Knowde Enhanced TDS

Identification & Functionality

- Backing Material Type

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Areas Of Application

Sealing and insulation of pipes:

- In building construction

- In industry

- In air-conditioning technology

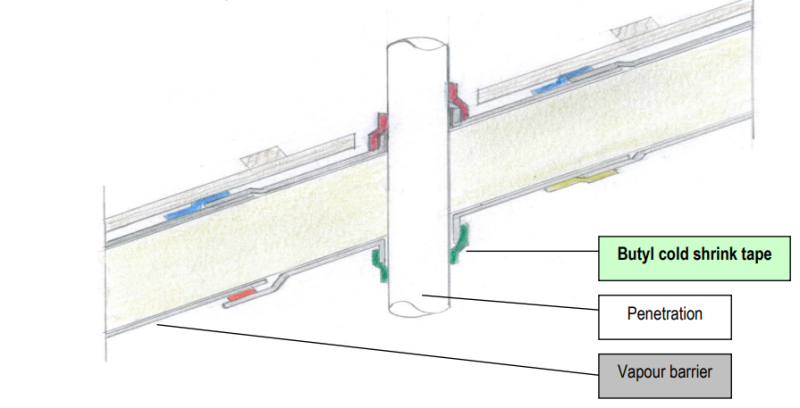

Roofing seals: sealing vapor barriers in penetrations

When using as a water-protective seal, ensure that there is no possibility of standing water accumulating on the sealing tape. Butyl cold shrink tape is meant for indoors; we recommend our aluminum or lead butyl tapes for outdoors.

- Processing

The surface must be stable, clean, dry and dust-, grease- and oil-free. Pre-coat brittle, porous and absorbent surfaces with our Multi Primer. Check the underground for compatibility beforehand. Before application check, whether the butyl rubber adhesive is compatible with the underground regarding adhesive strength and chemical compatibility. The adhesive tape is applied spirally and overlapping, e.g. onto pipes. For this purpose remove the backing from the adhesive, attach the tape to the pipe and then wind around the pipe under tension in such a way that no bubbles develop between the butyl rubber adhesive and the underground. Then press the tape firmly onto the underground and smooth. Butyl rubber adhesives are long-term ductile and non-flexible. They are not suitable for permanent mechanical loads and under no circumstances can replace mechanical mounting or the use of a mounting adhesive. The mechanical load capacity of butyl rubber adhesives decreases with rising temperature. Adhesive tapes with butyl rubber adhesive are not solvent resistant. When winded at least twice, that is to say that at least to layers of Butyl cold shrink tape are mounted, the Butyl cold shrink tape is UV-stable.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Thickness | approx. 0.6 | mm | - |

| Width | 10 - 1000 | mm | - |

| Elongation At Break | 165.0 | % | ASTM D 882 |

| Tensile Strength | 23.0 | N/mm² | ASTM D 882 |

| Loop Tack | min. 233 | N | ASTM D 6195 |

| Peel Adhesion 180° | min. 211 | N/100mm | ASTM D 3330 |

| Density | min. 21.3 | g/cm³ | - |

| Solids Content | 100.0 | % | - |

| Temperature Resistance | 20 - 70 | °C | - |

| Processing Temperature | 5 - 30 | °C | - |

| Reaction To Fire | B2 normal inflammable | - | DIN 4102 |

Safety & Health

- Safety

Keep away from children.

Storage & Handling

- Storage

- 12 months after date of manufacture in the closed original container at max. 30 °C, protected against moisture.

- The storage location must be correctly ventilated. The backing paper is inclined to stick to the butyl adhesive, if the storage temperature exceeds 30 °C.