Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

"ANTI-HYDRO"-NC is a non-chloride solution of organic and inorganic chemicals that reacts with portland cement to produce more complete hydration. Water requirements, bleed water, capillaries and shrinkage are reduced. The increased hydration providesinternal curing and paste that binds the aggregates together. These combined reactions produce impermeable mortar that is hard, non-dusting and durable. It enhances intensity and durability of color. "ANTH-HYDRO-NC" is suitable for use with potable water and is compatible with subsequent finishes. much denser, harder and tougher cement

Applications & Uses

- Markets

- Mix Design

Pre-packaged mortars shall be Type M and/or Type S only as defined by ASTM C 270 Table 2. Field mixed mortars shall be proportioned as follows:

Type M Cement 94 Lb. (1 Bag) 1 cu.ft. Lime 1 Lb. 0.25 cu. ft. Sand 240 Lb.=3 cu.ft Type S Cement 94 Lb. 1 cu. ft. Lime 20 Lb. 0.5 cu. ft. Sand 360Lb. 4.5 cu. ft. Field mixed mortars may be made without lime. Portland cement shall be Type-1/Type2 and sand shal conform to ASTM C 144. Gaging liquid shal be a blend of 1 part "ANTI-HYDRO-NC" and 15 parts water. All parts measure by volume. Add enough gaging liquid to produce a workable mix

- Applications

All brick or masonry units shall be thoroughly wet before laying (except in freezing weather) and bedded in mortar under the entire surface. Push-lay all brick. The compaction achieved by tooling joints gives greater density and bond.

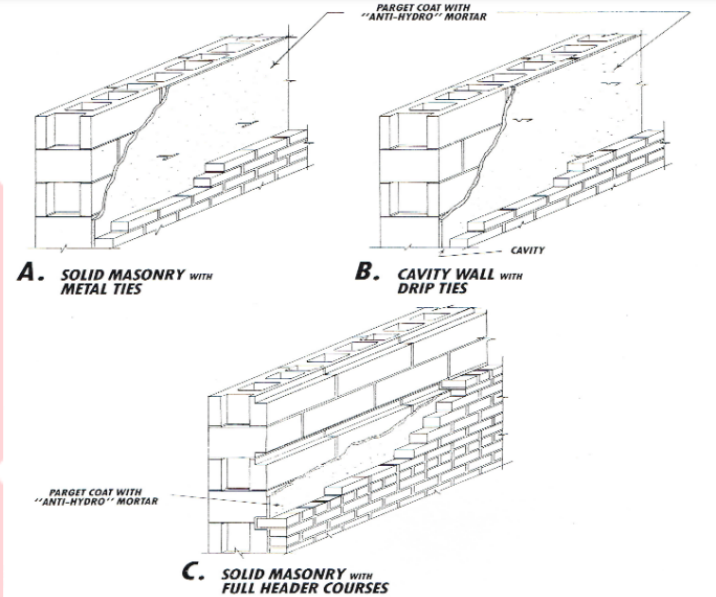

For solid masonry walls, a complete mortar parget coat shall be applied between back-up masonry and the brick veneer. If header courses are used, pargeting shall be continuous around the headers.

For cavity wall construction, the parget coat shall be applied to the back-up masonry. Provide proper weep holes and flashings in exterior brick work.

Technical Details & Test Data

- Typical Properties / Performance Data

Concrete/mortar specimens, with "Anti-Hydro®” admixture, tested by various independent laboratories has shown:

Impermeability/Waterproofing- Impermeable" at 20 psi (26 head of water)

Vapor Transmission/Dampproofing- Produced 85% reduction in transmission of vapor.” ACI 318/Non-Corrosive- Greatly exceed the requirements (noncorrosive].*# No sign of steel corrosion in concrete with “Anti- Hydro®

Durability- Highest durability (overa 15 year, freeze/thaw,

durability test) of any material tested.”

Integral Curing- Concrete cured internally, survived durability \tests of 719 freezing-thawing cycles withaut any damage.** \ Acceleration: High range accelerator." 30% reduction in concrete setting times at 322 F.>

High Strength/Compressive Strength- Concrete showed

compressive strength significantly higher at all ages.""* Concrete exhibited 2796 increase in 3 days and 23% in 7 days.* Mortar exhibited 1436 inerease in 1 day, 1158 in 3 days and 1296 in7 days.”

Abrasion Resistance: Produced 85% increase in abrasion resistance10."

Shrinkage Reduction- 20-25% reduction in shrinkage6.”

Shrinkage Reduction- 20-25% reduction in shrinkage6.”

Plasticity- Produced a 29% increase in plasticity.”

ASTM Spetification- Meets ASTM C-494, Types A, C & E

* The above labatory results May Very Dependent real Field Conditions.- Technical Details

Safety & Health

- Safety

Use approved Saftey glasses, rubber gloves, coveralls and work boots. Protect animals , Vegetation an food items

- Maintenance

All due diligence must be exercised to provide a regular and frequent maintenance plan to clean and’protect finished surface from severe or prolonged assault Irom»chemical attack, abrasive atttack Similiar abuse.

Packaging & Availability

- Packaging

‘A-quart, 1-gallon, 5-gallon, 55-gallon or 220-gallon containers,

ESTIMATOR’S DATA GUIDE:

1 quart of " Anti- Hydro®"-NC Per bag (94Lb) of Type-1/Type-2 Portland Cement

Guaging Liquid- 1 Part of Anti- Hydro®"-NC to 15 parts of Water. Parts are Measured by Volume

5-51/2 Quarts of Guaging Liquid per 80Lb. of Type M and / or Type S Mortor Only (pre-packaged)

Storage & Handling

- Storage

Store in dry, cool place. Keep Containers tightly closed. Keep Away From Children