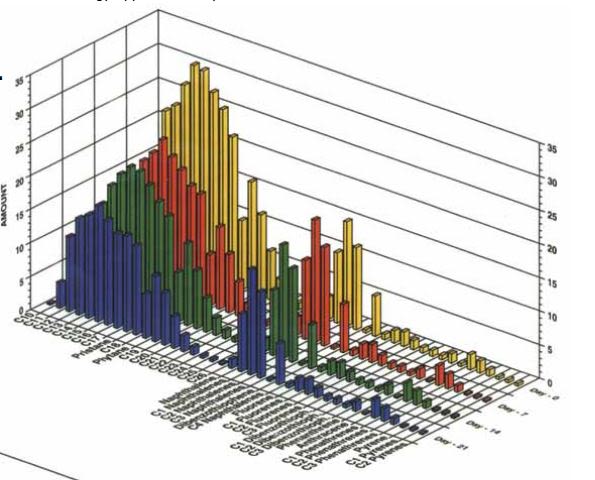

- These charts represent data from PRP® diesel fuel spill field test overseen and evaluated by National Environmental Technology Application Corporation (NETAC).

- No biodegradation

- Loss due to volatilization only

- Test Data

PRPs® initial efficacy was quantified under simulated field conditions. This efficacy study was conducted by an independent environmental technology evaluation organization known as the National Environmental Technology Applications Corporation (NETAC). NETAC was key in the development of methods currently used by the U.S. EPA to evaluate biological methods that enhance oil spill degradation. There are five key findings of the study:

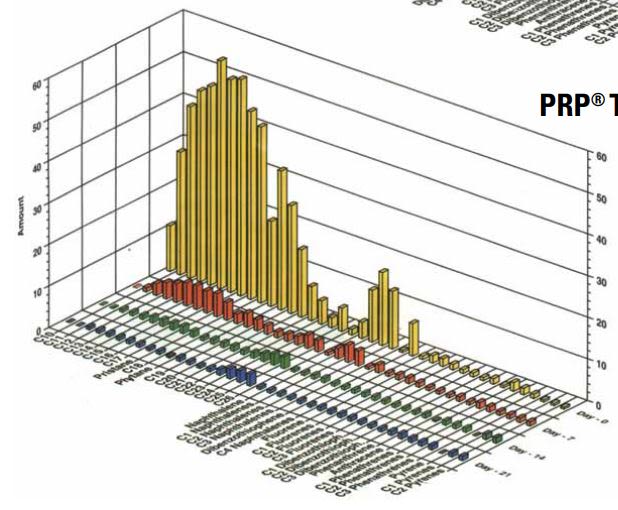

- PRP® Powder enhances the biodegrading of diesel fuel as compared to non-stimulated natural population of micro organisms.

- PRP® Powder treatment reduced the presence of aliphatic hydrocarbon compounds by 97% and aromatic compounds by 76%; reduction in the control product were 48% of aliphatic compounds and 5% of aromatic compounds.

- PRP® Powder interacts with diesel fuel oil to form a matrix, producing a mixture which is solid and relatively stable.

- No enhancement in biodegradation was found in the control group of sorbents.

- PRP® Powder used in conjunction with an absorbent and a boom, absorbs petroleum products and enhances the biodegradation of diesel fuel oil by absorption into the sorbent boom.

PRP® is now in use in multiple remediation scenarios across a wide spectrum of industries.

- PRP treated spill

- These charts represent data from PRP® diesel fuel spill field test overseen and evaluated by National Environmental Technology Application Corporation (NETAC).

- Within three weeks:

- 97% decrease in aliphatics

- 76% decrease in aromatics

Packaging & Availability

- Packaging Type

- PRP specifications

BULK 50 lb. drums BIO-SOK 8 oz. per SOK BI0-BOOM® 12 0z. per ft. Do Not use this product with any other bilge cleaners or detergents as they prevent the oil/fuel from being absorbed