Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- Features

- Forms stable emulsions in various water qualities.

- Multi-metal and general purpose applications.

- Free of chlorinated paraffins.

- Excellent corrosion prevention and residual corrosion properties reduce the need for in-process corrosion protection fluids.

- Reliable product performance keeps machinery clean.

- Wide application range reduces the need for several products.

- Increases the time between in-process operations and protects the machine tool parts from rust.

- Reduces disposal costs.

Applications & Uses

- Markets

- Application Area

- Compatible Substrates & Surfaces

- Applications

- Recommended for milling, turning, drilling, grinding, and other metalworking operations on ferrous and non-ferrous metals where efficiency of an emulsifiable oil is preferred.

- Preferred for grinding operations

Properties

- Appearance

- Amber

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity 60/60 | 0.94 | °F | ASTM D 1298 |

| Density | 7.83 | - | - |

| Flash Point, COC | 311.0 | °F | ASTM D92 |

| Viscosity (cSt at 40°C) | 111.0 | - | - |

| Pour Point | 32.0 | °F | ASTM D97 |

| pH (5% in Deionized) | 9.0 | - | - |

| Corrosion (modified Iron Chip Rust test) | Pass | - | - |

| Copper Corrosion (3 hrs at 212°F) | 1B | - | ASTM D130 |

| Emulsion Stability, ( 24 hrs at 77°F) Deionized Water | Pass | - | - |

| Emulsion Stability, ( 24 hrs at 77°F) Hard Water | Pass | - | - |

| Solution Stability, 24 hrs at 30°F | Pass | - | - |

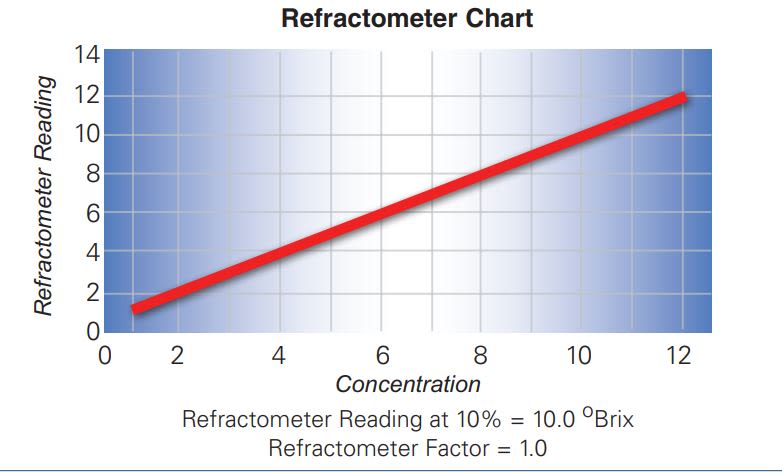

Technical Details & Test Data

- Refractometer Chart

- Material Compatibility

P-Steels Highy Recommended M-Stainless Steel Highy Recommended K-Cast iron Recommended N-Non-ferrous Highy Recommended - METAL MACHINABILITY GROUPS

Machining Operation Non-Ferrous,

Soft Metals^{(2)}Nickel Alloys,

Nitralloy

Steels, Cast

Irons and Alloy

Steels (up to

200 Brinell)Stainless Steels,

“Monel” Met-als, Cast Irons

and Alloy Steels

(200 to 300

Brinell)Titanium Alloys,

High Tensile Nickel

Alloys, Austentic

Stainless Steels,

Tool Steel and High

Tensile Alloy Steels

(300 to 400 Brinell)Turning, Boring, Milling,

Forming, Drilling, Sawing5-7% 5-7% 7-9% 7-9% Tapping, Thread Rolling,

Reaming, Screw Cutting,

Broaching5-7% 5-7% 8-10% 8-10% Gear Shaping, Form and

Thread Milling, Shaving,

Hobbing, and Trepanning5-7% 5-7% 8-10% 8-10% Internal and External

Grinding, Form and

Thread Grinding5-7% 5-7% 5-7% 5-7% Stamping 10% 10% 20% 20%

Packaging & Availability

- Packaging Type