Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Products Highlight

- Protection from electrostatic discharges

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Physico-Chemical Properties

- Fire Resistance

| Value | Units | Test Method / Conditions | |

| Charpy Notched Impact Strength (at 23°C) | 7 | kJ/m2 | ISO 179-1/1eA |

| Hardness | 73 | Shore D | ISO 868 |

| Charpy Unnotched Impact Strength (at 23°C) | NB | kJ/m2 | ISO 179-1/1eU |

| Elongation at Break | 4 | % | ISO 527-2/1A |

| Flexural Modulus | 1200 | MPa | ISO 178 |

| Izod Notched Impact Strength | 7.5 | kJ/m2 | ISO 180/1A |

| Stress at Break | 20 | MPa | ISO 527-2/1A |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature | 55 | °C | ISO 75-2/Af |

| Melting Point | 165/168 | °C | ISO 11357-3 |

| Vicat Softening Point | 150 | °C | ISO 306/A50 |

| Value | Units | Test Method / Conditions | |

| CTI | 50 | V | CEI 60112 |

| Surface Resistivity | 102-104 | Ω-square | CEI 60093 |

| Value | Units | Test Method / Conditions | |

| Density | 0.99 | g/cm3 | ISO 1183-1 |

| MVI (at 230°C-2.16Kg) | 30 | cm3/10min | ISO 1133-1 |

| Value | Units | Test Method / Conditions | |

| Falling Ball Test | 127 | °C | CEI 60695-10-2 |

Technical Details & Test Data

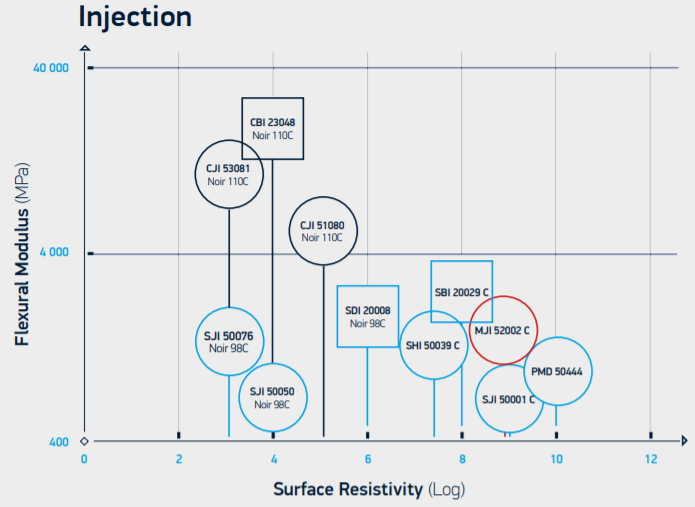

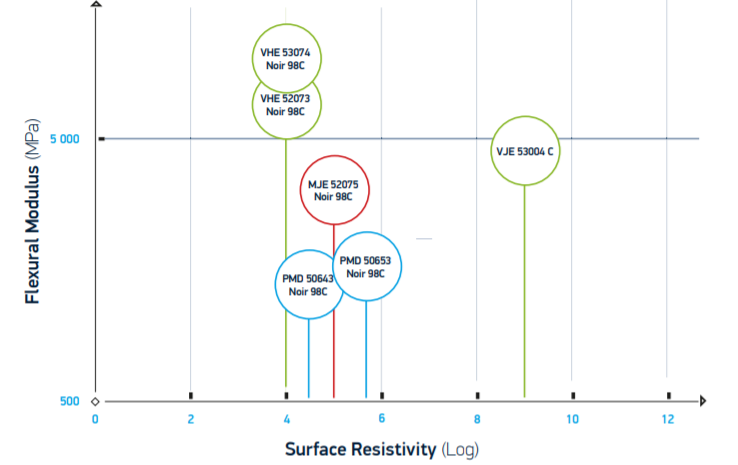

- Protection from Electrostatic Discharges

ESD & Semi-conductive Compounds

Natural compounds can be colored

Extrusion

- Glass fiber compounds

- Mineral fi lled compounds

- Unfilled compounds

- Note

- The LOI measures are obtained through standard specimens of type I, with ignition of type A.

- The values indicated above have been realized with standard specimens which are conditionned according to ISO 291. These datas must be considered as indicative values, but in no case as minimum values. Moreover, the design of the mold/die, the processing conditions and the color may have an impact on the properties.