Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- Outstanding water repellency.

- Environmentally safe and 100% vapor permeable.

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Recommendations before Beginning

- Always wear protective goggles.

- Apply a test patch of ACL 10R Sealer / Primer and ESD paint for adhesion, abrasion, resistivity and esthetics prior to coating large areas.

- Average Coverage: 250-300 sq. ft. per gallon

- For best results, seal concrete floors with ACL 10R Sealer /Primer prior to applying ESD paint.

- For best results, apply ACL 10R Sealer /Primer and ESD paint at temperatures between 60°F-80°F.

- Mix products thoroughly before using, including the ACL 10R Sealer /Primer.

- Two coats are not required, but may be preferred.

- New Concrete Floors

New concrete should cure for a minimum of thirty days before coating with ACL 10R Sealer / Primer or ESD paint.

- Clean and remove dirt/grease with detergent solution followed by a clean water rinse.

- Acid etch with muriatic acid following muriatic acid manufacturer’s directions.

- Rinse twice with warm water. Residual acid, stripper or detergent will detrimentally affect the paint adhesion.

- Test with litmus paper to ensure all the acid is removed and the floor has a neutral pH. Allow to dry 24 hours.

- Determine porosity of floor using Porosity Test found on page 3 of this manual. Very dense, non-porous or treated concrete may require additional acid treatment.

- Using a ¼” fine roller, squeegee, or airless spraying equipment, apply one coat of ACL 10R Sealer/Primer until the surface is fully saturated. ACL 10R Sealer/Primer is ready-to-use and does not need thinning. Mix thoroughly. Do not flood coat the surface of the concrete. Remove all excess primer and trapped air by stroking applicator in tray before applying to surface. Apply the correct amount to the floor allowing the primer to be absorbed by the concrete.

- Allow to dry for 2-4 hours. Check for dryness and adhesion. Use Dryness Test found on page 3 of this document.

- After floor has dried, check room and floor temperature. Do not apply paint if room and floor temperature is less than 60°F.

- Thoroughly mix paint with mixer or stirrer. This will ensure that the conductive additives are properly dispersed, allowing for proper adhesion and conductivity.

- Pour a quantity of paint in a roller tray and completely wet the roller. A ¼” cotton or polyester nap roller with a five foot extension handle is recommended. Apply paint in continuous strokes assuring complete coverage.

- Use a china white, nylon, or animal hair fine bristle brush to paint hard to reach areas and trim.

- Allow floor to dry overnight at not less than 60°F before allowing light foot traffic to resume on the surface.

- After drying, test the floor with a surface resistivity meter. If the reading is greater than 108 ohms per square and/or the readings on five separate test spots on the floor differ by more than a decade, apply a second coat of paint.

- Allow floor to dry 3 days (72 hours minimum) at not less than 60°F before allowing general industrial traffic to resume.

- Allow floor to dry 3 days (72 hours minimum) at not less than 60°F if applying optional coat of ESD floor finish. ACL dissipative floor finishes will provide an increase in gloss and durability.

- Regular Maintenance

- Allow 2 weeks of drying time after initial paint application before using a damp mop to clean coated floor.

- Sweep or dust mop daily. Use sweeper, vacuum, or an untreated mop to clean the floor. Do not use a sweeping compound.

- Damp mop weekly.

- Remove all spills immediately.

- Do not machine buff floor. Do not use abrasive cleaners or scrubbing machines with aggressive pads to clean the painted floor.

4700 Staticide® Diamond Polyurethane ESD Floor Coating may be touched up any time with additional coats. To increase gloss and abrasion resistance, apply a top coat of Staticide® Acrylic, Ultra Floor, or Ultra II Floor Finish. When using floor finish, use the maintenance instructions for the polish.

- Old Concrete Floors

- Clean and wash the floor. Apply a test patch. If the test patch is acceptable, follow the instructions under “NEW CONCRETE FLOORS” starting at step #6.

- If the test patch shows unacceptable adhesion after standing five days, proceed with the following:

- Grit sand or solvent clean the concrete to remove all embedded sealers, waxes, floor polishes, oils, greases, fluids, and chemical spills of any type. * NOTE* Consult your concrete contractor for details on proper equipment for floor sanding.

- After sanding, wash the floor with detergent and warm water then wet vacuum.

- Allow the floor to dry completely. Apply sealer/primer (following instructions) or coat of paint.

- Apply another test patch. If adhesion, abrasion, resistance and esthetics are acceptable, follow the instructions under “NEW CONCRETE FLOORS” starting at step #9.

*NOTE* Simple cleaning may be insufficient to obtain maximum adhesion of paint to old concrete floors. Prior maintenance and exposure to polyethylene wax, silicone, epoxy sealers, oil spills and other coatings or chemicals will adversely affect product performance.

Properties

- Color

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Quality Standards

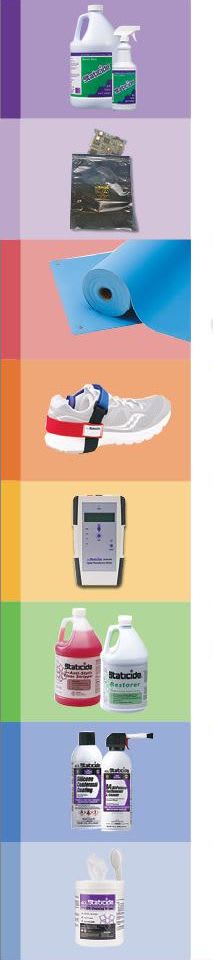

Packaging & Availability

- Packaging Type

- Packaging Information

- ACL10R-1

- ACL10R-5