Knowde Enhanced TDS

Identification & Functionality

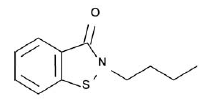

- Chemical Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 4299-07-4

- EC No.

- 420-590-7

- Product Families

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Industrial Additives End Use

- Plastics & Elastomers End Uses

- Applications

VANQUISH 100 Antimicrobial can be used to preserve PVC, silicone, polyolefin, polyurethane and acrylic articles such as:

- Shower curtains

- Coated fabric (e.g. ski wear, raincoats, tents etc.)

- Vinyl wall coverings, floor coverings, underlay & mats

- Swimming pool, pond and ditch liners

- Conveyor belts

- Shoe soles and mid-soles

- Roofing membranes

- Auto parts (e.g. vinyl roofs, door seals, shock absorbers,

- steering wheels etc.)

- Foam (e.g. seat cushions, gaskets, insulation etc.)

- Electrical & pipe wrap

- Appliance gaskets such as washers, refrigerator etc.

- Tarpaulins and awnings

- Wall and floor coatings

- Use Guidelines

VANQUISH 100 Antimicrobial may be used for the manufacture of liquid or solid antimicrobial formulations. VANQUISH 100 Antimicrobial may also be used for direct incorporation into plastics or their precursors to preserve plastic articles from microbial degradation.

The activity of the product has been further demonstrated under conditions representative of practical use. However, it is recommended that you carry out tests under practical conditions to determine the most cost-effective dose for your application.

This data, and information on the compatibility of VANQUISH 100 Antimicrobial with a range of formulating chemicals is available on request.

Incorporation of VANQUISH 100 AntimicrobialPVC Plastisols: For addition to PVC plastisols VANQUISH 100 Antimicrobial may be added along with the other additives. Use levels should be calculated based upon the total weight of the formulation.

PVC: VANQUISH 100 Antimicrobial may be added to the mixed liquid components, added to a blend of PVC resin and solids, shear mixed until a dry blend is achieved and then processed through extrusion, calendering, molding or other system.

Cross Linked Polyurethane: For addition to crosslinked polyurethanes, VANQUISH 100 Antimicrobial should be added to the polyol at a concentration that will yield the desired use level in the final product after reaction with the isocyanate component.

Melt Processed Polymers: For addition to melt processed polymers (PVC, thermoplastic polyurethane, synthetic elastomers and thermoplastic acrylics etc.) VANQUISH 100

Antimicrobial may be metered into the melt to yield the desired end use concentration (e.g. at the mixing zone in an extrusion system).Alternatively, VANQUISH 100 Antimicrobial may be made into a masterbatch granule (as above at up to 20% VANQUISH 100 Antimicrobial) and the masterbatch blended with non preserved polymer in the users plant to yield the desired end use concentration upon subsequent melt processing. For thermoplastic polyurethanes, concentrated granules may also be produced by absorbing VANQUISH 100 Antimicrobial liquid into granules through shear mixing (up to 20% VANQUISH 100 Antimicrobial).

These can be blended with non-preserved polymer granules in the users plant to the desired use concentration and then further melt processed (i.e. via extrusion).

Acrylics: In addition to the above, VANQUISH 100 Antimicrobial can be added to the liquid monomers before polymerization, at levels to yield the desired use level in the final product after polymerization.

Natural Rubber: VANQUISH 100 Antimicrobial can be added to the latex.

Polyolefins: VANQUISH 100 Antimicrobial may be made into a masterbatch granule (up to 5-10% VANQUISH 100 Antimicrobial).- Application Information

Application Concentration (% based on total weight of final product) Plasticized PVC 0.03 to 0.5 Polyurethanes 0.05 to 0.5 Polyesters 0.05 to 1.0 Polyolefins 0.05 to 1.0 Acrylics 0.05 to 1.0 Synthetic elastomers such as

butadiene-styrene, styrene-isoprene and acrylonitrile-butadiene-styrene0.03 to 1.0 Natural latex rubber 0.03 to 0.5 The concentration required to give protection depends on several factors. These include the susceptibility of the system to microbiological degradation, the extent to which micro-organisms can gain access, the species involved, pH, temperature, moisture and length of time for which protection is required.

Properties

- Physical Form

- Odor

- Mild or none

- Typical Physical Properties

- Antimicrobial Properties

The efficacy of the product was evaluated by the calculation of Minimum Inhibitory Concentrations (MICs) [Table 1]. MICs do not represent effective use levels but do indicate the intrinsic broad spectrum of antimicrobials. VANQUISH 100 Antimicrobial has a non-specific mode of biocidal action which means that bacterial resistance is very unlikely to occur.

- Compatibility

- The active ingredient BBIT is incompatible with thiols,bleach and metabisulphites.

- Minimum Inhibitory Concentrations (MIC)

Table 1:

Micro-organism ppm product Fungi Alternaria alternata 25 Aureobasidium pullulans 4 Aspergillus niger 16 Chaetomium globosum 1.6 Cladosporium cladosporoides 19 Cladosporium herbarum 2.3 Gliocladium virens 62 Paecilomyces varioti 4 Penicillium funiculosum 3 Phoma violacea 2 Scopulariopsis brevicaulis 37 Trichoderma viride 50 Algae Chlorella vulgaris 16 Nostoc muscorum 16 Oscillatoria tenuis 16 Pleurococcus sp. 16 Trentepohlia aurea 16 Bacteria Acinetobacter baumanii 14 Bacillus cereus 2 Bacillus subtilis 2 Enterobacter cloacae 125 Enterococcus faecalis 2 Enterococcus hirae 4 Escherichia coli 62 Klebsiella pneumoniae 15 Listeria monocytogenes 4 Proteus mirabilis 125 Proteus rettgeri 125 Proteus vulgaris 60 Pseudomonas aeruginosa 125 Pseudomonas cepacia 60 Pseudomonas fluorescens 60 Serratia marcescens 250 Salmonella typhimurium 8 Staphylococcus aureus 2.5 Yersinia enterocolitica 15 Streptomycetes Streptoverticillium waksmanii 2 Yeast Candida albicans 19 Rhodoturula mucilaginosa 4 Saccharomyces cerevisiae 0.4

| Value | Units | Test Method / Conditions | |

| Active Agent Content | min. 97 | % w/w | — |

| Brookfield Viscosity (3 at 20°C) | 90 | cP | LV spindle 3 |

| Density | 1.17 | g/ml | — |

| Flash Point | 178 (+/- 5) | °C | — |

| Vapour Pressure (at 25°C) | 0.015 | Pa | — |

| Water Content | max. 0.5 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Regulatory Information

The components of VANQUISH 100 Antimicrobial are in compliance with the following inventories:

- ELINCS - (European Union)

- AICS - (Australia)

- ENCS - (Japan)

- KECL - (Korea)

- PICCS - (Philippines)

- IECSC - (China)

Safety & Health

- Health And Safety Information

The VANQUISH 100 Antimicrobial Safety Data Sheet may be supplied upon request. It should be read and understood by all supervisory personnel and employees before using this product.

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage Stability

- Stable under normal conditionsof storage.