Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Features

VDM® Alloy 59 is characterized by:

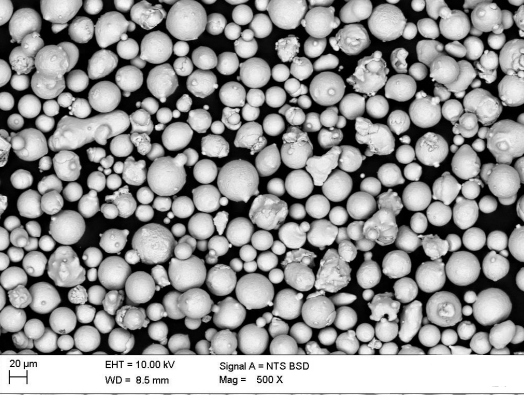

- Spherical particles

- High purity

- Low oxygen content

- Excellent resistance against a multitude of corrosive media under oxidizing and reducing conditions

- Very good weldability

- Corrosion Resistance

The corrosion resistance depends on the processing and heat treatment of the material. The conventionally produced VDM Alloy 59 has no propensity for grain boundary dispersions in hot forming or welding. The alloy can therefore be used in many chemical processes with oxidizing and reducing media. Furthermore, VDM® Alloy 59 is more resilient against chloride ion attack due to its high nickel, chromium and molyb-denum concentrations.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Applications

VDM® Powder 59 is suitable for a wide spectrum of applications in chemistry, petro chemistry, energy and environmen-tal engineering. Typical applications are:

- Plant components for organic chemistry processes with media containing chloride, especially where catalytic systems on chloride basis are used.

- Plant parts in active substance preparation and the pharmaceuticals industry

- Components for seawater and concentrated brines

- Equipment and components for geothermal energy and acid gas applications and for flue gas desulfurization (FGD) in fossil fuel power plants and waste incineration plants

Properties

- Chemical Properties

- Physical Properties

- Microstructural Properties

VDM® Alloy 59 has a cubic, face-centered crystal structure.

| Value | Units | Test Method / Conditions | |

| Aluminum Content | 0.1 - 0.4 | wt. % | - |

| Carbon Content | max. 0.01 | wt. % | - |

| Cobalt Content | max. 0.3 | wt. % | - |

| Chromium Content | 22 - 24 | wt. % | - |

| Copper Content | max. 0.5 | wt. % | - |

| Iron Content | max. 1.5 | wt. % | - |

| Manganese Content | max. 0.5 | wt. % | - |

| Molybdenum Content | 15 - 16.5 | wt. % | - |

| Phosphorus Content | max. 0.015 | wt. % | - |

| Sulfur Content | max. 0.01 | wt. % | - |

| Silicon Content | max. 0.1 | wt. % | - |

| Value | Units | Test Method / Conditions | |

| Density (20°C) | max. 8.6 | g/cm³ | - |

| Melting Range | 1310 - 1360 | °C | - |

Regulatory & Compliance

- Designations and Standards

Standard Material designation

EN 2.4605 – NiCr23Mo16Al

ISO 15156/MR 0175 UNS N06059

Packaging & Availability

- Availability

According to the AM process requirements of our customers, VDM® Powder 59 is available in a wide range of particle fractions from 15 to 250 μm.

Particle size distribution

[μm]Oxygen content

%Porosity < 10μ (pore area)

%15-53 < 0.03

< 0.5

53-150