Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Use

- The MBD 40161 is mainly used during the extrusion of blown film in LDPE to improve the surface appearance and decrease the phenomenon of "orange peel". It works by creating an interface between the melted polymer and the metallic surfaces of the extruder barrel and skirt. The usual recommendations are the following ones : Having made sure that all metallic surfaces coming in to contact with the polymer are thoroughly cleaned, start in low speed by adding 10% MBD 40161 and 90% base polymer. After 20 minutes adjust the extruder to full operating output speed and reduce MBD 40161 to 1 or 2 %. Exact quantity depends on machine and polymer type. A polymer containing antiblock or pigments is more abrasive, so more masterbatch is needed. This procedure of starting up must be realized after a prolonged interruption of the extruder, or after a purge with an abrasive compound. MBD 40161 is not recommended if the temperature > 240°C

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bulk Density | 0.53 | g/cm3 | ISO 60 |

| Moisture Content | max. 0.15 | % | intern |

Regulatory & Compliance

- Food Contact

- The MBD 40161 can be used for food contact applications in special conditions. For any information about the regulatory compliance, please contact the Q.S.E. department of the company.

Technical Details & Test Data

- Note

- The melt flow (according to ISO 1133) can be adapted to user demand, according to the application

- Compounds & Masterbatches

For High Performance Plastic

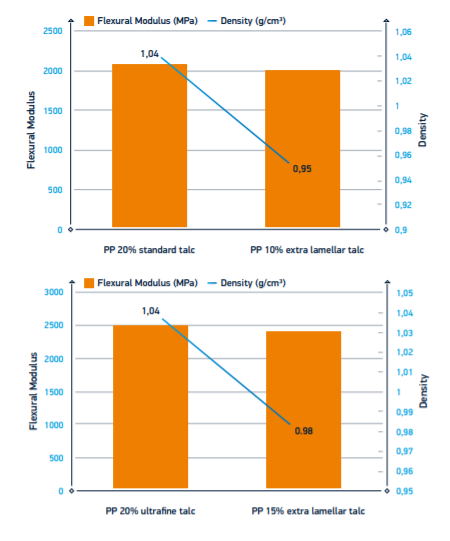

YOU WANT TO IMPROVE RIGIDITY AND HEAT DEFLECTION TEMPERATURE YOU WANT TO REDUCE WEIGHT ?

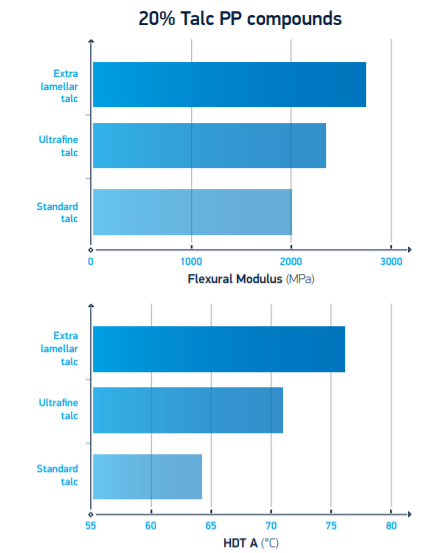

20% Talc PP compounds

Our innovative Extra lamellar Talc PP Compounds in comparison with standard and ultrafine talc.

Packaging & Availability

- Packaging Type

- Packaging

- This masterbatch is packed in PE bag

Storage & Handling

- Storage

- This must be stored protected from light and from humidity.