Knowde Enhanced TDS

Identification & Functionality

- Ingredient Origin

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- What it is and how it works

QUIDEX ® 3.2 is a disruptive innovation that revolutionizes the perfume manufacturing process, transforming a slow, high energy-consuming, expensive and inefficient process into a fast, lean, simple and easy way to produce high quality perfumes.

What it is?

QUIDEX® 3.2 is a patented technology based on the combination of highly reactive biopolymers from botanical origin and mesh-forming molecules.

How does it work?

QUIDEX® 3.2 reacts with contaminants and undesirable components of the alcoholic solution, accelerating the aging (maceration) process by removing selectively the volatile substances responsible for blocking the olfactory receptor cells.

Type of Perfume Fragrance dosage Traditional macerations in Days/Hours With QUIDEX® 3.2 Parfum 20 - 25% 30 days 15 minutes Eau de Parfum 12 - 18% 20 days 15 minutes Body Splash 5 - 8% 5 to 8 days 15 minutes - Advantages and Benefits

Advantages of Adopting the Quidex® 3.2

- Immediate results with just a 0.5 % dosage

- Easy to incorporate into the hydroalcoholic solution

- Easily removed by filtration

- Easy to handle, transport and stock

- Free from preservatives

Benefits of Adopting the Quidex® 3.2

- QUIDEX® 3.2 is effective at very low concentrations

- QUIDEX® 3.2 provides instant maceration

- QUIDEX® 3.2 dramatically reduces processing time

- QUIDEX® 3.2 increases the productivity of existing factory by up to 30 times

- QUIDEX® 3.2 reduces the need for investment in new equipment (chillers and tanks).

- QUIDEX® 3.2 improves the response capacity in a case of non-budgeted sales

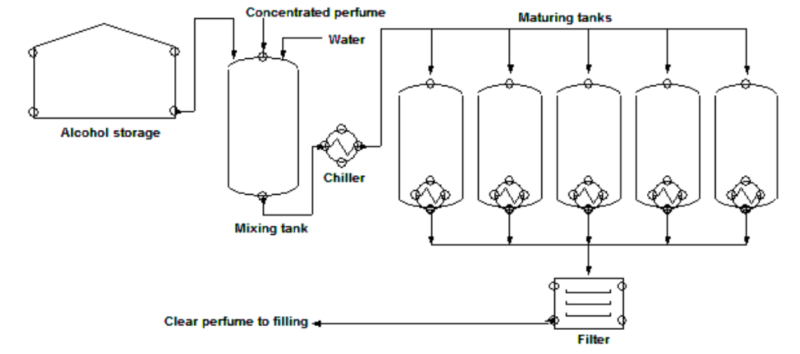

Conventional Process

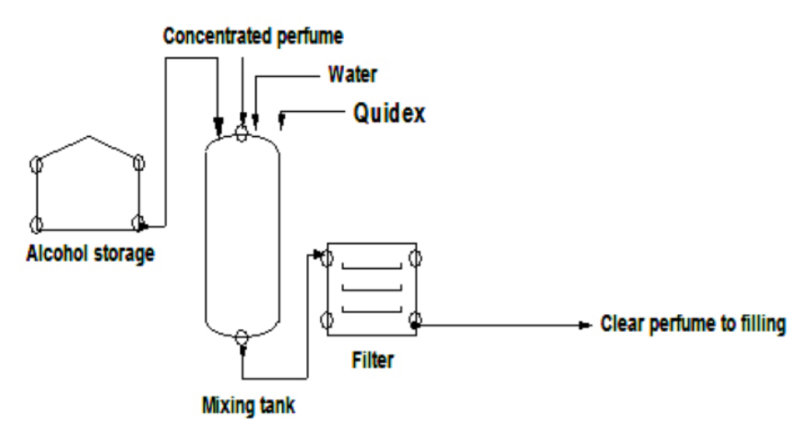

QUIDEX® Process

- Traditional Process and Critical Points

- Prepare solution of alcohol + water

- Add fragrance

- Mix well

- Age/macerate

- Cool

- Filter

- Pack

AGING

aging = time (days, weeks, months!)

time = money

aging = cost

aging ⇑ = cost ⇑COOLING

cooling = time (hours)

cooling = equipment

cooling = energytime, chillers and energy = cost

FILTERING

filtering = time (hours)

filtering = supplies (paper, cartriges)

filtering = rework (if the filtering product is still hazy)time, supplies and rework = cost

- INVENTORY COSTS: you have to keep high inventories of “unfinished product” in stock

- INSURANCE COSTS: more tanks with alcohol in the plant = higher risks = higher insurance costs

- WORKING CAPITAL COSTS: you have to wait “X” days before you are able to sell your product (or collect $$ from your client, if you are a contract manufacturer)

- SALES: if your sales planning is poor or inaccurate or cannot react to any unexpected sales budget. You simply miss the chance – and the money, because the new batch is still aging…

- INVESTMENTS: if you need to expand your production capacity tanking will be an issue. Tanks cost money and need plant space.

- You Will Need

- QUIDEX® 3.2

- Alcohol and water

- Fragrance

Steps:

- Mix alcohol and water.

- Add fragrance to the mixture.

- Add QUIDEX® to the mixture and stir.

- Mix well for 2 to 3 minutes and filter.

- Filtration

- Residue after filtration.

- Final product: crystal clear liquid.

Applications & Uses

- Fragrances & Perfume Applications

Properties

- Physical Form

Technical Details & Test Data

- Disruptive Innovation

Disrupting Fine Fragrance Maceration

Brazilian company Assessa is disrupting the time consuming and costly process of fine fragrance creation with QUIDEX® 3.2. Shani Vermeulen from Cosmetic Ingredients shares insight into this processing aid.

Fine fragrance production starts with the creation of the fragrance, which is added to a blend of ethanol and water and yielded to a time-consuming aging process known as maceration. This consists of three steps: aging; cooling and filtering.

Fragrance ingredients often contain unwanted by-products such as waxes, steroids and paraffins. Volatile substances like acetaldehydes overpower the olfactory cells and affect fragrance perception. When the fine fragrance concentrate is added to the polar blend of ethanol and water, the non-polar impurities form a stable suspension of very fine particles. The blend can, during maceration, undergo chemical changes that could affect the perception of the fragrance. The new molecules that form are less volatile and do not interfere in the perception of the fragrance’s more subtle notes. Traditionally, the undesired particles that precipitate can be removed by keeping the blend chilled for a few days up to several weeks before filtering out the particles to achieve the crystal clear finished fragrances we see on retail shelves.

Like a fine wine must age to improve its taste – a fine fragrance has to macerate. The aging process can take anything from a few days up to a few weeks and time equals money. Aging tanks are costly and take up floor space. The inventory costs are high while tanks filled with flammable liquid pose a fire risk, leading to increased risk and higher insurance costs. While fragrances age, working capital is restricted. Should a certain fragrance sell unexpectedly well and stock runs low, sales opportunities can be missed while the new batch is still aging.

The energy needed to cool fragrances down to the required temperature is also expensive. The time the fragrances are kept at this temperature adds to the costs.

Once aging and chilling are completed, the fragrance is filtered. If tiny particles still cloud the fragrance, the entire maceration process has to be repeated.

Time-Saving Innovation

Time-saving innovation QUIDEX® 3.2 powder is a disruptive innovation that, as little as 0.5 percent, saves fragrance manufacturing costs by transforming maceration into a hazard-free, time- and energy-saving process. The patented technology is based on the combination of highly reactive, sustainable biopolymers and mesh-forming molecules.

QUIDEX® 3.2 is neither a fixative nor a booster ingredient. It is a powder that reacts instantly with contaminants and undesirable volatile components (which block the olfactory receptor cells) in the alcoholic blend, thereby accelerating the maceration process.

Even if a manufacturer does not macerate, the benefits can be perceived in that the biopolymers immediately remove the volatile notes and impurities from the hydroalcoholic blend so that the pure fragrance scents can be perceived immediately.

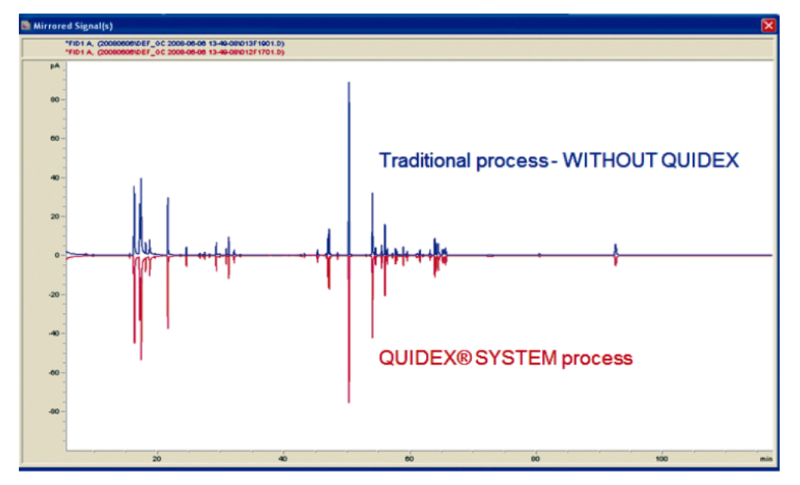

Because it is not a cosmetic ingredient, but a processing aid, QUIDEX® 3.2 does not have an INCI name. By using this powder innovation, the entire maceration process can be performed at room temperature. QUIDEX® 3.2 does not remove any fragrance component; it also doesn’t alter the olfactory properties, which has been chromatographically proven for hundreds of fragrances. Trained perfumers and evaluators agreed they could not detect any significant difference when comparing fragrances processed with this new technology versus those processed using traditional maceration technology.

- FAQ

I DO NOT MACERATE. HOW CAN QUIDEX® 3.2 HELP ME?

QUIDEX® 3.2 provide an instant effect on the hydro alcoholic solution removing volatile notes and impurities, resulting in a crystal clear solution. The scents are perceived immediately. You’ll get high quality perfumes with instant maceration – without the time and cost involved in a traditional process.

DO I NEED TO CHANGE MY LABELS AND LEGAL REGISTERS?

NO.

QUIDEX® 3.2 is completely removed from the solution after the filtration process. No residue is detected in the finished product.

QUIDEX® 3.2 shall be considered as a production process, equivalent to a filter aid.

DOES QUIDEX® 3.2 AFFECT THE FRAGRANCE PERCEPTION?

NO.

Hundreds of fragrances were tested by trained evaluators and perfumers and no significant difference could be detected in any sample.

DOES QUIDEXO 3.2 AFFECT THE COMPOSITION OF THE PRODUCT?

NO.

QUIDEX® 3.2 does not remove any component of the fragrance and doesn’t change its olfactive characteristics. Hundreds of fragrances were already tested (chromatography) and no difference can be detected in any sample.

DOES QUIDEXO 3.2 HAVE AN INCI NAME?

NO.

QUIDEX® 3.2 is not a cosmetic ingredient, since it is completely removed from the solution.

DO I NEED TO COOL THE SOLUTION BEFORE FILTRATION?

NO.

With QUIDEX® 3.2 you don’t need to cool the solution. The whole process is carried at room temperature.

CAN I FILTER THE SOLUTION IMMEDIATELY AFTER ADDING QUIDEXO 3.2 TO THE FRAGRANCE?

Yes

SHALL I USE THE SAME FILTERS THAT I ACTUALLY USE TO REMOVE THE INSOLUBLES FROM TE SOLUTION?

YES.

You can use the same filters.

PIGMENTS, SUNSCREENS, ANTIOXIDANTS, SOLUBILIZERS OR ANOTHER INGREDIENT MUST BE ADDED BEFORE OR AFTER THE FILTRATION PROCESS?

All additives must be added after the filtration of the floccules formed by QUIDEX® 3.2.