Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Product Families

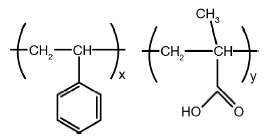

- Chemical Structure

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Imparts uniform opacity and lotionized appearance to formulations

- Effectively hides amber cast or haziness in formulations

- Imparts high whiteness or a pastel color effect to formulation when used with dyes

- Excellent compatibility allows for use in a wide variety of applications

- Effective at low use levels

- Easy-to-use liquid

Applications & Uses

- Markets

- Applications

- Bath & Shower Applications

- Hair Care Applications

- Personal Hygiene Applications

- Skin Care Applications

- Use Level

- 0.5 - 1.0 %

- Recommended Applications

OPULYN™ 301 Opacifier is a highly versatile opacifier for anionic surfactant-based systems. Best suited for formulations with slightly acid to moderate pH range, containing up

to moderate levels of inorganic electrolytes, such as:- Mild shower gels and shampoos

- Fatty-acid based liquid hand soaps

- Formulation Guidelines

Formulation components, ionicity and pH should be chosen for optimal formulation stability.

-

Order of Addition

- For maximum results, it is recommended that OPULYN™ opacifiers are diluted with product water (held out of the formulation) added slowly as the final component to the formulation (after pH adjustments, addition of dye, salt, perfume, etc.). Good agitation should be maintained throughout the addition process. If pre-dilution is not possible or desired, OPULYN™ opacifiers can also be added directly to formulation slowly and with good agitation. If desired, OPULYN™ opacifiers can also be added directly after the formulation initial water charge.

-

Neutralization

- Due to low dosage rates, the low pH of OPULYN™ 301 Opacifier should not affect the pH of the final formulation. Note: if tap water is used to pre-dilute, the pH will automatically increase to pH 4–5 and neutralization may not be required.

-

Compatibility

- There are several formulation parameters that can affect the stability of an opacified formulation, such as level of electrolytes and cationic ingredients, the pH and choice of surfactants. All of the OPULYN™ opacifiers behave differently in these systems. OPULYN™ 301 Opacifier has the broadest compatibility across a variety of applications. Both OPULYN™ 303B Opacifier and OPULYN™ 305 Opacifier offer a very good compatibility in the presence of high levels of inorganic electrolytes. In addition, OPULYN™ 303B Opacifier also has very good compatibility with cationic-based systems with low levels of anionic surfactants. OPULYN™ 302B Opacifier is the preferred choice for formulations with soft preservatives due to its compatibility in the lower pH range.

-

Evaluating Formulation Stability

- Four week stability tests under high, low and room temperature conditions as well as 3 cycles of freeze/thaw stability are recommended as a best practice for any formulation containing opacifiers.

-

Overcoming Depletion Flocculation

- Flocculation and sedimentation are the two most common symptoms of formulation instability. Certain conditions, such as high betaine levels, high electrolyte levels or the presence of cationic ingredients, can pose additional stability challenges in a formulation. For these specific conditions, ACULYN™ 28 Rheology Modifier or ACULYN™ 88 Rheology Modifier are the preferred choice as a primary or secondary thickening agent. Their high efficiency and excellent suspension performance will both build viscosity and help to prevent flocculation or sedimentation.

-

Cleaning

- After use, process equipment should be cleaned with high pressure washing or an appropriate cleaning solution.

-

Properties

- Physical Form

- Appearance

- Opaque white to off-white liquid, free of visible impurities

- Typical Properties

- Microbiological Values

| Value | Units | Test Method / Conditions | |

| Gel Part (on 150 Micron) | 0 - 50 | ppm | CTG 3240 |

| Gel Part (on 45 Micron) | 0 - 100 | ppm | CTG 3240 |

| pH (at Shipment) | 2.05 - 2.50 | — | DOWM 102574 |

| Solids Content (Forced Draft Oven, at 150°C, 0.6 g, 20 min) | 39.00 - 41.00 | % | DOWM 102570 |

| Viscosity (Brookfield, LV, Spindle #1, 60 rpm, 25°C) | 0 - 50 | cP | DOWM 102715 |

| Particle Size | 0.18 | microns | — |

| Preservative | None, self-preserved | — | — |

| Active Content | 40 | % | — |

| Value | Units | Test Method / Conditions | |

| Candida albicans | Absent | per g | DOWB 508040 |

| Gram Negative Bacteria | Absent | per g | DOWB 508040 |

| Staphylococcus aureus | Absent | per g | DOWB 508040 |

| Aerobic Plate Count | max. 100 | CFU/g | DOWB 508040 |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Safety Information

OPULYN™ 301 Opacifier has a safe toxicological profile for a broad range of personal care products.

Storage & Handling

- Usable Life and Storage

OPULYN™ 301 is supplied as a 40% solids emulsion with a maximum viscosity of < 50 cps at room temperature (25°C). The recommended storage temperature for this material is 4°C to 40°C. Keep from freezing. If exposed to temperatures below 4°C or above 40°C for extended periods, material may become unusable.