Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Chemical Composition

VDM® Powder CoCr F75 contains low amounts of oxygen of up to 0.03 %.

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Features

VDM® Powder CoCr F75 is characterized by:

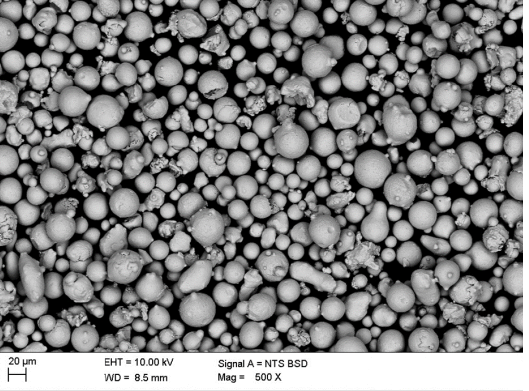

- Spherical particles

- High purity

- Low oxygen content

- Good corrosion and temperature resistance

- Excellent wear resistance

- Corrosion Resistance

As a result of the high chromium content, VDM® Powder CoCr F75 has very good general corrosion and temperature resistance.

Applications & Uses

- Markets

- Applicable Processes

- Applications

Due to its good corrosion, temperature and wear resistance, VDM® Powder CoCr F75 is intended for the use as medical prosthetic implant like knee implants, metal-to-metal hip joints or dental prosthetics. Furthermore, it is appropriate for high-temperature engineering applications like aero- and land-based gas turbines as gas nozzles and vanes for industrial gas turbines.

Properties

- Chemical Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Aluminum Content | max. 0.10 | wt. % | - |

| Boron Content | max. 0.010 | wt. % | - |

| Carbon Content | max. 0.35 | wt. % | - |

| Chromium Content | 27 - 30 | wt. % | - |

| Iron Content | max. 0.75 | wt. % | - |

| Manganese Content | max. 1.0 | wt. % | - |

| Molybdenum Content | 5 - 7 | wt. % | - |

| Nitrogen Content | max. 0.25 | wt. % | - |

| Nickel Content | max. 0.50 | wt. % | - |

| Phosphorus Content | max. 0.020 | wt. % | - |

| Sulfur Content | max. 0.010 | wt. % | - |

| Silicon Content | max. 1.0 | wt. % | - |

| Titanium Content | max. 0.10 | wt. % | - |

| Tungsten Content | max. 0.20 | wt. % | - |

| Value | Units | Test Method / Conditions | |

| Density (20°C) | max. 8.3 | g/cm³ | - |

| Melting Range | 1350 - 1430 | °C | - |

Regulatory & Compliance

- Designations and Standards

Standard Material designation

ISO 5832-12 / 5832-4

ASTM F1537-11 / F75 UNS R31538 / R30075

Packaging & Availability

- Availability

According to the AM process requirements of our customers, VDM® Powder CoCr F75 is available in a wide range of particle fractions from 15 to 250 μm.

Particle size distribution

[μm]Oxygen content

%Porosity < 20μ (pore area)

%15-53 < 0.03

< 0.5

53-150