- Polymer Name:Polyamide 12 (PA 12)

- Processing Methods:Injection Molding

- Fillers Included:Glass Fiber

- Additives Included:Heat Stabilizer

- Flexural Modulus:4995.25 - 4995.25 MPa

- Materials Features:Oil Resistant, Shorter Cycle Time, Excellent Mold Release, Heat Stabilized, UV Resistant, Good Light Stability, Good Weather Stability, Medium Viscosity, Electrically Insulating, Fuel Resistant, Good Thermal Stability

- Color:Black

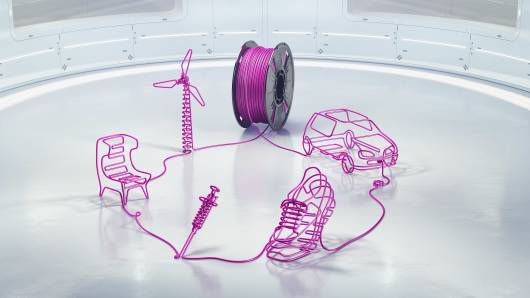

VESTAMID® L1833 BK 9.7623 is a 23% glass fiber-reinforced, easily demoldable, and heat-stabilized polyamide 12 compound. This compound is specifically formulated to provide efficient production of injection molded parts with short cycle times, thanks to its excellent mold release properties. VESTAMID® L1833 BK 9.7623 is supplied as cylindrical granules, conveniently packaged in moisture-proof bags, ensuring optimal storage conditions. Experience the reliability and performance of VESTAMID® L1833 BK 9.7623 in your injection molding applications. This compound, with its glass fiber reinforcement, offers enhanced strength and rigidity, while its demolding characteristics and heat stability contribute to efficient production. Choose VESTAMID® L1833 BK 9.7623 for its exceptional properties, ease of processing, and suitability for a wide range of injection molded parts.