Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

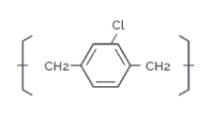

- Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Application Method

- Coating Type

- Uses

Parylene C is the best choice for:

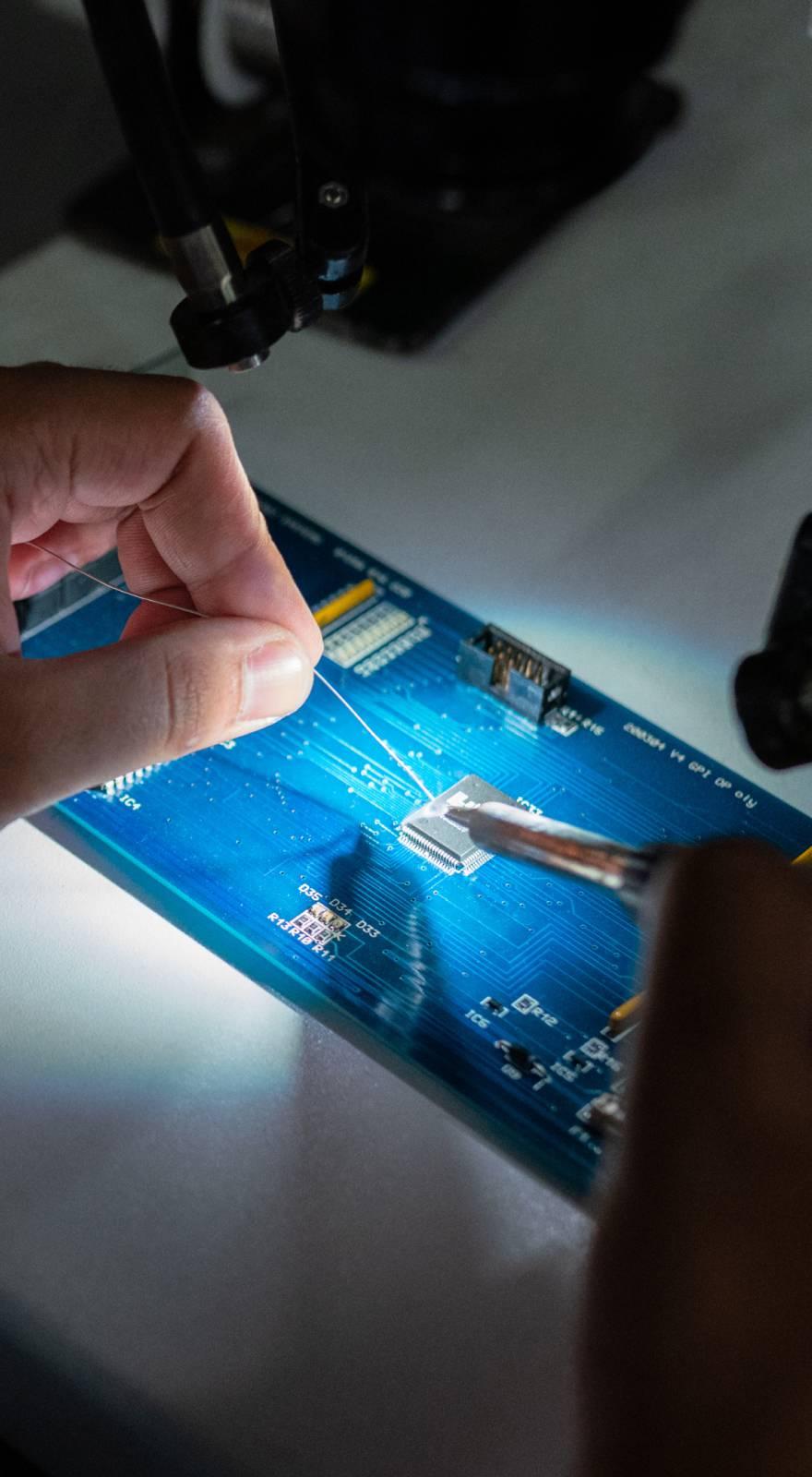

- Implantable medical devices.

- Pinhole-free barrier layers to electronics or materials from harsh environments.

- Encapsulating electronics to provide dielectric protection.

Properties

- Flame Rating

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Film Properties

- Electrical Properties

- Chemical Resistance

- Electrical Properties

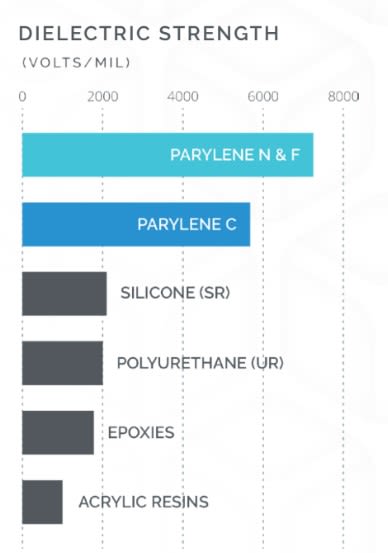

- Parylene is a material with exceptional electrical insulation properties that can be applied in a conformal thin film.

- This combination allows parylene to be used as a precision dielectric layer in a variety of applications.

- Parylene’s breakdown voltage is determined by the coating thickness.

- When compared to epoxy, silicones, and urethane coatings, all parylene types have an extremely high dielectric strength.

- Parylene N is a unique dielectric material because of the extremely low dissipation factor which changes only slightly with frequency.

- The chlorine atom in parylene C increases the dielectric constant and dissipation factor when compared to parylene N.

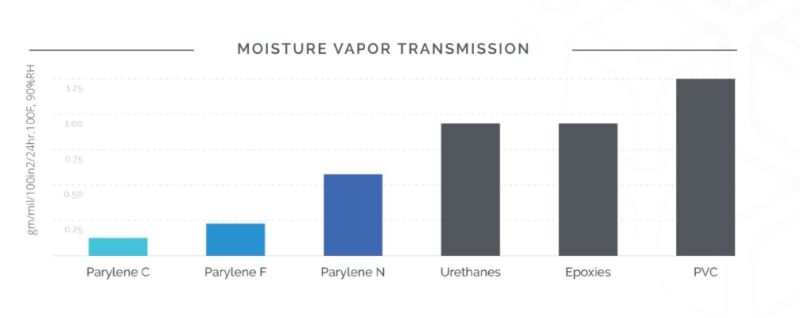

- Barrier Properties

- Parylene is an extremely effective moisture and chemical barrier layer that can be used to protect materials from an incompatible environment.

- Parylene is able to fully encapsulate medical devices, electronics and oxidative materials from harsh environments with a very thin and conformal parylene layer.

- Parylene is chemically resistant to almost every solvent, acid and alkaline chemistry commonly used.

- This allows parylene to be used in environments that simply are impossible for other conformal coatings.

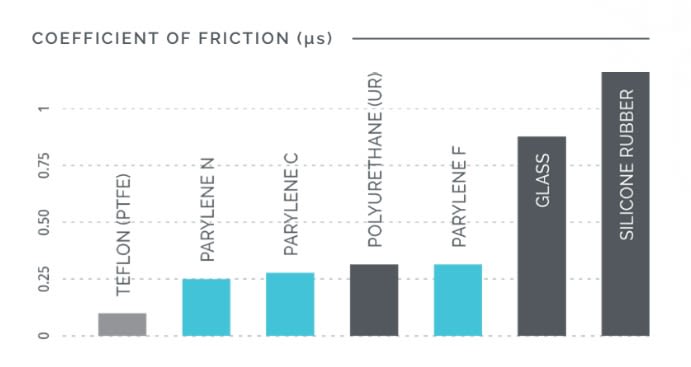

- Mechanical Properties

- Parylene is a crystalline polymer which results in generally high mechanical strength.

- Parylene has a relatively high tensile and yield strength compared to other polymer coatings.

- Parylene has a hardness higher than polyurethane and epoxy. However, it has the approximate hardness of human skin.

- Although parylene’s wear resistance is substantial, it isn’t recommended to be used in applications with repeated abrasion with harder materials.

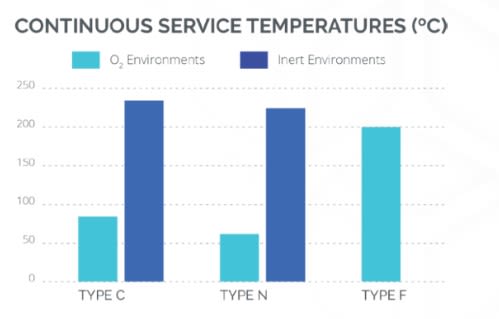

- Thermal Properties

- Parylene, like all polymers, has an ideal temperature operating range which is dependent on the application and environment.

- At temperatures outside the ideal temperature operating range, parylene will start to become translucent or yellow and will become brittle.

- The operating temperature range increases significantly if parylene can be used in the absence of air or in inert atmospheres. In an oxygen-free environment, oxidative degeneration does not take place.

- Degradation is due primarily to the thermal cleavage of carbon-carbon bonds.

- If high temperature is a concern, VSI recommends every application is looked at and tested individually.

- Each parylene type’s melting temperature defines an upper limit. The table to the right gives guidelines for 1,000 hour use and continuous use to demonstrate parylene melting points.

- On the other end of the temperature spectrum, parylene is outstanding in cryogenic applications. As an example, steel panels coated with parylene C that were chilled in liquid nitrogen to -160°C withstood impacts of more than 100 in/lb.

- Unsupported 2-mil films of parylene C were flexed 190 degrees six times at -165°C before failure occurred.

- At even lower temperatures, near absolute zero, tests show that parylene N provides the best electrical insulation of any known plastic.

- Neither electrical or physical properties are noticeably affected by cycling from -270°C to room temperature.

| Value | Units | Test Method / Conditions | |

| Coefficient of Friction (static and dynamic) | 0.29 | — | — |

| Hardness | R80 | — | Rockwell |

| % Elongation to Break | 20 - 200 | % | — |

| Young’s Modulus | 2.8 | GPa | — |

| Tensile Strength | 10000.0 | psi | — |

| Tensile Strength | 68.9 | MPa | — |

| Yield Strength | 8000.0 | psi | — |

| Yield Strength | 55.2 | MPa | — |

| Elongation to Break | 20 - 200 | % | — |

| Elongation at Yield | 2.9 | % | — |

| Density | 1.289 | g/cm³ | — |

| Hardness (Rockwell) | R80 | R | — |

| Coefficient of Friction (Static) | 0.29 | — | — |

| Coefficient of Friction (Dynamic) | 0.29 | — | — |

| Value | Units | Test Method / Conditions | |

| Gas Permeability (Oxygen at 25°C) | 2.8 | cc*mm/m²*day*atm | — |

| Penetration Power | 5X | — | — |

| USP Class VI Polymer | Yes | — | — |

| Gas Permeability (Nitrogen) | 0.4 | cc*mm/m²*day*atm | — |

| Gas Permeability (Carbon Dioxide) | 3 | cc*mm/m²*day*atm | — |

| Gas Permeability (Hydrogen) | 43.3 | cc*mm/m²*day*atm | — |

| Value | Units | Test Method / Conditions | |

| Short Term Service Temperature (in oxygen environments) | 115 | °C | — |

| Continuous Service Temperature (in oxygen environments) | 80 | °C | — |

| Short Term Service Temperature (in inert environments) | 350 | °C | — |

| Continuous Service Temperature (in inert environments) | 230 | °C | — |

| Thermal Conductivity (at 25° C) | 0.084 | W/m*K | — |

| Specific Heat | 0.17 | cal/g*°C | — |

| Melting Point | 290.0 | °C | — |

| Melting Point | 290 | °C | — |

| Short-term Service Temperature (Oxygen Environment) | 115.0 | °C | — |

| Short-term Service Temperature (Inert Environment) | 350.0 | °C | — |

| Continuous Service Temperature (Oxygen Environment) | 80.0 | °C | — |

| Continuous Service Temperature (Inert Environment) | 230.0 | °C | — |

| Linear Coefficient of Thermal Expansion (at 25° C) | 35.0 | ppm/°C | — |

| Linear Coefficient of Thermal Expansion (at 25° C) | 35 | ppm/°C | — |

| Thermal Conductivity (25°C) | 0.084 | W/mK | — |

| Specific Heat (20°C) | 17.0 | cal/g°C | — |

| Value | Units | Test Method / Conditions | |

| Nitrogen Gas Permeability (25°C) | 0.4 | (ccxmm)/(m²xdayxatm) | — |

| Oxygen Gas Permeability (25°C) | 2.8 | (ccxmm)/(m²xdayxatm) | — |

| Carbon Dioxide Gas Permeability (25°C) | 3.0 | (ccxmm)/(m²xdayxatm) | — |

| Hydrogen Gas Permeability (25°C) | 43.3 | (ccxmm)/(m²xdayxatm) | — |

| Value | Units | Test Method / Conditions | |

| Dielectric Strength (25.4microns) | 220.0 | V/micron | — |

| Dielectric Strength (0.001”) | 5600.0 | V/mil | — |

| Volume Resistivity (23°C, 50% RH) | 8.8x10¹⁶ | ohm-cm | — |

| Surface Resistivity (23°C, 50% Relative Humidity) | 1x10¹⁴ | ohms | — |

| Dielectric Constant (60Hz) | 3.15 | — | — |

| Dielectric Constant (1KHz) | 3.1 | — | — |

| Dielectric Constant (1MHz) | 2.95 | — | — |

| Dielectric Constant (6GHz) | 3.06 - 3.10 | — | — |

| Dielectric Strength (at 0.001”) | 5.6 | KV/mil | — |

| Dissipation Factor (60Hz) | 0.02 | — | — |

| Dissipation Factor (1KHz) | 0.019 | — | — |

| Volume Resistivity (at 23°C, 50% RH) | 8.8x10¹⁶ | ohm-cm | — |

| Dissipation Factor (1MHz) | 0.013 | — | — |

| Surface Resistivity (at 23°C, 50% Relative Humidity) | 1x10¹⁴ | ohms | — |

| Dissipation Factor (6GHz) | 0.0002 - 0.0010 | — | — |

| Dielectric Constant (at 1MHz) | 2.95 | — | — |

| Dissipation Factor (at 1MHz) | 0.013 | — | — |

| Value | Units | Test Method / Conditions | |

| Hydrochloric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.0 | % | — |

| Hydrochloric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.0 | % | — |

| Hydrochloric Resistance (37%, Non-Oxidizing Acid, 25°C) | 0.0 | % | — |

| Hydrochloric Resistance (37%, Non-Oxidizing Acid, 75°C) | 4.1 | % | — |

| Sulfuric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.3 | % | — |

| Sulfuric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.2 | % | — |

| Sulfuric Resistance (95 - 98%, Non-Oxidizing Acid, 25°C) | 0.4 | % | — |

| Sulfuric Resistance (95 - 98%, Non-Oxidizing Acid, 75°C) | 5.1 | % | — |

| Nitric Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.1 | % | — |

| Nitric Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.1 | % | — |

| Nitric Resistance (71%, Non-Oxidizing Acid, 25°C) | 0.2 | % | — |

| Nitric Resistance (71%, Non-Oxidizing Acid, 75°C) | 0.0 | % | — |

| Chromic Resistance (10%, Non-Oxidizing Acid, 25°C) | 0.1 | % | — |

| Chromic Resistance (10%, Non-Oxidizing Acid, 75°C) | 0.0 | % | — |

| Chromic Resistance (74%, Non-Oxidizing Acid, 25°C) | 0.0 | % | — |

| Chromic Resistance (74%, Non-Oxidizing Acid, 75°C) | 7.8 | % | — |

| Sodium Hydroxide Resistance (10%, Base, 25°C) | 0.0 | % | — |

| Sodium Hydroxide Resistance (10%, Base, 75°C) | 0.5 | % | — |

| Ammonium Hydroxide Resistance (10%, Base, 25°C) | 0.2 | % | — |

| Ammonium Hydroxide Resistance (10%, Base, 75°C) | 0.4 | % | — |

| De - Ionized Water Resistance (100%, Inert, 25°C) | 0.0 | % | — |

| De - Ionized Water Resistance (100%, Inert, 75°C) | 0.0 | % | — |

| Isopropyl Resistance (Alcohol, 25°C) | 0.1 | % | — |

| Isopropyl Resistance (Alcohol, 75°C) | 0.2 | % | — |

| Iso - Octane Resistance (Aliphatic Hydrocarbon, 25°C) | 0.4 | % | — |

| Iso - Octane Resistance (Aliphatic Hydrocarbon, 75°C) | 0.5 | % | — |

| Pyridine Resistance (Amine, 25°C) | 0.5 | % | — |

| Pyridine Resistance (Amine, 75°C) | 0.7 | % | — |

| Xylene Resistance (Mixed, 25°C) | 2.3 | % | — |

| Xylene Resistance (Mixed, 75°C) | 3.3 | % | — |

| Trichloroethylene Resistance (TCE, 25°C) | 0.8 | % | — |

| Trichloroethylene Resistance (TCE, 75°C) | 0.9 | % | — |

| Chlorobenzene Resistance (Chlorinated Aromatic, 25°C) | 1.5 | % | — |

| Chlorobenzene Resistance (Chlorinated Aromatic, 75°C) | 2.0 | % | — |

| O-Dichlorobenzene Resistance (Chlorinated Aromatic, 25°C) | 3.0 | % | — |

| O-Dichlorobenzene Resistance (Chlorinated Aromatic, 75°C) | 1.4 | % | — |

| Trichlorotrifluoroethane Resistance (Fluorocarbon, 25°C) | 0.2 | % | — |

| Trichlorotrifluoroethane Resistance (Fluorocarbon, 75°C) | 0.3 | % | — |

| Acetone Resistance (Ketone, 25°C) | 0.9 | % | — |

| Acetone Resistance (Ketone, 75°C) | 0.9 | % | — |

| 2,4-Pentanedione (Ketone, 25°C) | 1.2 | % | — |

| 2,4-Pentanedione (Ketone, 75°C) | 1.8 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Regulation

Parylene C meets IPC-CC-830 or MIL-I-46058C standards.