Knowde Enhanced TDS

Identification & Functionality

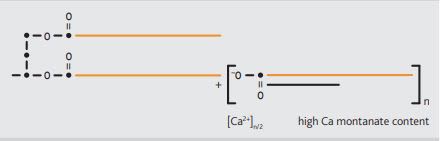

- Chemical Family

- Technologies

- Product Families

- Structural Characteristics

Features & Benefits

- Materials Features

- General Advantages

WARADUR® OPplus is suitable for engineering plastics, thermosets, PVC, etc. WARADUR® OPplus is extremely versatile and suitable for a wide range of plastics applications as a multi-purpose additive. The use of WARADUR® OPplus can lead to the following positive effects in the processes compounding, injection molding and extrusion/blow molding:

- Reduction of mold temperature in injection molding Reduction of melt temperature (compounding, injection molding, extrusion/blow molding)

- Increasing injection speeds in injection molding

- Realization of higher filler contents under the same processing conditions

- Realization of long flow paths

- Easy processing in tools that implement very different component thicknesses

- Improvement of the surface quality of injection molded parts

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Use Level

- 0.3 to 0.6 %

- Recommended Application Areas

- Thermoplastics: PA, PBT, PET, PC, PVC, ABS, PLA, styrenics

- Thermosets: epoxy resins, phenolic resins, polyurethane

- Dispersing agents for color masterbatches and filled (talc, glass fiber) plastics

- We recommend the using from 0.3 to 0.6 %.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Acid Value | max. 10 | mg KOH/g | ISO 2114 |

| Melting Range | approx. 88 - 114 | °C | DSC |

| Solidification Range | approx. 92 - 65 | °C | DSC |

Safety & Health

- Product Safety

WARADUR® OPplus

- is made from fossilized plant wax

- is not classified as carcinogenic, mutagenic or reprotoxic; no health or environmental hazards are known, provided it is applied in industrial and professional settings

Packaging & Availability

- Packaging Type

- Packaging

- Paper bag

- Big Bag

Storage & Handling

- Storage

Store at ambient temperature on a dry place. Protect from heat/overheating and direct sunlight. The maximum shelf life is 5 years after production. Thereafter, tests of the chemical characteristics are recommended. After delivery, a minimum remaining shelf life at the customer of 1.5 years is warranted.