Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Applications

ECA 100NC is a low viscosity, light colored, non-crystallizing which blend is based blend of methylhexahydrophthalic anhydride, hexahydrophthalic anhydride, and methyltetrahydrophthalic anhydride.. This liquid anhydride epoxy curing agent is designed for converting epoxy resins to highly cross-linked polymers with excellent physical and electrical properties.

- Non-crystallizing

- Good substitute for HHPA in most electrical and electronic applications.

- Good outdoor durability (UV resistance).

- Good alkaline resistance in pipe applications.

- Low color of cured polymer

ECA 100NC imparts ease of handling due to low viscosity, low toxicity and low volatility. ECA 100NC is particularly important to compounders who wish to insure that their customers receive filled compound in liquid condition. If the product crystallized during low temperature transit and/or storage, it will return to a liquid at 25°C or less.

When properly formulated with promoters and blended with bisphenol-A, cycloaliphatic, glycidyl ethers or novolac epoxide resins, heat cured systems yield excellent properties in filament wound, pultrusion and laminated forms, as well as, electrical potting, casting, insulating and encapsulating applications.

Properties

- Physical Form

- Appearance

- Clear to Light Yellow Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 1.166-/+0.015 | g/cc | D-102 (ASTM D 4052) |

| Viscosity | 40-80 | cP | D-150F |

| Free Acid | max. 2 | % | D-160B-3 |

| Molecular Weight (Average) | 164 - 166 | — | — |

Technical Details & Test Data

- Formulation Example

ECA 100NC was formulated with a variety of epoxy resins. Viscosity was measured at 25°C, and gel time was measured at 100°C. Samples were cured for 1 hour at 120°C, followed by a post-cure of 1 hour at 220°C, and glass transition temperatures were measured using a differential scanning calorimeter. The following table summarizes these results:

Epoxy type ECA 100NC, phr Viscosity at 25°C, cP Gel Time min Tg, (°C) Standard BPA Liquid Epoxy 83 960 35.8 157 Low Viscosity BPA Liquid 86 720 35.5 154.4 Cycloaliphatic Epoxy 114 170 50.9 225.7 Epoxy Phenol Novolac 91 900 39.6 154 Epoxy BPA Novolac 82 3900 31.6 167.9 BPF Liquid Epoxy 92 980 39.4 144.8 - Cure Catalysts

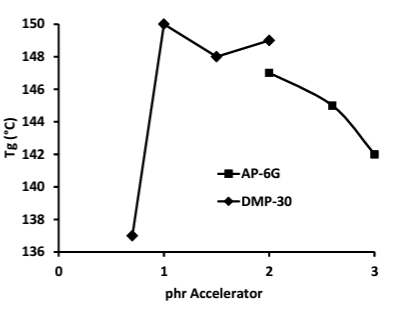

Dixie Chemical Company makes a liquid blend of benzyltriethylammo-nium chloride and ethylene glycol. Named AP-6G, this liquid can be easily and conveniently dispersed in liquid epoxy-ECA 100NC blends. AP-6G imparts good glass transition temperature (Tg) and extended pot life to anhydride/epoxy formulations, and allows the production of light colored polymers.

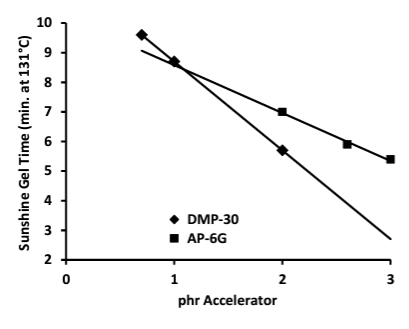

Liquid BPA epoxy resin (100 parts) was formulated with ECA 100NC (84 parts). Samples were catalyzed at various levels with either AP-6G or 2,4,6-tris(dimethylaminomethyl) phenol (DMP-30 from Dow Chemical or Ancamine K-54 from Air Products). Sunshine gel times (ASTM D3056-85) were measured. Samples were cured for 30 minutes at 100°C, the temperature was raised to 160°C over ten minutes, and the cure was continued for a total of 70 minutes.

Glass transition temperatures (Tg) were measured. The results are summarized in the following plots:

Safety & Health

- Health Hazards

These anhydrides are primary skin and eye irritants. Avoid contact with skin, eyes, and clothing. Use only with adequate ventilation. In case of contact, follow the procedures outlined in the SDS. Generally, these procedures include immediately flushing the affected skin or eyes with copious amounts of water for at least 15 minutes.

In the case of eye contact, get medical attention. Wash contaminated clothing before reuse. Follow the recommendations in the SDS for personal protective equipment when handling these materials. At a minimum, these procedures typically include protective chemical goggles, impenetrable gloves, and measures to avoid breathing chemical vapors.

Storage & Handling

- Storage

ECA 100NC will react with water to form diacids. This is normally undesirable, so ECA 100NC should be stored in such a way that it is carefully protected from moisture contamination. For more details on the design of bulk storage for ECA 100NC, consult the Dixie Chemical Company brochure “Epoxy Curing Agent Storage Requirements.”