Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CAS No.

- 2361055-93-6

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Fluids & Lubricants Features

- Benefits

- Unparalleled lubricity

- Provide superb wear protection

- Are free of restricted chemicals

- Vegetable derived

- Excellent hydrolytic stability

- Natural detergency

- Improves overall operations in terms of uptime

- Minimizes safety risks

- Reduces overall formulation cost

- Meet the national chemical inventory requirements

- Increases operational efficiency

- Reduces cost related to maintenance

- Are REACH registered

- HX1 certified

- Show no signs of dermal irritation

- Naturally low foaming

- Environmental Performance Data

- High Biodegradability

- Low Bioaccumulation

- Low Toxicity

- High Bio-Content

- Rapid Breakdown

- No dermal irritation

- Low Environmental Risk

- Reduced Risk to Wildlife

Applications & Uses

- Markets

- Compatible Base Stocks

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Applications

- Biocea additives are used in a variety of metalworking and metal forming fluid formulations for all 4 major classes of metalworking fluids: straight oil, soluble oil, semisynthetic, and synthetic metalworking fluids.

- Biocea additives can be used as high-performance lubricity additives, that meet (and often exceed) the technology requirement needed in modern machining techniques.

- Biocea additives are considered to be the best biobased choice for multi-purpose or general-purpose applications in neat oils, soluble oils, and semi-synthetic fluids. They have good solubility in all base oils, and easily emulsify in water-based chemistries.

Properties

- Physical Form

- Environmental Properties

- Specifications

- Note

*Numbers are based on industry averages and final numbers for individual products may vary. Results listed in the table may vary. Optimum blends can be created to maximize performance.

| Value | Units | Test Method / Conditions | |

| Bio Content | min. 80 | % | ASTM D6866 |

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 1500 | — | — |

Regulatory & Compliance

Technical Details & Test Data

- Technical Performance Data

Biosynthetic Technologies Biocea additives provide excellent lubricity, film strength, and improved tool life when compared to other lubricity additives. In addition to superior oxidative stability, Biocea additives provide excellent wear protection as well as industry-leading hydrolytic stability. Below, please find the ranking for the leading metalworking fluid additives performance features, and see how Biocea additives outperform the most commonly used additives available in the market today.

Performance Feature Biocea™ II Lubricity ✓ ✓ Film Strength ✓ ✓ ✓ Anti-Wear ✓ ✓ ✓ Improved Tool Life ✓ ✓ Increased Polarity ✓ ✓ Hydrolytic Stability ✓ ✓ ✓ - CADRE Method

Biocea additives have been evaluated through a revolutionary new method known as the CADRE Method. This is a new innovative modeling software used to safely determine skin sensitization concerns without requiring any animal testing. Biocea additives show no signs of dermal irritation or allergic sensitization. The lack of odor and skin irritation make these additives extremely suitable for metalworking fluid applications while promoting a safe work environment.

Pass Method Biocea™ II Biodegradability OECD 301B Readily Toxicity OECD 201, 202, 203, 209 Pass - Biocea™ Twist Compression Test

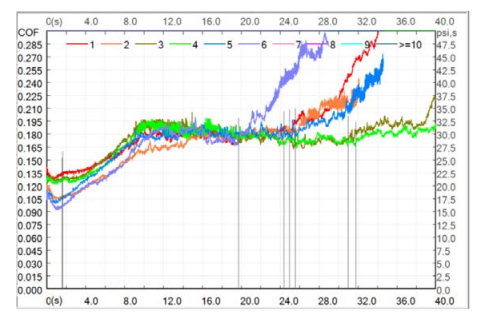

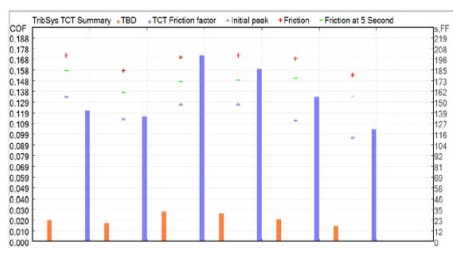

During initial testing the Biocea™ products indicated superior performance when comparted to traditional technology currently available in the marketplace. Overall, the Biocea™ IIIHP (15%) showed superior performance.

Packaging & Availability

- Packaging Type