Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Provides excellent flexibility

- Contains UV indicator for quality control

- Meets MIL-I-46058C, Type SR

- Compliant to IPC-CC-830B with Amendment 1

- ROHS compliant

- Flammable

- Made in USA

Applications & Uses

- Applications

- Application Area

- Applications

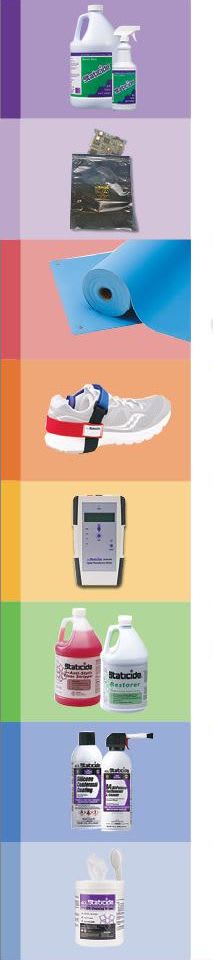

This clear coating will not fragment, chip, or crack and delivers a tough insulative barrier for PCBs, electronic assemblies, and flexible plastics. It is the go-to option for many high-end applications, such as marine, avionic, and aerospace manufacturing. Packaged in a convenient, easy-to-use aerosol spray, Silicone Conformal Coating complies with RoHS and REACH regulations.

Ideal for the following applications:

- High-end automotive manufacturing

- Marine manufacturing

- Avionics, aerospace manufacturing

- Directions

Shake well. Apply to clean and dry unmasked areas. Spray top to bottom, allowing coating to flow lightly around components. Rotate board 90 degrees and repeat. Open water vessel in drying chamber to accelerate drying.

Cure time: 1.0 mil cures tack-free in 30 minutes. Heat cures 8 hours at 170°F (76°C). Full cure requires 24 hours. Following final installation and assembly of new component, recoat area lightly. For industrial use only.

- Material Compatibility

ABS Fair Buna-N Good EPDM Good Graphite Good HDPE Good Kynar™ Fair LDPE Good LEXAN™ Fair Neoprene Good Noryl Good Nylon™ 66 Good Cross-linked PE Good Polypropylene Good Polystyrene Fair PVC Good Silicon Rubber Excellent Teflon™ Good Viton™ Good

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Operating Temperature | -64 to 199 | °C | — |

| Dielectric Strength | 1100 | volts/mil thickness | — |

| Coefficient of Thermal Expansion | 2.4x10^-4 | in/in/°C | — |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Packaging & Availability

- Packaging Information

- Product# 8695: 11 oz (312g) aerosol / 12 per case