Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Chemical Composition

VDM® Powder X contains low amounts of oxygen of up to 0.03%.

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Features

VDM® Powder X is characterized by:

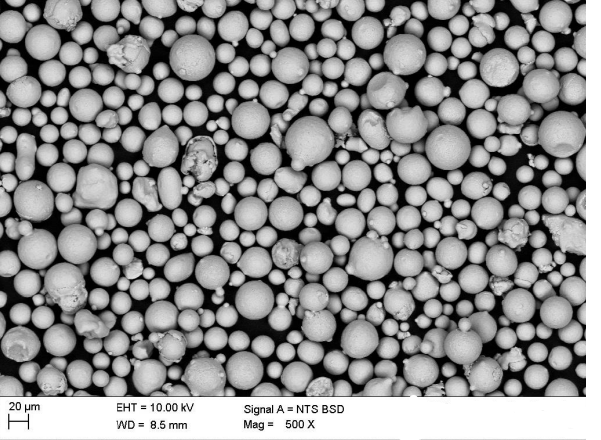

- Spherical particles

- High purity

- Low oxygen content

- Excellent oxidation resistance up to 1,200°C (2,190°F)

- High-temperature strength

- Good resistance to stress corrosion cracking

- Corrosion Resistance

The corrosion resistance depends on the processing and heat treatment of the material. The conventionally produced VDM® Alloy X usually shows excellent oxidation resistance up to 1,200°C (2,190°F) and can be used in neutral as well as in reducing atmospheres. VDM® Alloy X is resistant in carburizing and nitriding atmospheres.

Applications & Uses

- Applications

- Base Chemicals End Uses

- Applications

Due to its corrosion resistance in various atmospheres up to very high temperatures, and excellent high-temperature strength, VDM® Powder X finds wide application in high-temperature services.

Typical applications include:

- Components for industrial and aircraft gas turbines (combustion chambers, honeycombs, housings etc.)

- Industrial furnace parts, support rolls, grids, wire belts and radiant tubes

- Pigtails in petrochemical furnaces

- High-temperature gas cooled nuclear reactors

Properties

- Chemical Properties

- Physical Properties

- Microstructural Properties

VDM® Powder X has a face-centered cubic structure.

| Value | Units | Test Method / Conditions | |

| Carbon Content | 0.05 - 0.15 | wt. % | - |

| Cobalt Content | 0.5 - 2.5 | wt. % | - |

| Chromium Content | 20.5 - 23.0 | wt. % | - |

| Iron Content | 17.0 - 20.0 | wt. % | - |

| Manganese Content | max. 1.0 | wt. % | - |

| Molybdenum Content | 8.0 - 10.0 | wt. % | - |

| Phosphorus Content | max. 0.04 | wt. % | - |

| Sulfur Content | max. 0.03 | wt. % | - |

| Silicon Content | max. 1.0 | wt. % | - |

| Tungsten Content | 0.2 - 1.0 | wt. % | - |

| Value | Units | Test Method / Conditions | |

| Density (20°C) | max. 8.3 | g/cm³ | - |

| Melting Range | 1,260 - 1,355 | °C | - |

Regulatory & Compliance

- Designations and Standards

Standard Material designation

EN 2.4665 – NiCr22Fe18Mo

ISO NiCr21Fe18Mo9 UNS N06002 AFNOR NC22FeD

Packaging & Availability

- Availability

According to the AM process requirements of our customers, VDM® Powder X is available in a wide range of particle fractions from 15 to 250 μm.

Standard particle fractions

Particle size distribution

[μm]Oxygen content

%Porosity < 10μ (pore area)

%15-53 < 0.03

< 0.5

53-150