Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Dragonite™-XR in Polyethylene

DRAGONITE-XR performs as loadings are increased and around 60 weight % it imparts halogen free flame retardance on top of reinforcement through the modulus and strength benefits.

- Dragonite™-XR in Polylactic acid (PLA)

For higher addition levels, Dragonite-XR is the preferred solution bringing not only further reinforcement through improvements to modulus and strength but also with the added advantage of flame retardance up to V0 level.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

Properties

- Typical Properties

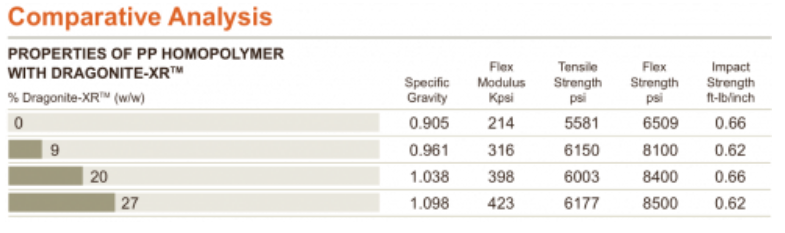

- Dragonite™-XR in Polypropylene

In PP homopolymer Dragonite-XR delivers great properties at low density. Reinforcement is obtained, as indicated by the improvement in flexural strength and modulus, even without the use of coupling agents. This is attributed to the high aspect ratio of the filler combined with good wetting of the filler surface. Further evidence of excellent dispersion can be seen in the impact resistance, which is preserved at all loadings. The ability of DRAGONITE-XR to provide attractive properties at high loadings makes it an appealing alternative to traditional mineral flame retardants.

- Dragonite™-XR in Nylon 6

Higher levels of Dragonite-XR grade result in substantial reinforcement as seen by the simultaneous improvement in modulus and strength. Unlike traditional reinforcing agents, Dragonite-XR enables good retention of impact resistance and low weight because of the low density of the filler. At even higher loadings a V0 flame retardance rating is possible.

Property Control Nylon 6 4% Dragonite™-XR 8% Dragonite™-XR 14% Dragonite™-XR 19% Dragonite™-XR 27% Dragonite™-XR Flexural Modulus (Kpsi) 398 521 539 671 700 891 Flexural Strength (psi) 14785 18428 18351 20272 21041 21817 Impact Resistance (ft-b/inch) 1.2 0.94 0.90 0.95 0.94 0.93 Density (g/cm3) 1.130 1.160 1.186 1.226 1.262 1.317

| Value | Units | Test Method / Conditions | |

| pH | 5 - 7 | — | — |

Technical Details & Test Data

- Dragonite™-XR in a wide range of resins

Plastic Type Nucleation/ Cycle Time Reduction Clear Film PE Yes Yes PP Yes Yes EVA TBD Yes PA6 TBD TBD PA12 Yes TBD PVC TBD Yes PLA TBD TBD Epoxy TBD TBD EPDM TBD TBD Suggested Grade Dragonite™-XR Dragonite™-XR