Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Structure

Aqueous dispersion of a HDPE wax

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Improves slip

- Improves antiblocking

- Improves scratch resistance

- Improves slip

- Suitable for gloss formulations

Applications & Uses

- Applications

- Coating Type

- Use Level

- 1 - 4%

- Fields of Application

ULTRALUBE® GA 1017 is especially recommended for waterbased overprint varnishes with direct food contact.

- Recommendation for Use

- We generally recommend a dosage of 1.0 - 4.0% ULTRALUBE® GA 1017 in aqueous coating systems related to the total formulation.

- The optimal dosage has to be determined in pre-trials.

- In aqueous coating systems the product is added during or at the end of the production process.

Properties

- Physical Form

- Stabilities

- ULTRALUBE® GA 1017 is sensitive to frost; after the impact of temperatures below the freezing point irreversible changes can occur.

- The containers must be protected from direct sun radiation and kept from temperatures higher than 30°C.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Performance Test

ULTRALUBE performance has been tested in 3 different OPV based on Indulor resins

Gloss [% GU] 20° 60° 85° OPV 1 - gloss 25% 76% 78% OPV 2 - semi gloss 12% 46% 50% OPV 3 - matt 4% 19% 19% Application conditions:

- 6 μm wet layer with K-Bar Hand Coater (RK Print Ltd.) on magenta pre-printed Cards. Drying for 24h at RT

Performance criteria:

Abrasion Resistance:

- Prüfbau Quartant Rub Tester

- 200 g weight, rubbing back and forth by a rotating motion

Anti-Blocking / Slip:

- Slip and Friction Tester, supplier TMI - Testing Machines Inc., based on ASTM D 1894 / ISO 8295

- Static and kinetic CoF - Coefficient-of-Friction (Speed: 30 cm/min / 200g weight)

Anti-Slip:

- Slip and Friction Tester, supplier TMI - Testing Machines Inc., based on ASTM D 1894 / ISO 8295

- Static CoF (Speed: 30 cm/min / 200g weight)

- Test Result

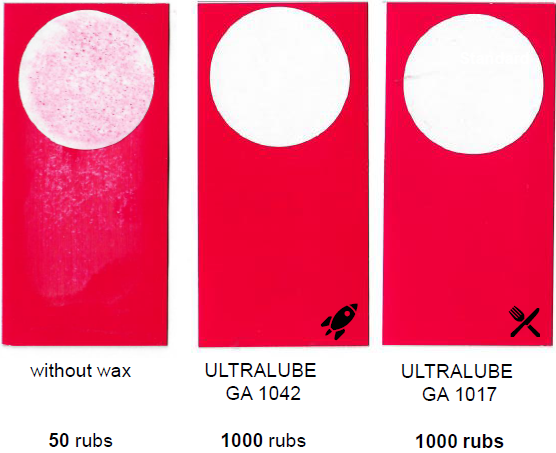

- Abrasion resistance - Evaluation of mechanical surface protection

- ULTRALUBE provides high durability of print while maintaining a high gloss levels

- 4.3% ULTRALUBE GA 1042 and 5.0% GA 1017 in OPV 1 - gloss

Product Comment Without ULTRALUBE

- ULTRALUBE GA 1042 best price-performance ratio suitable for indirect food contact

Storage & Handling

- Shelf Life

- 12 Months

- Storage Information

In closed original containers at room temperature (approx. 23°C) the product will be stable for at least 12 months.