Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

Dynalene HT is noncorrosive and very stable where temperatures exceed the thermal stress limitations of most competitive fluids, such as mineral oils that begin to degrade at lower temperatures.

Materials Compatibility

All materials must have the required resistance to temperature and pressure. Cadmium and zinc are not considered suitable as they catalyze the thermal breakdown of the fluid. Copper and brass may promote oxidation and should only be used in oxygen-free systems. PTFE and other fluoropolymers are suitable for Dynalene HT up to the polymer manufacturer's recommended temperature. Thermoplastics such as PVC, polyethylene, and most types of rubber are not recommended.

- Benefits

• High boiling, flash, and fire points

• Low vapor pressure

• Low toxicity

• Excellent thermal stability and thermo-physical properties

• Low odor

• High autoignition temperature

• Available worldwide

• Cost-effective

• Total fluid care option

• Proven performance

Applications & Uses

- Applications

- Applications

- High-temperature applications

- Pharmaceutical

- Textile manufacturing

- Process cooling & heating

- Petroleum industry

- Rubber processing

- Metallurgy

- Plastic extrusion

- Injection molding

Properties

- Color

- Appearance

- Synthetic organic hydrocarbon, Clear, light yellow

- Odor

- Mild hydrocarbon odor

- Typical Properties

- Properties

Temperature

°CViscosity

mPa·sThermal

Conductivity

W/m·KSpecific

Heat

kJ/kg·KDensity

kg/m^{3}20 49 0.1306 1.549 1044 40 16.8 0.128 1.624 1030 60 8.3 0.1253 1.698 1016 80 4.9 0.1227 1.773 1001 100 3.3 0.1201 1.847 987 120 2.3 0.1174 1.922 973 140 1.7 0.1148 1.996 958 160 1.3 0.1122 2.071 944 180 1.1 0.1095 2.145 930 200 0.87 0.1069 2.22 915 220 0.72 0.1043 2.294 901 240 0.61 0.1016 2.369 887 260 0.52 0.099 2.443 873 280 0.45 0.0963 2.518 858 300 0.39 0.0937 2.592 844 320 0.35 0.0911 2.667 830 340 0.31 0.0884 2.742 815 350 0.29 0.0871 2.779 808 Vapor Pressure

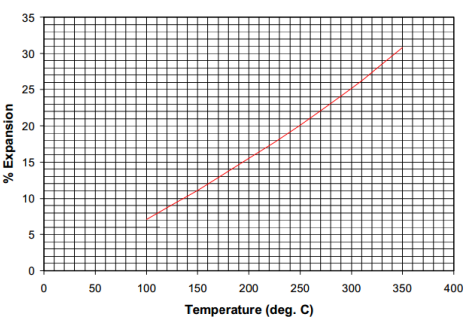

Temperature Vapor Pressure °C psi 140 0.001 160 0.007 180 0.025 200 0.073 220 0.17 240 0.39 260 0.78 280 1.42 300 2.9 320 4.57 340 8.12 350 10.15 Percent Expansion

| Value | Units | Test Method / Conditions | |

| Recommended Temperature Ranges (Closed systems) | 20 - 350 | °C | — |

| Recommended Temperature Ranges (Open systems) | 20 - 177 | °C | — |

| Pour Point | max. -34 | °C | — |

| Initial Boiling Point | 385.0 | °C | — |

| Flash Point (Closed) | 200.0 | °C | — |

| Autoignition Temperature | 450.0 | °C | — |

| Max Film Temperature | 380.0 | °C | — |

| Min Pumpability Limit | -5.0 | °C | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Quantity & Availabiliy

Dynalene HT is usually purchased in 1, 5 and 55-gallon containers, but tanker quantities are also available.