Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

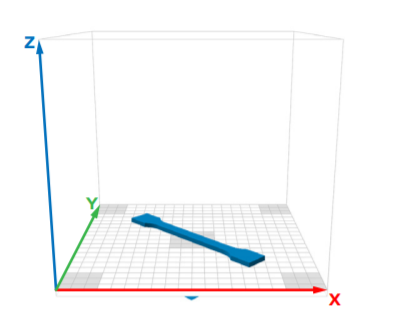

- SPEEDOMETER.

3D printed with a low-cost Z-ABS filament, the prototype of motorcycle speedometer allows engineers to see how this part would work in a full-sized vehicle.

-

Basic material

Z-ABS is the basic 3D printing filament. Easy post-processing, mat surface and wide color range make Z-ABS a natural choice for fast, affordable prototyping and low-scale production.

- Low-cost 3D printing

Z-ABS 3D printing filament lets you affordably experiment even with the most creative designs before going on with full production. Ease of use and low cost make it perfect for rapid prototyping on tight budget.

- Easy post-processing

Customize your 3D prints by using various post-processing techniques. Smoothen models with acetone vapors, use sandpapers or cover 3D printed objects with paints and varnishes. Z-ABS is an excellent material for demanding makers and hobbyists.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Prototypes

- Concept models

- Low-cost drafting

- Casings

- Figurines

- Gaming and toys

- Gadgets and decorative accessories

- Display models

- DIY projects

- Educational aids

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 30.46 | MPa | ISO 527:1998 |

| Breaking Stress | 25.89 | MPa | ISO 527:1998 |

| Elongation (Max Tensile Stress) | 4.52 | % | ISO 527:1998 |

| Elongation (Break) | 11.08 | % | ISO 527:1998 |

| Bending Stress | 46.3 | MPa | ISO 178:2011 |

| Flexural Modulus | 1.08 | GPa | ISO 178:2011 |

| Izod Impact (Notched) | 8.93 | kJ/m2 | ISO 180:2004 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 107.89 | °C | ISO 11357-3:2014 |

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (Load 10 kg Temperature 220°C) | 11.75 | g/10min | ISO 1133:2006 |

| Hardness | 69.2 | Shore D | ISO 868:1998 |

| Specific Density | 1.195 | g/cm3 | ISO 1183-3:2003 |

Technical Details & Test Data

- Test Data

Samples of Z-ABS used to carry out the tests were built on Zortrax M200. The general print parameters utilized are noted below:

- Z-SUITE: v2.2.0.0

- Layer thickness: 0.19 mm;

- Quality: High;

- Seam: Normal;

- Infill: Solid,

- Fan Speed: Auto;

- Surface Layers:

- Top: 7 (default);

- Bottom: 4 (default);

Packaging & Availability

- Available Colours

- Cool Gray

- Pure Black

- Pure White