Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Cosmetic Ingredients Functions

- CAS No.

- 78330-21-9

- Technologies

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Multifunctional product: thickening and emulsifying

- Ready to use for controlling the rheology of aqueous formulations

- Silicone carrier provides instant perception of improved esthetics

- Ease of formulation/cold processing

- Gives smooth, non-greasy and non-sticky formulations

- Freeze/thaw stable

Applications & Uses

- Markets

- Hair Care Applications

- How to Use

ACULYN 2051 Rheology Modifier should be mixed before use. Oil-in-water emulsions can be prepared by adding ACULYN 2051 Rheology Modifier to the oil phase and then mixing with the water phase. The oil phase containing ACULYN 2051 Rheology Modifier can be added to the water phase, or the water phase can be added to the oil phase. If the water phase is added to the oil phase, the emulsion inverts as the water phase is added, and this can reduce the particle size of the final emulsion. Alternatively, ACULYN 2051 Rheology Modifier can be added after the oil phase and water phase have been combined. Regardless of which technique is used, the mixer speed should be increased as the formulation thickens to maintain good mixing.

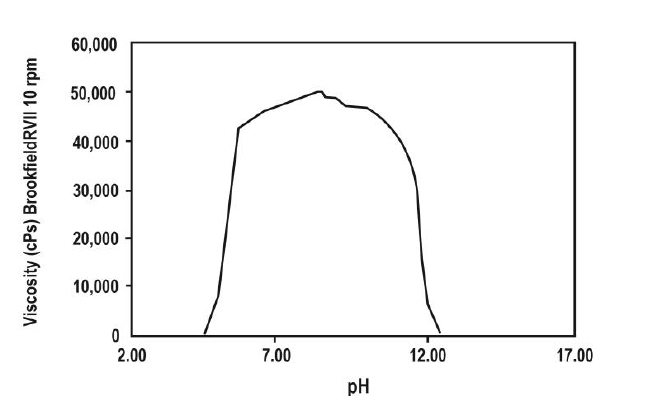

The effective pH range of 5.5 to 11 (Figure 1) allows the use of ACULYN 2051 Rheology Modifier in a variety of personal care formulations. The recommended addition level is 2 to 6%.

Figure 1: Viscosity of an Aqueous Gel Containing 5% Thickening Agent Versus pH.

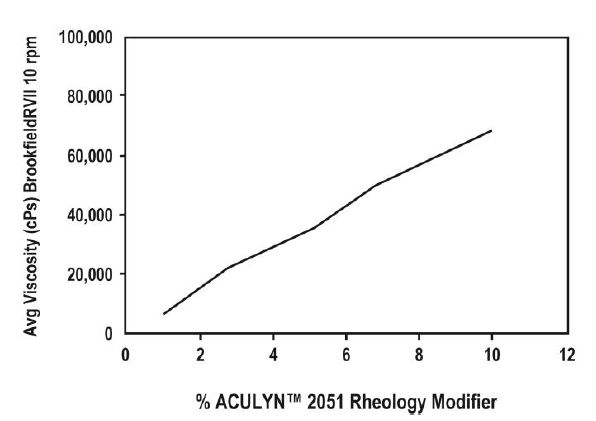

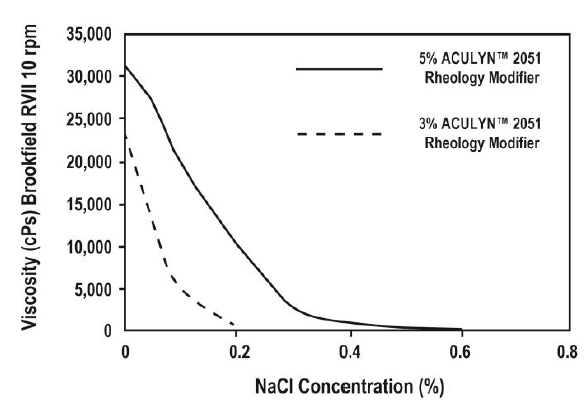

ACULYN 2051 Rheology Modifier can emulsify and stabilize silicone and organic oil phases. The level of oil that can be emulsified depends on the level of the thickening agent (Figure 2), which will determine final viscosity and stability. For example, the thickening agent can typically emulsify from 20% to 50% oil, depending on its type. It can be used with high solvent content (30% ethanol, isopropyl alcohol or acetone, 50% glycerin or propylene glycol). Thickening efficiency is reduced in the presence of electrolytes (Figure 3).

Figure 2: Average Viscosity of an Aqueous Gel Versus Thickening Agent Content.

Figure 2: Average Viscosity of an Aqueous Gel Versus Thickening Agent Content. Figure 3: Viscosity of an Aqueous Gel Containing 5% Thickening Agent Versus Sodium Chloride Concentration.

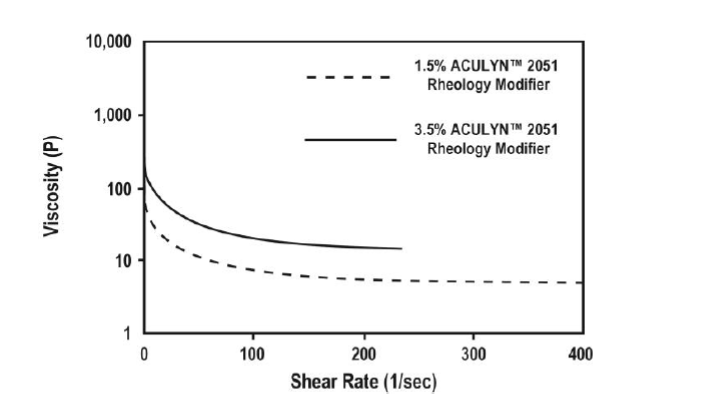

Figure 3: Viscosity of an Aqueous Gel Containing 5% Thickening Agent Versus Sodium Chloride Concentration.The material has a noticeable shear-thinning effect. Its higher viscosity at low shear translates to maximum emulsion stability, while viscosity drop with shear allows the product to be easily dispensed and spread onto the skin or hair (Figure 4).

Figure 4: Rheological Profile Based on Two Levels of Thickening Agent.

Properties

- Physical Form

- Appearance

- White to light yellow viscous, opaque liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point | min. 100 | °C | — |

| Freeze/Thaw Stability (at -30°C) | Three cycles | — | — |

| pH (1% in water) | 5.5 - 6.5 | — | CTM0007 |

| Viscosity (LVT, Spindle 3 at 30 rpm) | 1500 - 4000 | cP | CTM0050 |

| Viscosity (RV, Spindle 6 at 20 RPM, 1% active in water) | 15000 - 30000 | cP | CTM0050 |

Regulatory & Compliance

- Chemical Inventories

Safety & Health

- Limitations

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

Packaging & Availability

- Packaging Information

- This product is available in 25 kg pails and 130 kg drums.

- Samples are available in 500 g bottles.

Storage & Handling

- Shelf Life

- 18 Months

- Usable Life & Storage

- Stored at or below 30°C (86°F) in the original unopened containers, this product has a usable life of 18 months from the date of production. Avoid freezing.

- It demonstrates freeze/thaw stability over three cycles at -30°C (-22°F).