Knowde Enhanced TDS

Identification & Functionality

- Carrier

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Composition

Approximately 15.5 wt. percent Dimethicone Crosspolymer, Dimethicone/Vinyl Dimethicone Crosspolymer and a high molecular weight Dimethiconol in Cyclopentasiloxane (D5).

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Cross-linked silicone elastomer gel

- Easy to formulate

- Acts as a thickening agent for water-in-oil and water-in-silicone formulations and other silicone fluids

- Provides dry smoothness and a light, silky, non-greasy skin feel

- Enhances the esthetics of volatile silicone fluids

- May improve fragrance retention

- Reduces tackiness of formulations

- Slight sebum absorption

- Quick absorption

- Cold processing

- Increased suspension of antiperspirant salts

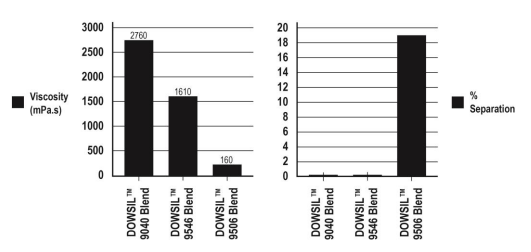

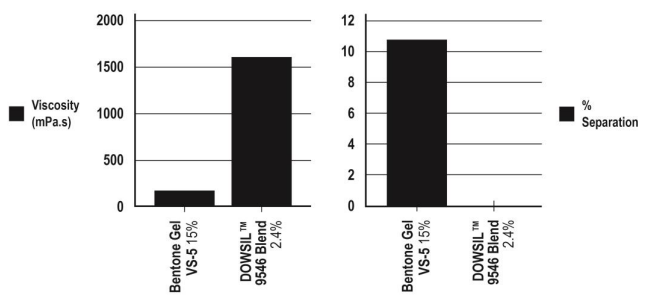

DOWSIL™ 9546 Silicone Elastomer Blend Develops an Acceptable Viscosity for a Roll on with a Low Solvent Seperation.

Viscosity and % of solvent separation in a roll-on formulation using DOWSIL™ 9040 Silicone Elastomer Blend, DOWSIL™ 9546 Silicone Elastomer Blend and DOWSIL™ 9506 Powder at 2.4% solids.

- Reduced volatile silicone fluids syneresis in antiperspirant and deodorants.

Applications & Uses

- Markets

- Application Format

- AP/Deo Applications

- Hair Care Applications

- Sun Care Applications

- Recommended Usage

- DOWSIL™ 9546 Silicone Elastomer Blend can be used similarly to DOWSIL™ 9040 Silicone Elastomer Blend and DOWSIL™ 9041 Silicone Elastomer Blend. However, due to the higher viscosity of DOWSIL™ 9546 Silicone Elastomer Blend, it is recommended to premix it with the other ingredients that comprise the oil phase in order to make sure that the oil phase is homogeneous.

- This blend should be prepared by mixing the ingredients slowly with a spatula or a U blade. Do not use high shear. In some cases there are systems that include emulsifiers or waxes that require high temperatures to melt. For these systems, it is recommended to make the emulsion first and then cool down the mixture to 50°C and then add the DOWSIL™ 9546 Silicone Elastomer Blend premixed with part of the oils that comprise the oil-phase.

- This helps to avoid the evaporation of the volatile components that comprise DOWSIL™ 9546 Silicone Elastomer Blend. If your system is transparent, it is recommended to add from one to three percent of an ester, or an alkoxy alcohol (i.e. C12-15 Alkyl Benzoate, PPG-3 Myristyl Ether or Isononyl Isonanoate). The addition of one of these ingredients can also affect the viscosity of your final product.

- Clear systems can be prepared by making a water-in-silicone emulsion using DOWSIL™ 9546 Silicone Elastomer Blend in combination with a silicone formulation aid such as DOWSIL™ 5225C Formulation Aid or in combination with an emulsifying elastomer such as DOWSIL™ 9011 Silicone Elastomer Blend.

- These systems can be prepared using levels up to 60 weight percent oil-phase. However, it has been shown that formulations that utilize greater than 30% oil-phase are less esthetically pleasing than those formulations that contain 30% or less.

Formulation Tips

DOWSIL™ 9546 Silicone Elastomer Blend may be formulated into oil-in-water emulsions, water-in- silicone emulsions, water-in-oil emulsions and anhydrous products.

- It can be added to the oil phase or silicone phase in an emulsion formulation.

- It can be post-added to emulsions provided the emulsion is viscous enough for the DOWSIL™ 9546 Silicone Elastomer Blend to be dispersed.

- For ease of use, its viscosity may be reduced by blending with dimethicone or cyclomethicone.

- It may be formulated with organic oils and silicone-based materials with the use of mixers and may be subjected to high shear devices such as homogenizers and sonolators.

- It is dispersible in a variety of liquid oils

- Because the Elastomer is stable, DOWSIL™ 9546 Silicone Elastomer Blend may be subjected to heat for a short duration. When heat is used, the material should be processed in an enclosed vessel to prevent the Cyclopentasiloxane from volatilizing; the vessel should be inerted at temperatures over 60°C (140°F).

Processing

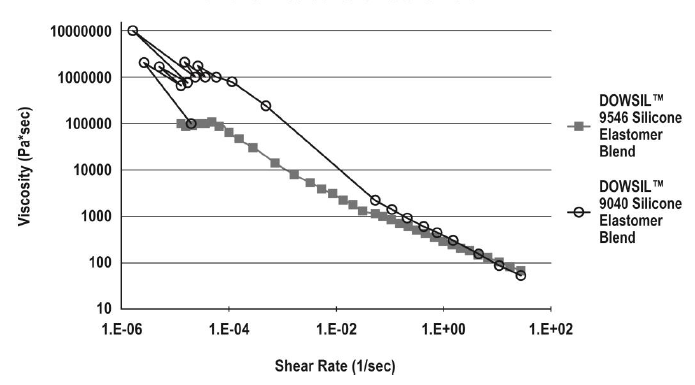

DOWSIL™ 9546 Silicone Elastomer Blend is a viscous product but has the unique characteristic of being a shear-thinning material. The following information will aid in the selection of the proper equipment to use when processing DOWSIL™ 9546 Silicone Elastomer Blend out of a drum.

Rheological flow comparison of DOWSIL™ 9546 Silicone Elastomer Blend and DOWSIL™ 9040 Silicone Elastomer Blend.

Pump Selection

One possible pump that can be used is a GRACO Bulldog 10:1 Pump with follower plate. For more information, contact GRACO at +1 800 367 4023.

Note: GRACO offers various Bulldog models, and other pump manufacturers may offer similar equipment equally capable of processing this material efficiently. Users should work directly with the pump manufacturer to determine the best design for their needs.Customer-specific Pump Design Considerations

- Pressure and flow requirements

- Air supply pressure: will depend on plant s air supply capabilities.

- Discharge pressure: will depend on total pressure required to move the silicone elastomer blend from point A to point B. Pressure drops due to elevation, frictional losses within the piping, fittings, valves, filters, etc., will need to be considered.

- Flow requirements: will depend on how quickly the user wishes to transfer the silicone elastomer blend from a 208 liter (55 gal) drum into a vessel.

- Construction material for wetted parts: Stainless steel is recommended but carbon steel may also be used.

- Construction materials for seals and gaskets: Viton or Teflon materials are recommended.

Clean-up

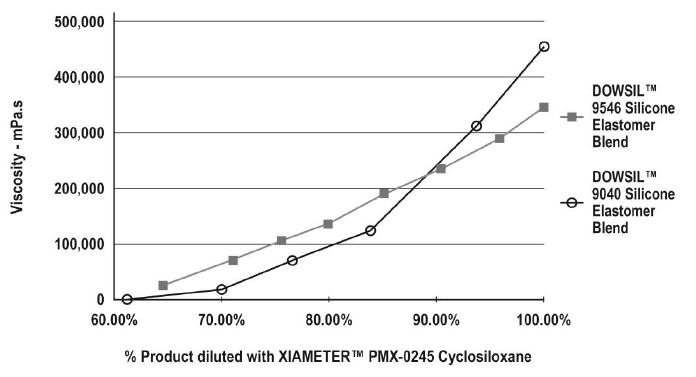

XIAMETER™ PMX-0245 Cyclopentasiloxane, which dilutes the viscosity of DOWSIL™ 9546 Silicone Elastomer Blend to water-thin, is recommended for soaking or cleaning equipment. Other non-polar solvents may work as well.

Properties

- Physical Form

- Appearance

- Slightly hazy colorless to light amber no significant particulate

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (Spindle 94, at 2.5 rpm, Helipath RV TD) | 250000 - 450000 | mm²/s | Corporate Test Method 0050 |

| Non Volatile Content (2g, at 150°C, 3h, Al Cup, forced draft) | 15.00 - 16.00 | % | Corporate Test Method 0208 |

| Cyclotetrasiloxane (D4) Content | max. 1 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

Dilution curves comparing DOWSIL™ 9546 Silicone Elastomer Blend and DOWSIL™ 9040 Silicone Elastomer Blend.

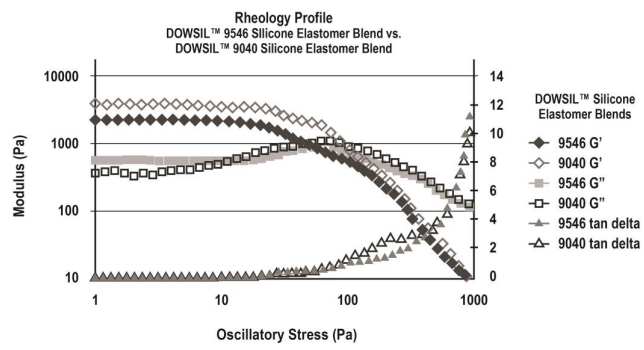

Rheology profile comparison of DOWSIL™ 9546 Silicone Elastomer Blend and DOWSIL™ 9040 Silicone Elastomer Blend.

Effect on the viscosity with Bentone gel VS 5 and DOWSIL™ 9546 Silicone Elastomer Blend AP/Deo formulation with XIAMETER™ PMX-0245 Cyclopentasiloxane as the solvent.

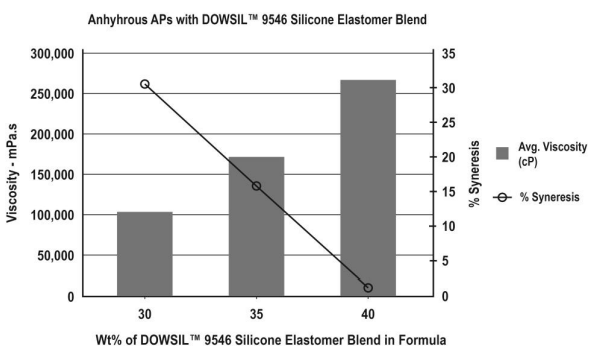

- DOWSIL™ 9546 Silicone Elastomer Blend Reduces Syneresis

In soft solid applications, DOWSIL™ 9546 Silicone Elastomer Blend significantly reduces syneresis.

Elastomer Type % Elastomer in Formulation % XIAMETER™ PMX-0245 Cyclosiloxane % C12-15 Alkyl Benzoate % REACH AZP 908 SUF % Syneresis Average Viscosity (cP)

DOWSIL™ 9546 Silicone Elastomer Blend 30 42 3 25 30.4 104320 DOWSIL™ 9546 Silicone Elastomer Blend 35 37 3 25 16.3 168480 DOWSIL™ 9546 Silicone Elastomer Blend 40 32 3 25 1.6 265600 - Sun Protection Lotion - Formulation CPF 1745

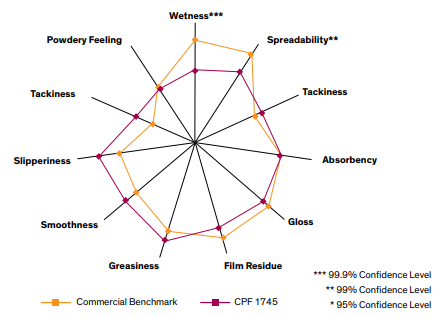

This sun protection lotion provides high protection from UVA/ UVB (SPF 35/PA++ in vitro). It has a similar sensory profile as a commercial benchmark, except for wetness and spreadability.

Featured products:

- 5% DOWSIL(TM) 9546 Silicone Elastomer Blend

- 3% DOWSIL(TM) 5200 Formulation Aid

- 3% DOWSIL(TM) FZ-3196 Fluid

- 3% DOWSIL(TM) MQ-1640 Flake Resin

Figure: Sun Protection Lotion CPF 1745 has a more slippery, smooth feel and less film residue feel than the oil-in-water commercial benchmark

Packaging & Availability

- Packaging Information

This product is available in 15 kg pails and 180 kg drums. Samples are available in 0.4 kg cans.

Storage & Handling

- Shelf Life

- 24 Months

- Usable Life and Storage

When stored at or below 60°C (140°F) in the original unopened containers, this product has a usable life of 24 months from the date of production.