Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

Dynalene 600 is not corrosive towards metals and is compatible with a variety of polymers commonly used to make gaskets, valves, and other components of heat transfer fluid systems. The fluid demonstrates low toxicity and low flammability. In addition, the low evaporation rate makes it a good choice to minimize fluid loss in open bath systems.

Thermal Stability

The maximum operating temperature of Dynalene 600 is 288°C (550°F) in an open system and 350°C (662°F) in a closed system. Dynalene 600 shows excellent resistance to viscosity breakdown at high temperatures. The fluid demonstrates no change in its physical properties after continuous operation up to 350°C in closed systems.

- Benefits

- Low oral toxicity

- High thermal stability

- High flash point

- Odorless

- Low evaporation rate

- Cost-effective

- Available worldwide

- Total fluid care option

- Proven performance

- Resistant to oxidation

Applications & Uses

- Markets

- Application Area

- Compatible Substrates & Surfaces

- Applications

- High temperature applications

- Open baths

- Quenching tanks

- Hydraulic & mechanical equipment

- Pharmaceutical

- Process heating & cooling

Properties

- Color

- Appearance

- Polydimethylsiloxane, Dark brown, orange

- Odor

- None

- Typical Properties

- Properties

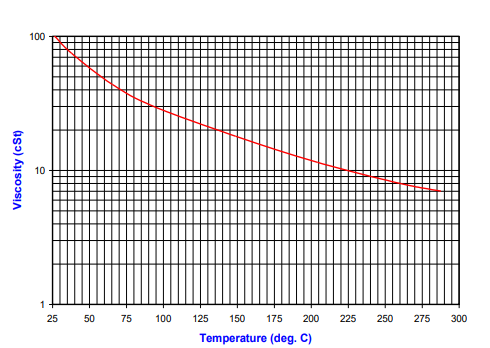

Temperature Viscosity Thermal Conductivity Specific Heat Density °C mPa·s W/m·K kJ/kg·K kg/m^{3} 70 48.6 0.147 1.368 911 71 47.7 0.147 1.368 909 82 40.4 0.145 1.389 898 93 34.5 0.143 1.41 887 104 29.6 0.141 1.431 875 116 25.7 0.139 1.452 864 127 22.4 0.137 1.473 853 138 19.7 0.135 1.494 843 149 17.5 0.133 1.515 832 160 15.6 0.131 1.535 821 171 13.9 0.129 1.556 810 182 12.5 0.127 1.577 798 193 11.3 0.125 1.598 787 204 10.3 0.123 1.619 776 216 9.4 0.121 1.64 765 227 8.6 0.119 1.661 754 238 7.9 0.117 1.682 742 249 7.3 0.115 1.703 731 260 6.7 0.113 1.724 720 271 6.2 0.111 1.745 709 282 5.8 0.109 1.766 699 288 5.6 0.108 1.778 693

| Value | Units | Test Method / Conditions | |

| Recommended Temperature Ranges (Closed systems) | 70 - 350 | °C | — |

| Recommended Temperature Ranges (Open systems) | 70 - 288 | °C | — |

| Pour Point | max. -65 | °C | — |

| Initial Boiling Point | min. 315 | °C | — |

| Flash Point | 315.0 | °C | — |

| Percent Weight Loss (249°C,After 4 hours) | 2.0 | — | — |

| Percent Weight Loss (249°C,After 1 day) | 4.5 | — | — |

| Percent Weight Loss (249°C,After 2 day) | 7.0 | — | — |

| Percent Weight Loss (288°C,After 4 hours) | 3.0 | — | — |

| Percent Weight Loss (288°C,After 1 day) | 9.4 | — | — |

| Percent Weight Loss (288°C,After 2 day) | 11.5 | — | — |

| Gel Time (199°C) | min. 19,000 | hours | — |

| Gel Time (288°C) | min. 5,000 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Quantity & Availabiliy

Dynalene 600 is offered in 1, 5, and 55-gallon containers.