Knowde Enhanced TDS

Identification & Functionality

- Carrier

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Highlights

- Provides a light, silky after feel

- Optical blurring benefits

- Minimize appearance of pores

- Mask fine lines and wrinkles

- Slight sebum absorption

Applications & Uses

- Markets

- Application Format

- Sun Care Applications

- Directions of Use

DOWSIL 9576 Smooth Away Elastomer may be formulated into oil-in-water emulsions, water-in- silicone emulsions, water-in-oil emulsions and anhydrous products to create unique beauty care products.

- Compatibility of DOWSIL 9576 Smooth Away Elastomer

Compatibility of DOWSIL 9576 Smooth Away Elastomer with common cosmetic ingredients:

Cosmetic Ingredients (INCI)

DOWSILTM 9576 Smooth Away (Elastomer to Cosmetic Ingredient) 21:20 80:20:00 XIAMETERTM PMX-200 Silicone Fluid 1.5 cSt M M XIAMETERTM PMX-200 Silicone Fluid 5 cSt M S DOWSILTM 556 Cosmetic Fluid M M DOWSILTM FZ-3196 Fluid M PM Isododecane M S C12-15 Alkyl Benzoate M S Caprylic/Capric Triglyceride M S M: Miscible, S: Separates, PM: Partially miscible

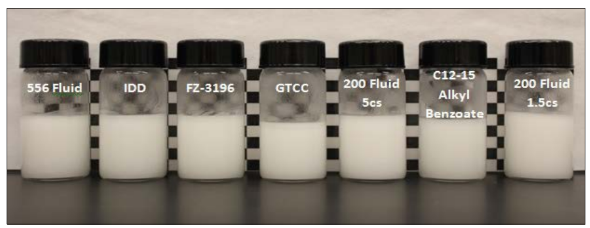

Photograph of 80% DOWSIL 9576 Smooth Away Elastomer: 20% ingredient

Full product names are stated in the above table.

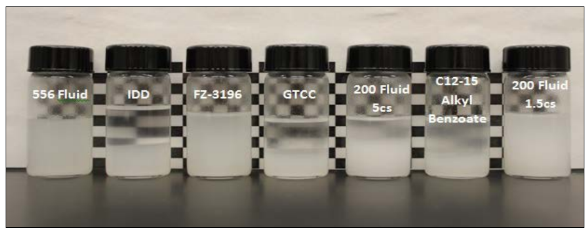

Photograph of 20% DOWSIL 9576 Smooth Away Elastomer: 80% ingredient

Full product names are stated in the above table.

- Tips for Formulations

- May be pre-mixed in an oil-phase or silicone phase in an emulsion formulation. When mixing with the other ingredients in the oil phase, insure that the oil phase is homogeneous.

- May be posted to emulsions provided the emulsion is viscous enough to allow the DOWSIL 9576 Smooth Away Elastomer to be adequately dispersed.

- Viscosity maybe reduced by adding silicone fluids such as volatile dimethicone fluids or cyclomethicones.

- May be formulated with organic oils and silicone-based materials with the use of mixers and may be subjected to high shear such as homogenizers or sonicators.

- May be subjected to heating for a short time. When heat is necessary, it is recommended that DOWSIL 9576 Smooth Away Elastomer be processed in a closed vessel/container to prevent the loss of volatile silicone fluids. The vessel should be inerted at temperatures over 60°C. Heating at temperatures above 65°C will cause the beeswax to melt so mixing is recommended to maintain product homogeneity at these higher temperatures.

- Can be dispersed in a variety of organic oils. Please refer to the following compatibility tables and pictures of DOWSIL 9576 Smooth Away Elastomer in various cosmetic ingredients.

- Processing Recommendations

DOWSIL 9576 Smooth Away Elastomer is a viscous product that exhibits shear thinning behavior. The following information will aid in the selection of the proper equipment to use when processing DOWSIL 9576 Smooth Away Elastomer out of a drum.

Pump Recommendation:

GRACO BULLDOG® 10:1 Pump with follower plate.

Note: GRACO offers various models, and other pump manufacturers may offer similar equipment equally capable of processing the material efficiently. Users should work directly with the pump manufacturer to determine the best design for their needs.

Customer - specific pump design considerations:

- Pressure and flow requirements

- Air supply pressure: Will depend on plant’s air supply capabilities.

- Discharge pressure: Will depend on total pressure required to move the silicone organic elastomer blend from point A to point B. Pressure drops due to elevation, frictional losses within the piping, fittings, valves, filters, etc., will need to be considered.

- Flow requirements: Will depend on how quickly the user wishes to transfer the silicone organic elastomer blend from a 208 liter (55 gallon) drum into a vessel.

- Material viscosity in cP (mPa·s) at the application temperature: DOWSIL 9576 Smooth Away Elastomer is shear thinning. It is the responsibility of the user to determine the effective viscosity based on the user’s application. Once the material is pushed through the pump by the follower plate and processed in the pump, the product will shear thin and process as a lower viscosity fluid.

- Construction material for wetted parts: Stainless steel is recommended but carbon steel may also be used.

- Construction material for seals and gaskets: VITON® or TEFLON® materials are recommended.

- Pressure and flow requirements

- Equipment Clean Up

Non-polar organic or silicone solvents are recommended for soaking or cleaning equipment.

Properties

- Physical Form

- Appearance

- White to off-white gel

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (Helipath RV TD, Spindle 94, 2.5 RPM) | 150,000 - 600,000 | cP | CTM0050 |

| Non Volatile Content (2g/150°C/3h/Al Cup, forced draft) | 15 - 17 | % | CTM0208 |

| Flash Point (Closed cup) | 74.0 | °C | — |

| Specific Gravity | 0.9 | — | — |

| Cyclotetrasiloxane (D4) Content | max. 0.1 | % | — |

| Cyclopentasiloxane (D5) Content | max. 0.1 | % | — |

Packaging & Availability

- Packaging Information

This product is available in 15 kg pails and 170 kg drums. Samples are available in 500 ml bottles.

Storage & Handling

- Shelf Life

- 720 Days

- Storage and Shelf Life Conditions

When stored at or below 60°C (104°F) in the original unopened containers, this product has a usable life of 24 months from the date of production.