Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Highlights

- Enhances Flexibility

- Provides Hardness & Strength

- Exhibits Hydrolytic Stability

- Abrasion Resistant

- Non-Yellowing

- Gloss Finish

- Improves Weatherability

Applications & Uses

- Applications

- Flexible hard coatings

- Plastics adhesives

Properties

- Typical Properties

- Cured Properties

- Uncured Properties

| Value | Units | Test Method / Conditions | |

| Fluorescing | Ultra-Red | - | - |

| Rheology | Newtonian | - | - |

| Value | Units | Test Method / Conditions | |

| Durometer Hardness | D60 | - | - |

| Elongation at Break | 170.0 | % | - |

| Glass Transition Temperature (Tg) | 22.0 | °C | - |

| Modulus of Elasticity | 641 [93,000] | MPa (psi) | - |

| Nominal Viscosity | 1200.0 | cP | - |

| Tensile at Break | 2,100 | psi | - |

| Value | Units | Test Method / Conditions | |

| Density (25°C) | 1.15 | g/cm³ | — |

| Pt-Co Color (APHA) | 50.0 | - | - |

| Refractive Index (25°C) | 1.492 | - | - |

| Viscosity | 34000.0 | cP (at 20 rpm) | - |

| Viscosity at 25°C | 35000.0 | cP | - |

Technical Details & Test Data

- Typical Formulations

Adhesion Properties Substrate I30 I50 TM50 TP50 H50 HE30 ABS XXX XXX XXX XXX XXX XX Aluminum Cold Rolled Steel

X XX Glass X HDPE PET XXX XXX XXX XXX XXX XX PMMA XX XXX XXX XXX XX X Polycarbonate XX XXX XXX XXX XXX X Polypropylene X PVC XXX XXX XXX XX XXX X Stainless Steel XXX XX X Recommended XX Highly Recommended XXX Strongly Recommended

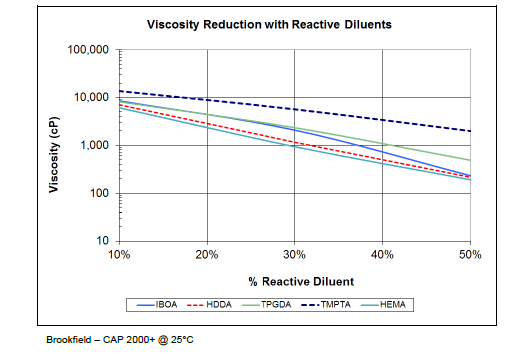

Typical Formulations Test Formulation Name 130 150 TM50 TP50 H50 HE30 BR-742M 70 50 50 50 50 70 IBOA 30 50 TMPTA 50 TPGDA 50 HDDA 50 HEMA 30 Omnirad 184 2 2 2 2 2 2 Viscosity, 25°C* 2,100 420 2,000 480 220 940 Brookfield – CAP 2000+ @ 25°C.

Cured Mechanical Properties Property I30 I50 TM50 TP50 H50 HE30 Tensile Strength, psi**

2,100 4,100 5,000 1,500 2,300 700 Elongation, 6** 40 65 4 12 10 35 Elastic Modulus, ksi*

9.5 140 220 35 70 25 Durometer Hardness

61D 80D 86D 74D 77D 44A Water Absorption, 96 (24 hrs)

0 0.28 0.45 1 0 2 MEK Double Rubs (#)

30 20 >200 64 >200 25 Tg(DMA)=29°C; Peak tan delta; cured with 2 phr of Omnirad® 184 ** Per ASTM D882 – Not Tested || Incompatible X Unable to Measure

- Viscosity Reduction With Reactive Diluents

Safety & Health

- General Information

This product is intended for industrial use only. Keep out of the reach of children. Avoid breathing vapors. Avoid contact with skin, eyes, and clothing. Wear impervious gloves. Repeated or continuous skin contact with uncured material may cause irritation. Remove material from skin with soap and water. Never use organic solvents to remove material from skin and eyes. For more information on the safe handling of this material, please refer to the Safety Data Sheet before use.