Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Typical Applications

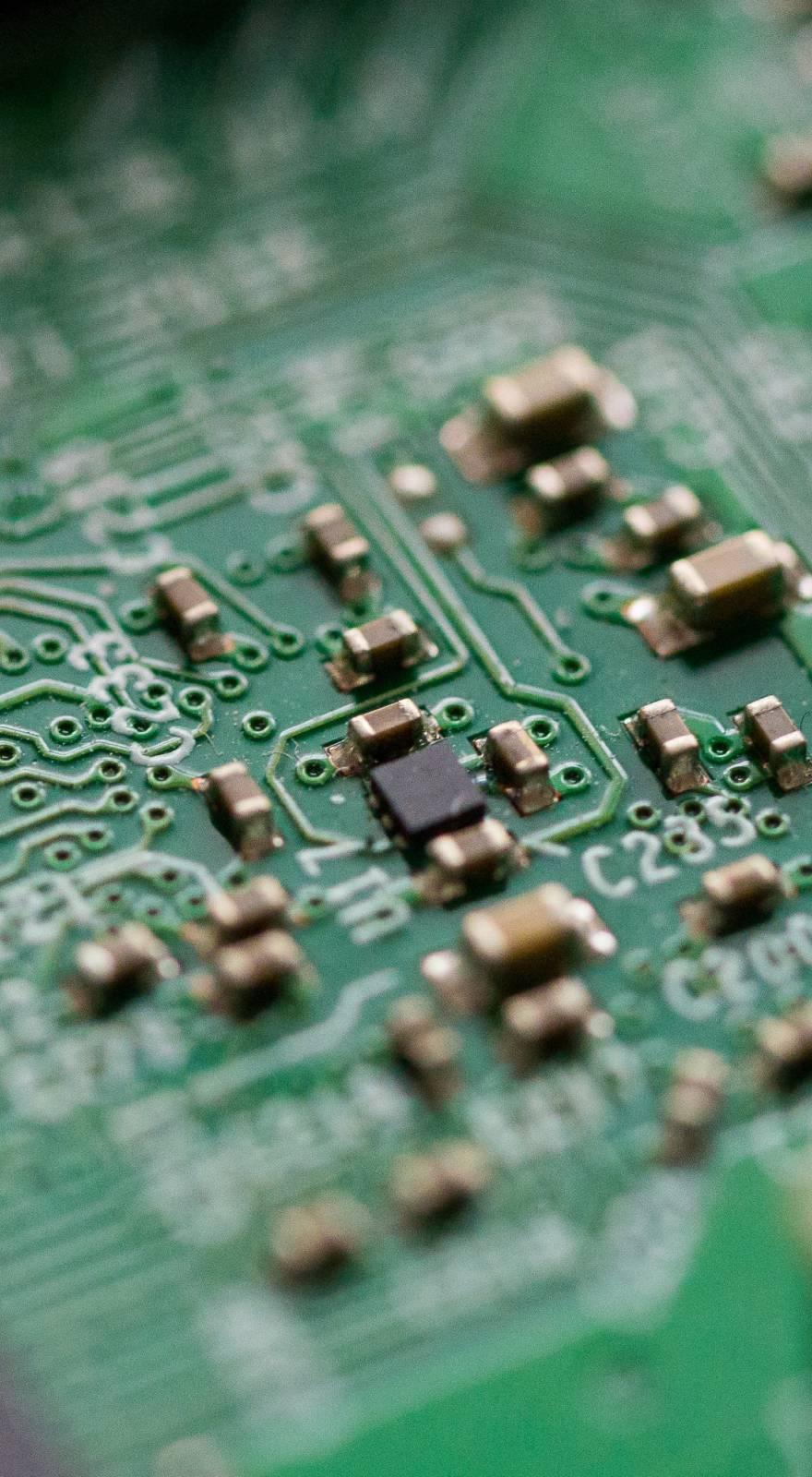

Densely packed power supplies, integrated circuits, thick film hybrid devices, D/A converters, delay lines, oscillators, minidac, operational amplifiers, binary devices, relays, transformers and semiconductors.

- Room Temperature Cure

- H-1 Hardener: Cures overnight at room temperature or 2 hours at 65°C. Do not heat cure if the mass exceeds 200 grams.

- H-18 Hardener: Cures overnight at room temperature or 2 hours at 65°C. Do not heat cure if the mass exceeds 200 grams.

- Mixing Instructions

Mix CC3-301AD thoroughly in it’s shipping container to insure a uniform consistency. Weigh out the desired amount of resin in a clean container. Add the hardener accurately by weight in the proper proportion as specified above. (ie. 5.4 grams of H-1 Hardener and 100 grams of CC3-301AD for a total mix of 105.4 grams) Mix thoroughly. Use in a well ventilated area and avoid contact with eyes and skin.

Properties

- Color

- Physical & Electrical Properties

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion | 28 x 10^(-6) | in/in/’C | — |

| Compressive Strength (25°C) | 19000.0 | psi | — |

| Dielectric Constant (25°C, 100 KC) | 5.6 | — | — |

| Dielectric Strength | 600.0 | volts/mil | — |

| Dissapation Factor (25°C, 100 KC) | 0.02 | — | — |

| Heat Distortion | 65.0 | °C | — |

| Izod Impact (of Notch) | 0.49 | ft lbs/in | — |

| Linear Shrinkage | 0.003 | in/in | — |

| Service Temperature (Continuous) | -65 - 150 | °C | — |

| Specific Gravity (Catalyzed, 25°C) | 1.76 | — | — |

| Specific Gravity (Uncatalyzed, 25°C) | 1.95 | — | — |

| Tensile Strength (25°C) | 7800.0 | psi | — |

| Thermal Conductivity | 1.25 | W/mK | — |

| Viscosity (Catalyzed, 22.5°C) | 1160.0 | cps | — |

| Viscosity (Uncatalyzed, 22.5°C) | 7400.0 | cps | — |

| Volume Resistivity (25°C) | 1015.0 | ohm-cm | — |

| Water Absorption (7 days, 25°C) | 0.3 | % | — |

Regulatory & Compliance

- Regulations

CC3-301AD meets MIL T-27, Grade 5, Class S; MIL STD. 202.111, FED TEST METHOD STD. 406-2021; and MIL I-16923, Types C and D.

Technical Details & Test Data

- Choice of Hardeners

- H-1 Hardener: Rigid, good dimensional stability, fast cure.

- H-18 Hardener: Resilient, excellent mechanical and thermal shock, low viscosity, good air release, fast cure.

HARDENER PARTS BY WEIGHT PER 100 PARTS OF RESIN POT LIFE 100 GRAM 25°C (77°F) CURE TIME 25°C (77°F) CURE TIME 65°C (149°F) CURE TIME 125°C (257°F)

H-1 Hardener 5.4 2 hrs. 24 hrs. 2 hrs. - - - H-18 Hardener 11 3 hrs. 24 hrs. 2 hrs. - - -