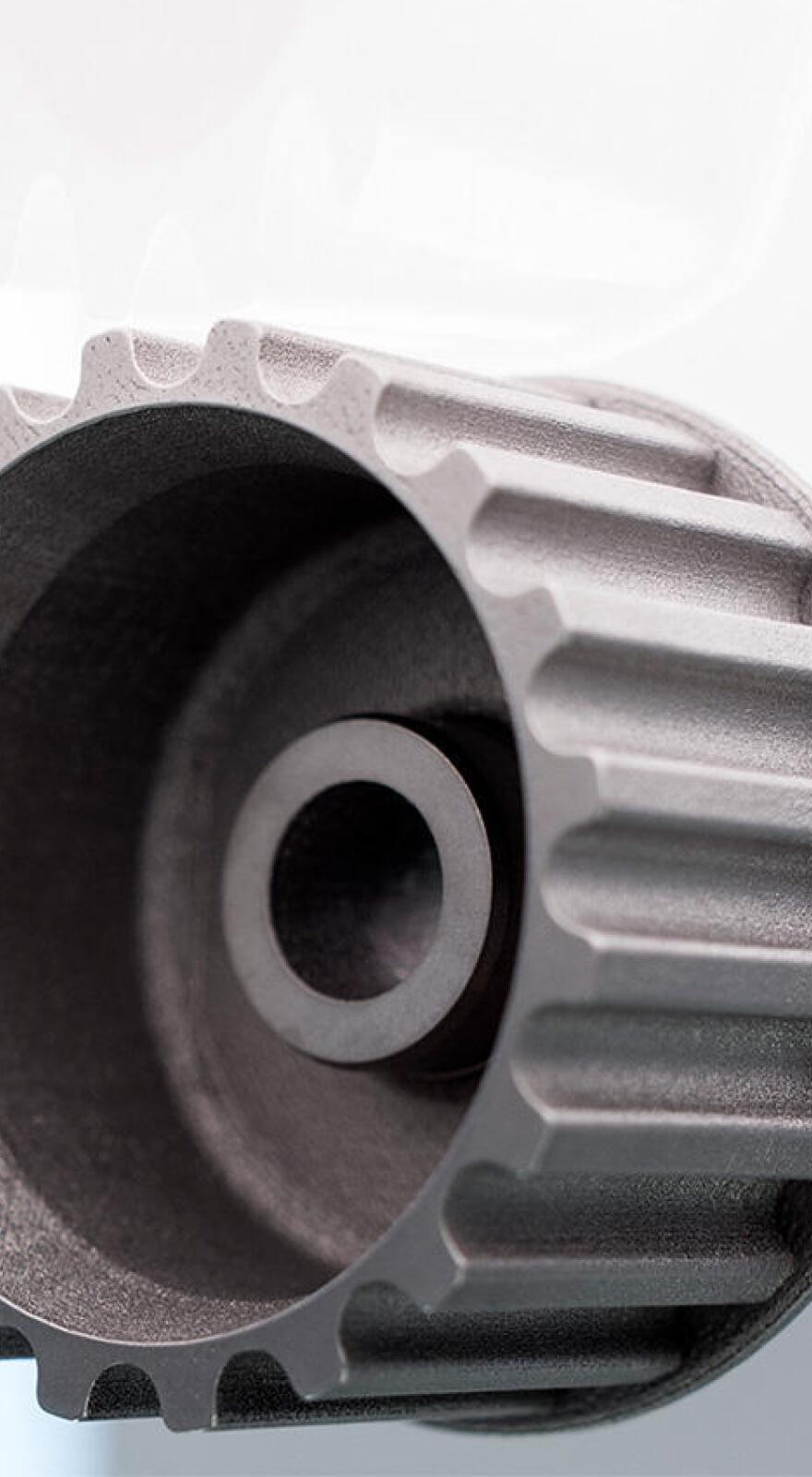

A styrene-based, expendable pattern casting material, compatible with most standard foundry processes.Applications Create patterns directly rather than through indirect methods Complex investment casting patterns Reactive metals like titanium Low melt-temperature metals such as aluminum, magnesium and zinc Ferrous and non-ferrous metals Economic, low-volume production castings without tooling Smaller parts can be joined to create very large patterns Sacrificial, expendable patterns Features Functions like foundry wax and is "foundry friendly" Low residual ash content (less than 0.02%) Short burnout cycle Easy-to-process plastic Good plastic powder recycle characteristics Benefits Create complex patterns without welds or joints Reduce lead times resulting in faster time-to-market Compatible with autoclaves, low-temperature furnaces, and vacuum plaster casting methods Easy to assemble and repair patterns Rapidly test new designs in iterative process

Polymer Name: Polystyrene (unspecified)

Processing Methods: 3D Printing, Selective Laser Sintering

End Uses: Mold Making, Molds/Dies/Tools, Prototyping