Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Advantages

- Certified by ICC-ES (ESR-3573)

- Meets ACI 440.2r-08 criteria

- May be utilized to enhance shear, confinement or flexural strength

- Can accommodate complex 3-D shapes

- High strength to weight ratio

- Light weight, adds negligible dead load to structure

- Non-corrosive and non-magnetic

- Acid and alkali resistant

- Finished application does not change the esthetics of the structure

Applications & Uses

- Markets

- Applications

- Composites End Use

- Applications

Structural capacity changes

- Increased live or dead loads in structures

- Increased traffic volumes on bridges and viaducts

- Dampen vibrating structures or change the natural frequency

- Accommodate changes of building utilization or industrial machinery layout

- Allow for the removal of walls, columns or sections of floor slabs

Seismic retrofitting

- Upgrade of reinforced concrete columns

- Retrofit of unreinforced masonry walls

- Increase lateral shear resistance in reinforced masonry walls

Blast resistant upgrades

- Column protection

- Masonry wall protection

Structural damage and repair

- Repair of large diameter pipes to achieve strengthening and water-proofing

- Repair of aging or corroded members

- Repair or upgrade of inferior materials

- Repair of inadequate construction techniques

- Repair of members due to fire or natural disaster

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Ultimate Tensile Strength Primary Fiber Direction (Ultimate Value, Design Value) | 1,414 (1,245) | Mpa | — |

| Tensile Modulus (Ultimate Value, Design Value) | 116,170 (116,170) | Mpa | — |

| Elongation at Break (Ultimate Value, Design Value) | 1.22 (1.07) | % (Mpa) | — |

| Flexural Strength (Ultimate Value, Design Value) | 814 (690) | Mpa | — |

| Compressive Strength (Ultimate Value, Design Value) | 499 (424) | Mpa | — |

| Value | Units | Test Method / Conditions | |

| Short Beam Shear (Ultimate Value, Design Value) | 45 (38) | Mpa | — |

| Glass Transition Temperature (Ultimate Value, Design Value) | 71.5 (71.5) | Mpa (°C) | — |

| Laminate Thickness (Ultimate Value, Design Value) | 0.850 (0.850) | Mpa (mm) | — |

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion (Ultimate Value, Design Value) | 50.07 (50.07) | Mpa (μm/m/°C) | — |

Technical Details & Test Data

- Limitations

The installed system acts as a vapor barrier. Concrete should not be fully encapsulated in areas of freeze/thaw.

- Competitive Testing and Additional Physical Testing

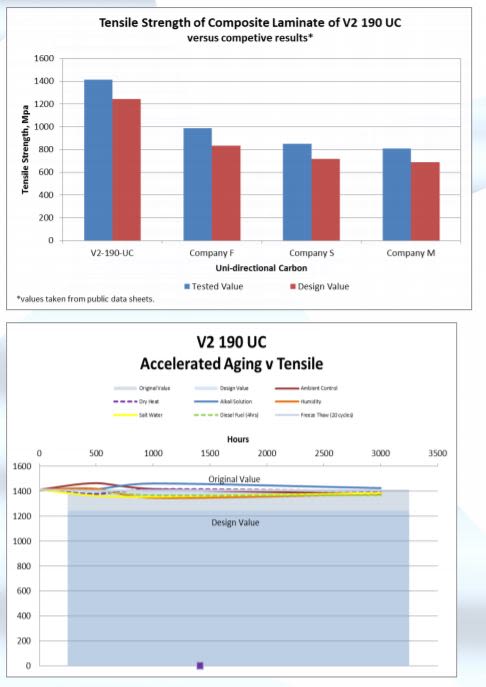

Competitive Testing - V2 Structural Systems takes its performance values very seriously and commits to its unique performance in each properly installed application. The following chart compares commercially available data with performance values (both typical and design) for StructureWrap V2 190 UC versus commonly available carbon reinforcement systems. Note that the StructureWrap V2 190 UC Design and Typical values exceed the standard values of all competitive products in the industry.

Accelerated Aging – V2 Structural Systems is aware of the rigorous and abusive environments that it’s products are expected to perform in. Every environment can not be specifically tested but V2tests each of it’s systems in the harshest environments available in laboratory conditions. V2 also extends its aging process well beyond the required limits of performance. The chart below describes the change in tensile stress upon aging for the described hours in the specified conditions. Note that even after 3,000 hours in the cruelest environments that the V2 strengthening system does not even draw near to the Design Value that we stand behind.

Safety & Health

- Packaging

Rolls: 25 in. x 50 ft. (104 ft.2); 25 in. x 300 ft. (625 ft.2); Custom widths of 6”-50” are available

Kits: Pre-measured kits containing a 25 in. x 50 ft. (104 ft.2) roll of fabric and 3 gallons of StructureWrap V2 200 Epoxy

- Caution

StructureWrap V2 190 UC is non-reactive and non-toxic. However, caution must be used when handling since stray fibers and dust may be present on the surface. Gloves and the use of an appropriate properly fitted NIOSH approved respirator is recommended to prevent skin and lung irritation when handling, cutting and applying StructureWrap V2 190 UC.