Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

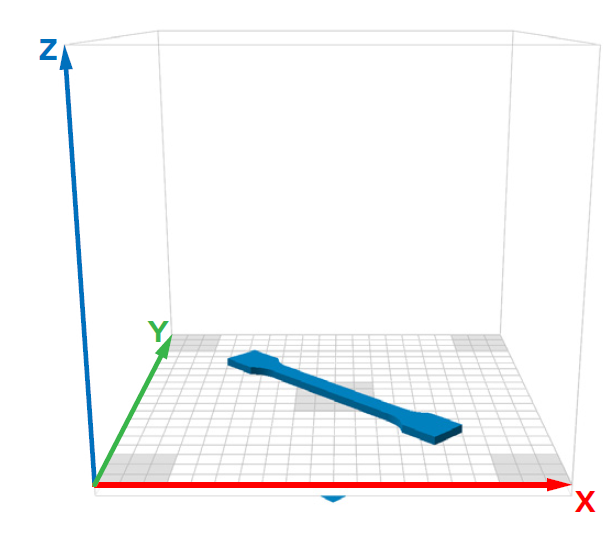

- HEATER VALVE.

Prototype of a heater valve 3D printed with Z-ULTRAT Plus. Improved durability allows for thorough testing in real conditions.

-

High durability

Z-ULTRAT Plus is exceptionally resistant to impacts and has improved interlayer adhesion when compared to standard ABS. The filament provides 3D printed end-use parts with unyielding durability.

-

High-detail 3D printing

Z-ULTRAT Plus filament is perfect for 3D printing small, complex working mechanisms and intricate prototypes due to its dimensional accuracy and superior surface quality.

-

Works with Z-SUPPORT Premium

Although Z-ULTRAT Plus is based on ABS, its composition have been altered to allow simultaneous 3D printing with water-soluble PVA-based Z-SUPPORT Premium filament.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Industrial Prototyping

- Intricate Constructions Made Of Multiple Elements

- Complex Moving Mechanisms

- Detailed Architectural Mock-Ups

- Small Elements Rich In Details

- Hollow End-Use Parts

- Models With Complicated Organic Shapes, Difficult To Obtain By Traditional Methods

Properties

- Physical Form

- Mechanical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 32.02 | MPa | ISO 527:1998 |

| Breaking Stress | 31.32 | MPa | ISO 527:1998 |

| Elongation (Max Tensile Stress) | 3.41 | % | ISO 527:1998 |

| Elongation (Break) | 3.44 | % | ISO 527:1998 |

| Bending Stress | 51.7 | MPa | ISO 178:2011 |

| Flexural Modulus | 1.51 | GPa | ISO 178:2011 |

| Izod Impact (Notched) | 7.71 | kJ/m2 | ISO 180:2004 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 70.19 | °C | ISO 11357-3:2014 |

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (Load 5 kg Temperature 260°C) | 108.1 | g/10 min | ISO 1133:2006 |

| Hardness | 67 | Shore D | ISO 868:1998 |

| Specific Density | 1.141 | g/cm³ | ISO 1183-3:2003 |

Technical Details & Test Data

- Test Data

Samples of Z-ULTRAT Plus used to carry out the tests were built on Zortrax Inventure.

The general print parameters utilized are noted below:- Z-SUITE: v2.3.1.0

- Layer thickness: 0.19 mm;

- Quality: High;

- Seam: Normal;

- Infill: Solid,

- Fan Speed: Auto;

- Surface Layers:

- Top: 7 (default);

- Bottom: 4 (default);

Packaging & Availability

- Available Colours

- Blue

- Pure Black

- Red

- Ivory

- Graphite