Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

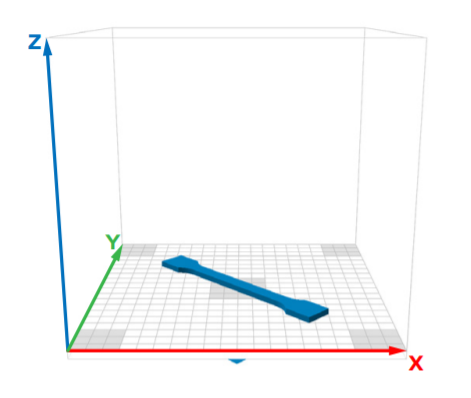

- BUS PIRATE.

Casing for the bus pirate installed on a circuit board. The electrostatic sensitive device is protected by the casing 3D printed with Z-ESD material reducing the risk of damage.

-

Electrostatic discharge protection

Z-ESD material maintains surface resistivity in a wide range from 10^6 to 10^9 Ω/sq. The 3D printed casings and tools allow you to protect delicate components against electrostatic discharges.

- Industrial grade

Very low shrinkage of Z-ESD guarantees accuracy and reliability of every print. 3D print precise end-use parts to cut costs and lead times.

- Chemical resistance

Use Z-ESD to 3D print parts meant for work in adverse environments. You can expose the 3D printed objects to most acids, alcohols, and weak alkalies with no risk of deformation or damage.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Industrial Parts And Tools

- End-Use Parts

- Casings For Electronic Devices

- Parts Required To Be Resistant To Chemicals And Electrostatic Discharge

Properties

- Color

- Physical Form

- Mechanical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 32.88 | MPa | ISO 527:1998 |

| Breaking Stress | 30.73 | MPa | ISO 527:1998 |

| Elongation (Max Tensile Stress) | 4.16 | % | ISO 527:1998 |

| Elongation (Break) | 4.46 | % | ISO 527:1998 |

| Bending Stress | 47.7 | MPa | ISO 178:2011 |

| Flexural Modulus | 1.5 | GPa | ISO 178:2011 |

| Izod Impact (Notched) | 4.92 | kJ/m2 | ISO 180:2004 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 79.93 | °C | ISO 11357-3:2014 |

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (Load 2.16 kg Temperature 230°C) | 6.02 | g/10 min | ISO 1133:2006 |

| Hardness | 69.2 | Shore D | ISO 868:1998 |

| Melt Flow Rate (Load 5 kg Temperature 230°C) | 8.57 | g/10 min | ISO 1133:2006 |

| Specific Density | 1.285 | g/cm³ | ISO 1183-3:2003 |

| Surface Resistivity | 106 – 109 | Ohm/sq | IEC 60093 |

Technical Details & Test Data

- Test Data

Samples of Z-ESD used to carry out the tests were built on Zortrax M200. The general print parameters utilized are noted below:

- Z-SUITE: v2.2.0.0

- Layer thickness: 0.19 mm;

- Quality: High;

- Seam: Normal;

- Infill: Solid,

- Fan Speed: Auto;

- Surface Layers:

- Top: 7 (default);

- Bottom: 4 (default);

Packaging & Availability

- Available Colours

Black