Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Agrochemical Functions

- Technologies

Features & Benefits

- Agrochemicals Features

- Product Info

- ProTone can be used to initiate earlier harvest, increase overall marketable yield, and/or reduce the number of picks within a particular block. It can be applied from the time of veraison to late in the season. The optimal timing for a particular block will depend on the cultivar and the harvest management objective. While most early season applications of ProTone are effective in developing marketable color, late season applications are also very effective in most cultivars, even after sugar development has occurred.

- ProTone works well with ethephon in an integrated coloring program. Ethephon will increase ethylene gas production, spurring ripening, while ProTone will trigger coloring only. Note that ProTone does not translocate throughout the fruit; for optimal product efficacy ProTone needs to be applied directly to the fruiting cluster and complete coverage of berries is essential.

- With ProTone, growers can accelerate and better manage their harvest to peak at times when prices are high for premium grapes. Red table grapes can be colored earlier and more evenly for greater packout and more flexible yield without compromising pre- or postharvest quality.

- Product Background

The active ingredient in ProTone® is S-abscisic acid, or more commonly denoted as S-ABA, a naturally occurring plant growth regulator produced by plants and commonly found in fruits and vegetables (Cutler and Krochko, 1999; Finkelstein, 2002; Schwartz and Zeevaart, 2004). Abscisic acid is typically found as a racemic mixture of both the active isomer S-ABA and the much less active isomer R-ABA. Through a proprietary manufacturing process ProTone® has been developed using only the pure, highly active S-ABA form of abscisic acid. Under optimal environmental conditions grapes produce sufficient S-abscisic acid so color development occurs rapidly and with adequate pigment to produce red grapes of significant commercial value. Unfortunately, environmental conditions in many growing regions are not always optimal for good color development. During these periods of suboptimal coloring pigment levels in fruit may not be sufficient to meet commercial standards resulting in significant financial losses. When such conditions exist, ProTone® can be used to supplement naturally occurring S-abscisic acid resulting in faster, more complete coloring and better yields of high quality red grapes. In red grape varieties, S-ABA is responsible for the development of pigments within the fruit skin that give them their distinctive color (e.g. Han et al., 1996; Lee et al., 1997; Kondo et al., 1998; Peppi et al., 2006; Peppi et al,. 2007). S-ABA enhances color development in mature berries by stimulating the production of an enzyme known as UDP-glucoseflavonoid 3-O-glucosyltrans ferase (UFGT; Boss et al., 1996a and 1996b). This enzyme speeds up the conversion of anthocyanidins into red pigments known as anthocyanins that give red grapes their color. Levels of S-ABA in plants range from a few parts per billion in some aquatic plants to 10 parts per million in avocado fruit (Milborrow, 1984). S-ABA is involved in many major processes during plant growth and development including dormancy, germination, bud break, flowering, fruit set, general growth and development, stress tolerance, ripening, maturation, organ abscission, and senescence. S-ABA also plays an important role in plant adaptation to environmental stresses such as drought, cold, and excessive salinity.

Applications & Uses

- Markets

- Applications

- Applicable Crop

- Formulations

- ProTone SG is a 20% soluble granule formulation

- ProTone SL is a 10% liquid formulation.

- Application Considerations for Using ProTone®

The general use guidelines presented here are the result of several years of extensive research, development and semi-commercial programs conducted by Valent BioSciences Corporation. Studies with ProTone® for grape coloring were conducted in conjunction with regional university and industry experts in the US, Chile, Australia, South Africa and other table grape producing countries. These guidelines represent “best practices” for using ProTone® on ‘Flame Seedless’, ‘Crimson Seedless’ and ‘Red Globe’ cultivars. Use of rates, application timings, or spray volumes outside of these recommendations or on other cultivars may result in inconsistent and/or less than desired product performance. This guide should be used only to supplement information found on regional product labels and not as a replacement for these labels. Always read and follow all regional label directions and precautions before using ProTone®.

Block Preparation : The use of ProTone® is part of a good coloring program. Blocks to be treated with ProTone® should be of high quality and managed to maximize color development at the time of application. For optimal product efficacy ProTone® needs to be applied directly to the fruiting cluster; complete coverage of berries is essential. Removal of foliage from both the front and the back of the cluster prior to application improves spray coverage and increases light penetration.

- Application Timing

- ProTone® improves berry color over a broad application window. In most regions, applications can be made from the beginning of veraison to late in the season, even after marketable sugar has developed. Veraison is defined as the initial stage of grape ripening and is marked by changes in color and/or softening of the berry. Specific indications of veraison vary from region to region.

- While specific timing recommendations for ProTone® vary based on cultivar, regional climate, orchard history and harvest management objectives, typically the first application is made near veraison. For example, short season varieties such as ‘Flame Seedless’ often benefit from applications made just prior to or at veraison while long season varieties such as ‘Crimson Seedless’ benefit from applications starting one to two weeks after veraison.

- Always apply when conditions favor slow drying for maximum absorption. Low wind speed, moderate relative humidity and moderate air and fruit temperature all favor slow drying. Apply in early morning or at night if daytime temperatures are over 85° F (30° C) or other daytime conditions are not conducive to slow drying.

- Depending on market conditions, cultivar, as well as expected weather patterns, multiple applications can be made at one to three week intervals. Multiple applications allow for a progressive increase in berry color and enable the spray program to be adjusted in response to environmental factors that either favor or delay color development. Strong market demand or the threat of late season rains may provide reason to employ a more aggressive coloring program to accelerate coloring.

- In most table grape growing regions residue limits and a PHI (pre-harvest interval) do not apply to ProTone®. Applications made after an initial harvest can enhance the color development of later harvests, even after marketable sugars have developed. When assessing the crop for repeat applications consider the proportion of marketable clusters showing green color. If a significant proportion of the remaining fruit are lacking marketable color, additional applications should be considered. Fruit may require up to three additional weeks for harvestable color to develop. Therefore, fruit must have acceptable berry firmness at the time of application with the potential to remain firm until harvest.

- Sprayer Set-up and Calibration

Sprayer set-up and calibration is essential for getting the best performance from ProTone®. Valent BioSciences Corporation has worked for several years on sprayer configurations and calibration to optimize ProTone® applications. These studies have evaluated several types of sprayers in various vineyard training systems in the US, Chile, South Africa, and Australia. In addition, an extensive two-year program was undertaken in conjunction with specialists in agricultural spraying from the University of Queensland (Australia) Center for Pesticide Application and Safety to determine the optimal spray methods for ProTone®.

These research studies show optimum

ProTone® efficacy is achieved with the following high volume spray equipment guidelines:- High water volumes are better than low water volumes.

- Low tractor speeds are better than high tractor speeds.

- High air volumes are better than low air volumes.

- Using low-flow nozzles and increasing the number of nozzles improves coverage.

- Adjust nozzle positions and airflow direction to target the clusters on the near side of the cordon and through the canopy to the backside of the clusters on the opposite side of the cordon.

Low volume, electrostatic sprayers have also been shown to be effective for ProTone® application. Environmental conditions at the time of application are especially important for good response to ProTone® applications with a low-volume sprayer. Only apply when conditions are favorable for slow drying

- ProTone® Rates

Color response to ProTone® application increases with increased dose rate. In most cultivars only one spray application per season is sufficient. In general, 150 grams active ingredient per acre (approximately 400 grams active ingredient per hectare) is the standard recommendation. If additional color is required, multiple applications can be made at one to three week intervals at a rate of 75 to 150 grams active ingredient per acre (200 to 400 grams active ingredient per hectare)

- Application Water Volume

After application rate, thorough and complete coverage of the clusters with spray solution is the single most important factor in establishing good performance with ProTone®. Using high volume spray equipment, spray volumes of 80 to 150 gallons per acre (750 to 1400 liters per hectare) have been shown to be effective, although with some trellis systems higher application volumes are needed. When using low-volume electrostatic sprayers coverage is equally important. Always be sure units are functioning properly and checked often during application. Uniform coverage throughout the front and back of clusters is essential as ProTone® does not effectively translocate from the leaves or even within the cluster. Coverage on the backside of clusters can be especially difficult in blocks with trellis training systems that have not been opened up with shoot and leaf thinning. With electrostatic equipment application volumes of 10 to 18 gallons per acre (90 to 170 liters per hectare) have been shown to be effective. Check with your local Valent BioSciences representative for recommendations for your area.

- Uses

Spray Tank Solutions : Always use clean filtered water with a final pH between 4.0 to 9.0 when preparing spray solutions containing ProTone®. Use of a nonionic surfactant has shown to increase spray coverage and aid in the uptake of ProTone®. Tank mixing ProTone® with agrochemical products other than those listed on the product use label have not been thoroughly investigated and are not recommended. Always make a new use solution of ProTone® each day.

Use with Ethephon : ProTone® is very effective as the sole coloring agent in a coloring program but can also be used in programs that include ethephon. The modes of action of ProTone® and ethephon are very different. Ethephon is an ethylene-releasing compound that can be translocated in the plant. ProTone®, by contrast, contains S-ABA and is a contact material. ProTone® applications should be made as if the product were being “painted” onto the fruit. Due to their unique modes of action, these two products can be used in a combined program with positive results.

Technical Details & Test Data

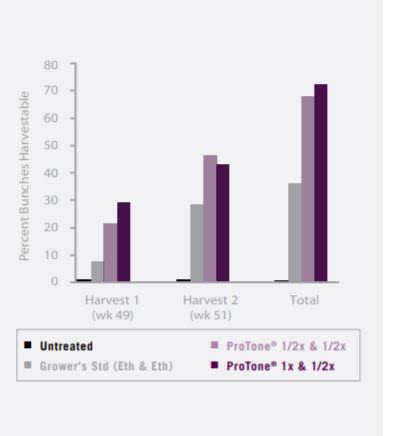

- More Harvestable Bunches ‘Crimson Seedless’, Aconcagua Valley, Chile

In the Aconcagua Valley of Chile, coloring of Crimson Seedless table grapes can be challenging. Use of ProToneTM can significantly increase the number of harvestable bunches, as is shown in this example. Even after sugar development has begun ProTone® can be applied to good quality grapes and produce marketable color. ProTone® is also exempt from the requirement to have a tolerance, making it ideal for grapes destined for export markets.

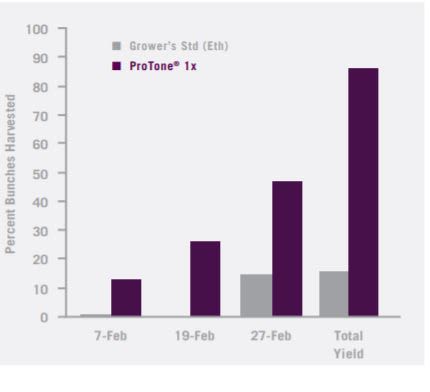

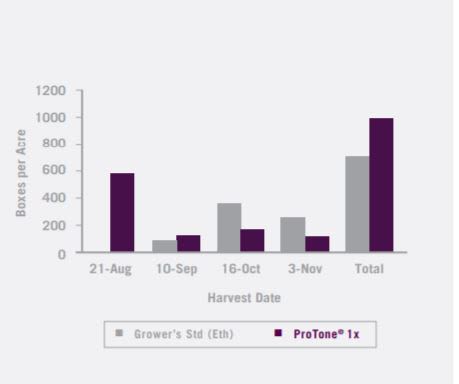

- Early Color = Increased Flexibility ‘Crimson Seedless’ Kingsburg, California

Early color development gives flexibility in harvest scheduling. By being ready to meet market demands earlier in the season more opportunities for selling at a premium price exist. In addition, by reducing crop loads early in the season better coloring of the remaining crop can occur. In Kingsburg, California use of ProTone® significantly increased the number of boxes that this grower was able to pick early in the season. In addition, he was able to harvest nearly 300 more boxes than he had with his standard coloring program, netting an additional $4,500 per acre

- Early Color = Increased Flexibility ‘Flame Seedless’

Early color development gives flexibility in harvest scheduling plus allows capitalizing on premium prices that normally exist earlier in the market. In addition, by reducing crop loads early in the season better coloring of the remaining crop can occur. In certain years, growers can have as much as 15% to 25% of the crop not harvested due to poor coloring. The use of ProTone® in the Augrabies area, Northern Cape, significantly increased the percentage of harvestable bunches that this grower was able to pick early in the season. The various ProTone® combinations resulted in approximately 70% harvestable bunches (accumulated) at Harvest 2, compared to the grower’s ethephon reference of 36% harvestable bunches. This will result in premium prices on the early market and significant increase in income per hectare.