Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Chemical Composition

Depending on the use conditions, stricter analysis limits apply to certain alloy elements. VDM® Powder 780 contains low amounts of oxygen of up to 0.03%.

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Features

VDM® Powder 780 is characterized by:

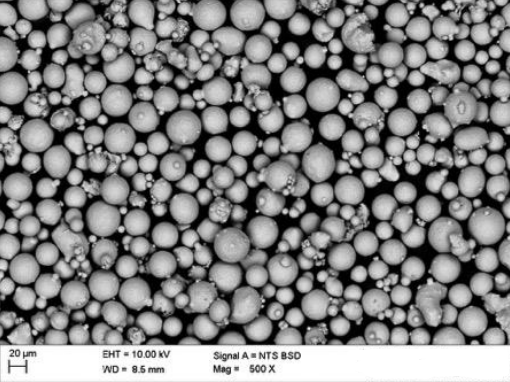

- Spherical particles

- High purity

- Low oxygen content

- Good weldability

- Higher application temperature (potentially up to 750°C)

- High temperature oxidation resistance

- Corrosion Resistance

As a result of the high chromium and cobalt content, conventionally manufactured VDM® Alloy 780 has a good high temperature oxidation resistance.

Applications & Uses

- Markets

- Applicable Processes

- Base Chemicals End Uses

- Applications

VDM® Powder 780 can be used for many demanding applications. Originally, it was developed for static and rotating components in aircraft turbines such as housings, mounting elements and turbine disks.

The material can also be used for static and rotating components in stationary gas turbines, rocket drives and space-craft, motor vehicle turbo chargers, high-strength screws, springs and mounting elements, and for heat-resistant tools in forgeries, extruders and separating shearers.

Properties

- Chemical Properties

- Physical Properties

- Microstructural Properties

VDM® Powder 780 has an austenitic microstructure where different phases can occur. By means of different heat treat-ments, graduated mechanical properties of the material can be achieved. The excellent mechanical properties of VDM® Powder 780 result from the γ’-formation during precipitation hardening.

| Value | Units | Test Method / Conditions | |

| Aluminum Content | 1 - 3 | wt. % | - |

| Boron Content | max. 0.02 | wt. % | - |

| Carbon Content | max. 0.1 | wt. % | - |

| Cobalt Content | 22 - 28 | wt. % | - |

| Chromium Content | 16 - 20 | wt. % | - |

| Copper Content | max. 0.5 | wt. % | - |

| Iron Content | max. 4.0 | wt. % | - |

| Manganese Content | max. 0.5 | wt. % | - |

| Molybdenum Content | 2 - 4 | wt. % | - |

| Nb + Ta | 4 - 6 | wt. % | - |

| Phosphorus Content | max. 0.03 | wt. % | - |

| Sulfur Content | max. 0.015 | wt. % | - |

| Silicon Content | max. 0.3 | wt. % | - |

| Titanium Content | 0.1 - 1 | wt. % | - |

| Value | Units | Test Method / Conditions | |

| Density (20°C) | max. 8.25 | g/cm³ | - |

| Melting Range | 1240 - 1355 | °C | - |

Regulatory & Compliance

- Designations and Standards

Standard Material designation

EN 2.4960 - NiCr18Co25Nb5Mo3Al2

Packaging & Availability

- Availability

According to the AM process requirements of our customers, VDM® Powder 780 is available in a wide range of particle fractions from 10 to 250 μm.

Standard particle fractions

Particle size distribution

[μm]Oxygen content

%Porosity < 10μ (pore area)

%15-53 < 0.03

< 0.5

53-150