Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Components

(2) Part A - Epoxy/Silver Part B - Hardener/Silver

- Consistency

Viscous, Thixotropic Paste

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Cure Method

- Applications

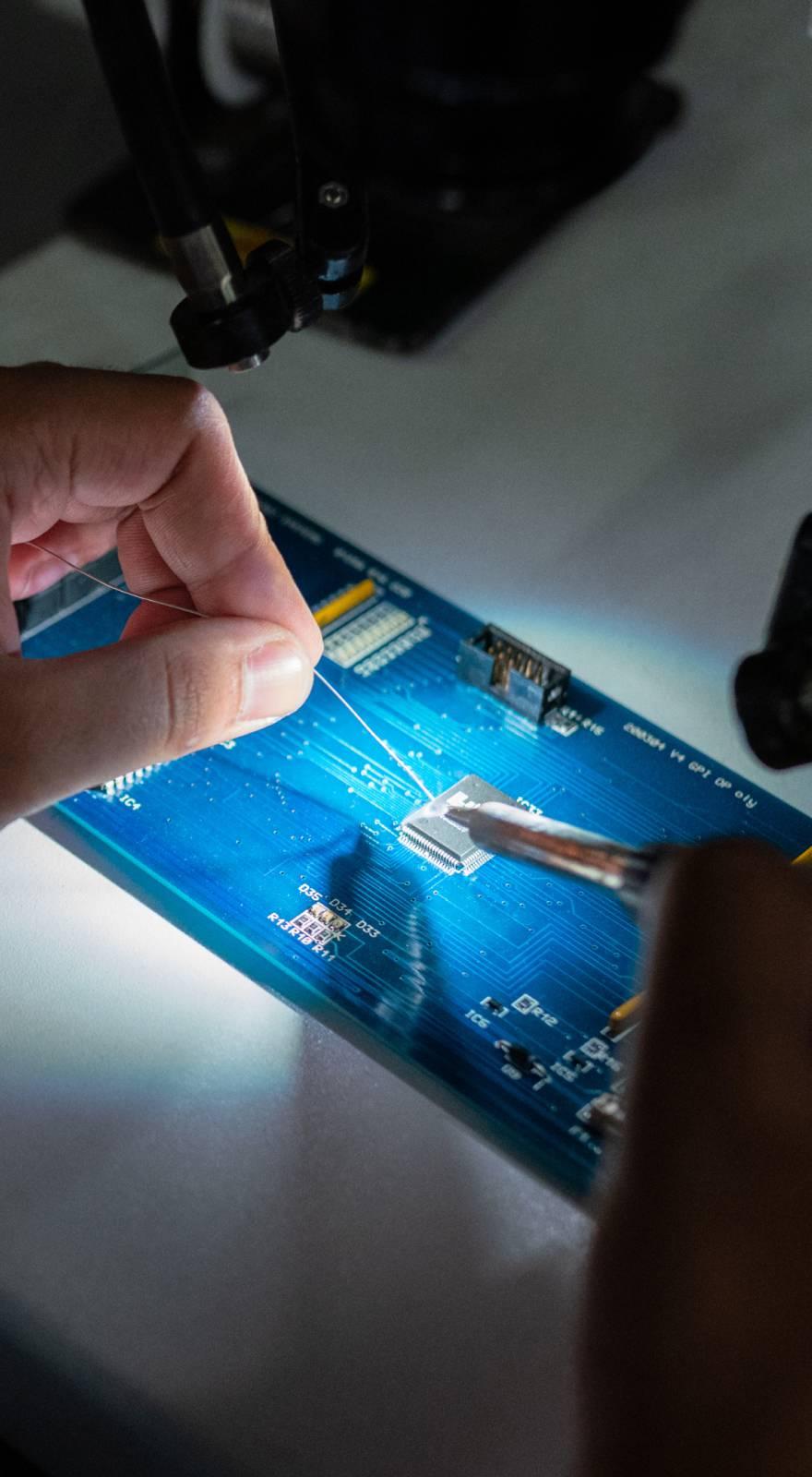

- Making/repairing flexible circuitry

- Chip bonding

- Die attachment

- Solderless wire connections

- Repair of automotive rear window defogger and antenna circuits

- Instructions

- Be sure that all surfaces to be bonded or coated with 5922 silver epoxy are clean, dry, and free of any grease or oil.

- Thoroughly mix equal amounts (by weight or volume) of Part-A and Part-B. Typical mixing times for small batches up to 5 grams is approximately 2 minutes.

- Since 5922 silver epoxy is designed to be cured at room temperature or with low heat, it is recommended that applications be made within 30 minutes of mixing. After this time the material will exhibit drastic increases in viscosity

- For cleanup of uncured material use isopropyl alcohol.

- Curing Schedule

24-48 Hours at 25°C or 15 Minutes at 80-100°C

- Mix-Ratio

1:1 (by weight or volume)

- Pot Life

30 minutes at 20-25°C for a 3-5 gm mass

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Silver Content | 85.0 | % | - |

| Specific Gravity | 4.1 | - | - |

| Volume Resistivity | max. 0.001 | ohm-cm | - |

| Thermal Conductivity (in/F² hr °F) | 10.0 | BTU | - |

| Tensile Lap Shear | min. 800 | psi | - |

| Service Temperature Range | -55 - (+)80 | °C | - |

Storage & Handling

- Shelf Life

Three months at room temperature (25°C), unmixed